Method for measuring tungsten trioxide contentofhigh-impurity tungstate

A technology of tungsten trioxide and a determination method, which is applied in the preparation of test samples and the measurement of color/spectral characteristics, etc., can solve the problems of difficult determination of tungsten trioxide, reduced work efficiency, and inability to report accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

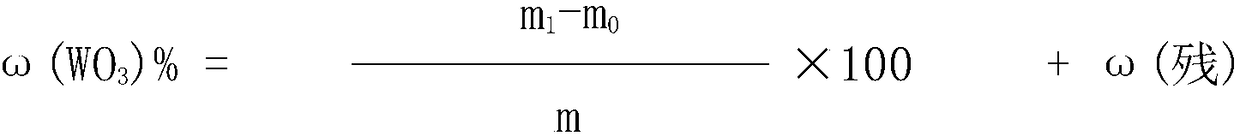

Method used

Image

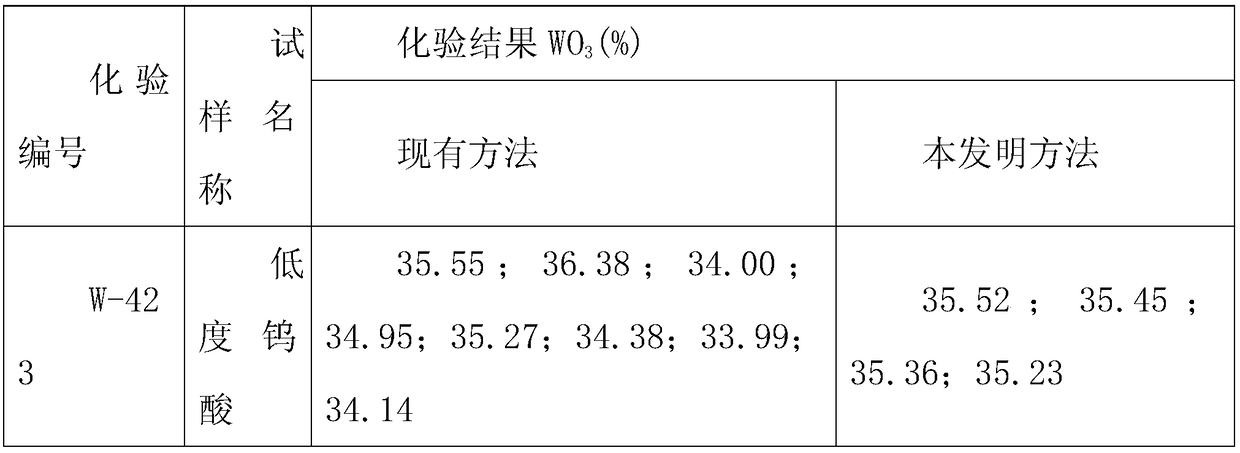

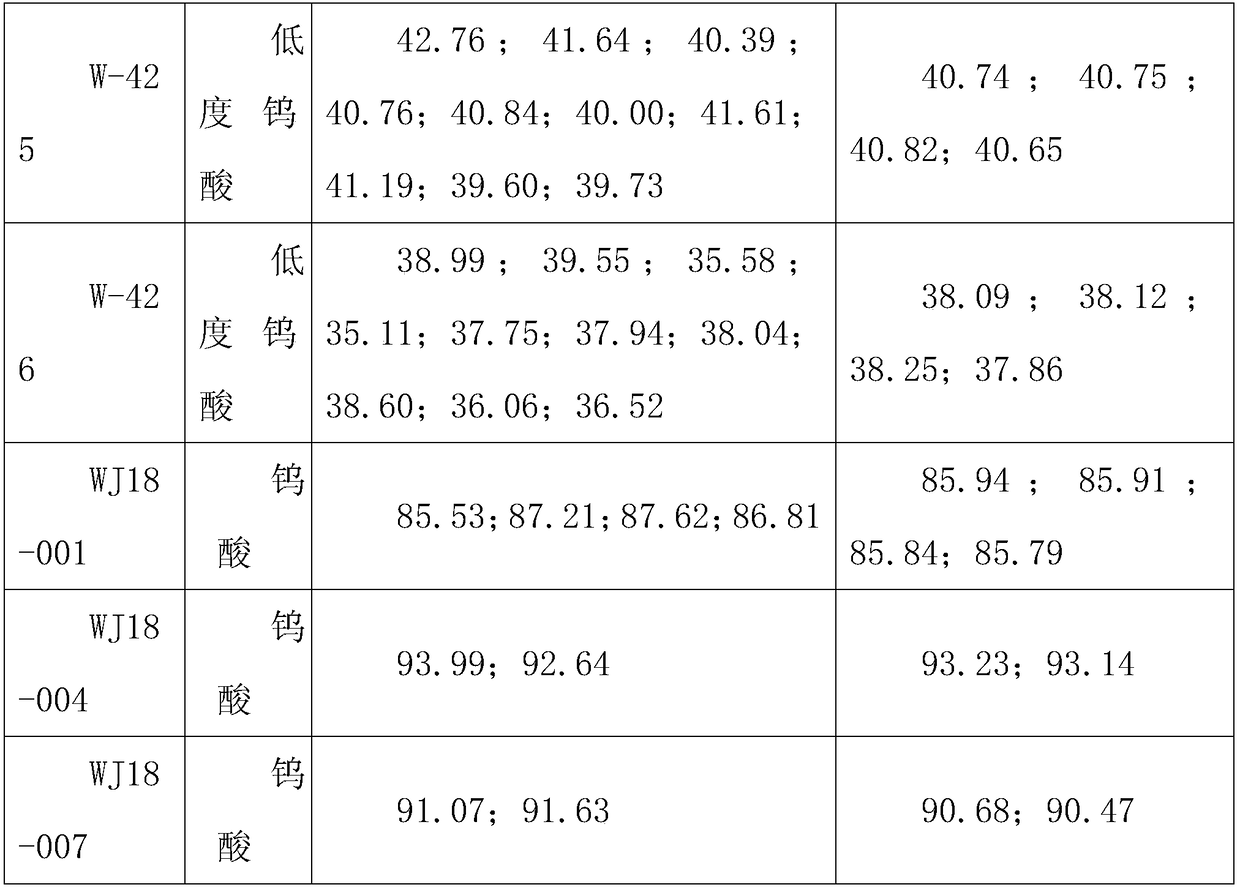

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

[0024] Sample determination

[0025] Weigh about 0.5g of sample into a 150mL beaker, add 5mL of 200g / L NaOH solution and 3mL of 10% hydrogen peroxide, put it on an electric furnace to decompose at low temperature to near dryness, remove it, cool it slightly, dilute with water to 30-60mL, boil After half an hour, remove and let stand to cool; filter into a 250 mL beaker with slow qualitative filter paper, and wash with hot water 8 to 10 times.

[0026] Add 1 to 2 drops of 0.1% methyl orange indicator to the filtrate, adjust the solution to red with (1+1) hydrochloric acid, add water to about 100 mL, add 3 mL of 5% cinchonine solution under constant stirring, and heat it on an electric furnace to Slightly boil, remove and let stand. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com