Residual life prediction method of rotation machinery under influence of health management behavior

A technology of health management and life prediction, which is applied in the direction of machine/structural component testing, measuring devices, complex mathematical operations, etc., and can solve problems such as unconsidered maintenance activities and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention aims to realize the prediction of the remaining life of the rotating machinery. Firstly, the state monitoring data (such as the monitoring data of the surface vibration of the casing and the vibration of the shaft) of the rotating machinery in actual operation is obtained by means of state monitoring, and the data that can reflect its health status are extracted. Based on performance degradation data (such as vibration amplitude data), a performance degradation model is established; based on this model, the first-arrival time distribution of the degradation process is solved, and then the remaining life distribution is predicted using the first-arrival time distribution;

[0022] In the above-mentioned embodiment, a stochastic degradation model considering the influence of health management behavior is also established, and the unknown parameters of the degradation model and the parameters in the maintenance intensity process are estimated to derive ...

Embodiment 2

[0025] The difference with embodiment 1 is:

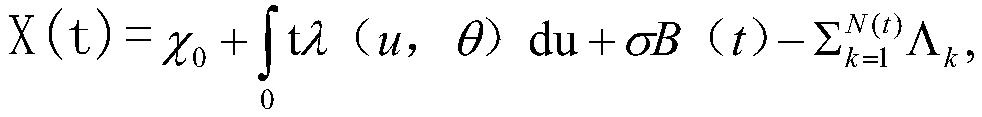

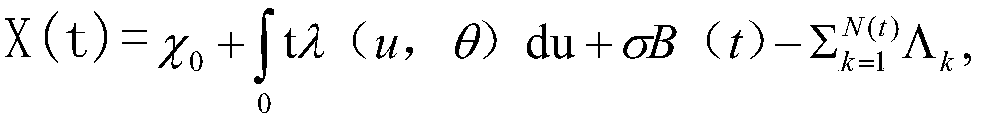

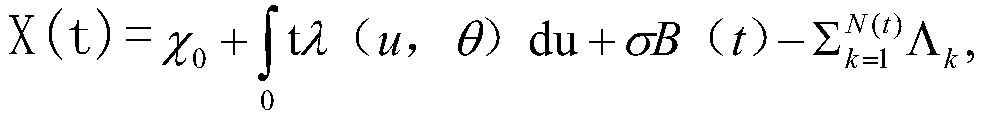

[0026] According to the impact of health management behavior, the random degradation process of rotating machinery can be described by the following random process:

[0027]

[0028] in It is a composite Poisson process, describing the frequency of arrival of external health management behaviors, {Λ k , k≥1} is an independent and identically distributed random variable, describing the random impact of each health management behavior on the equipment degradation state;

[0029] For the stochastic degradation process above, the estimation of the unknown parameters in the degradation model consists of two parts: the parameters of the composite Poisson process, denoted as Ξ 1 ; other parameters, expressed as Ξ 2 ; Assume that the observed health management behavior arrival time data is and repair strength data for Based on this, it can be obtained by the method of maximum likelihood estimation that parameter Ξ 2 The estim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com