Patents

Literature

33 results about "Cinchonine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

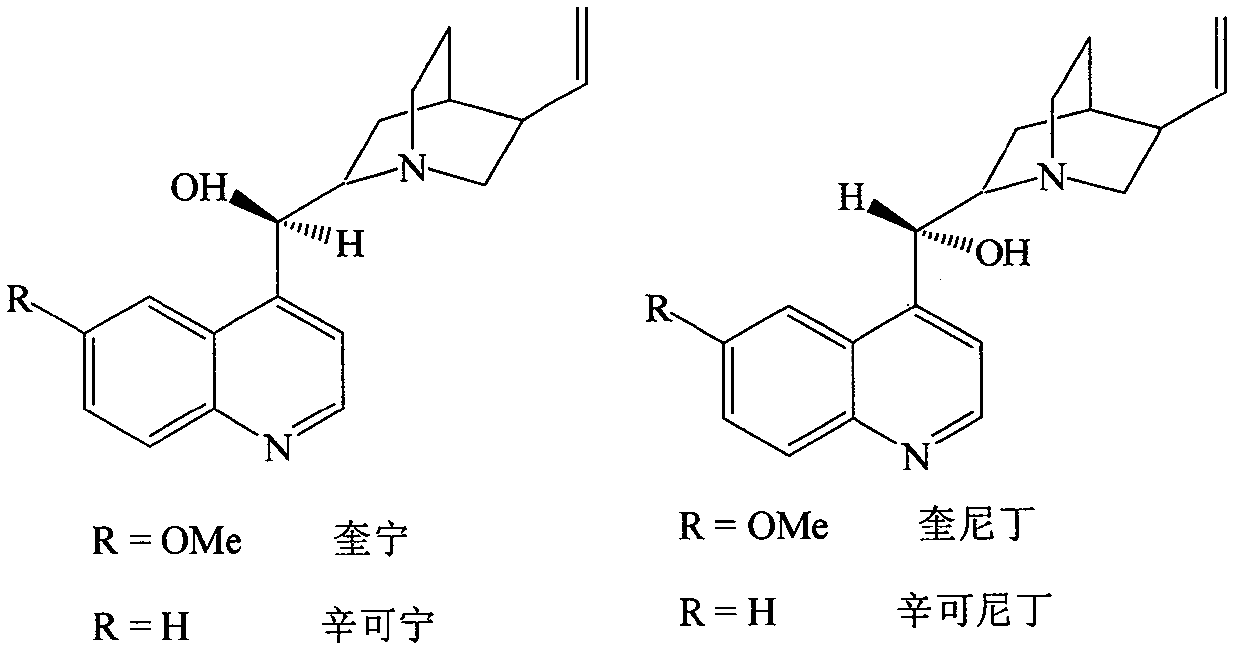

Cinchonine is an alkaloid found in Cinchona officinalis. It is used in asymmetric synthesis in organic chemistry. It is a stereoisomer and pseudo-enantiomer of cinchonidine.

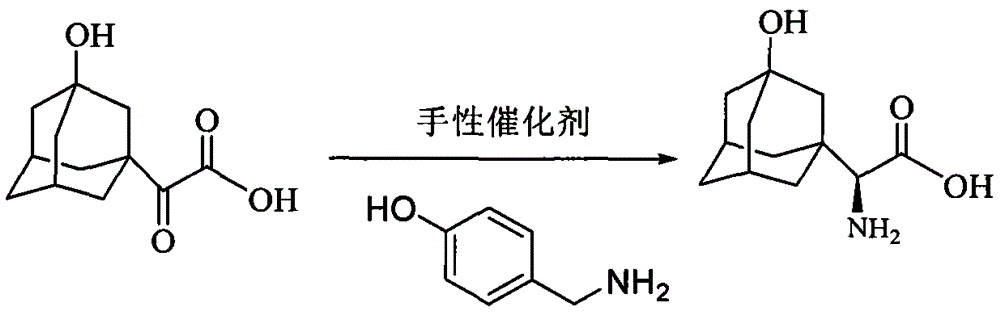

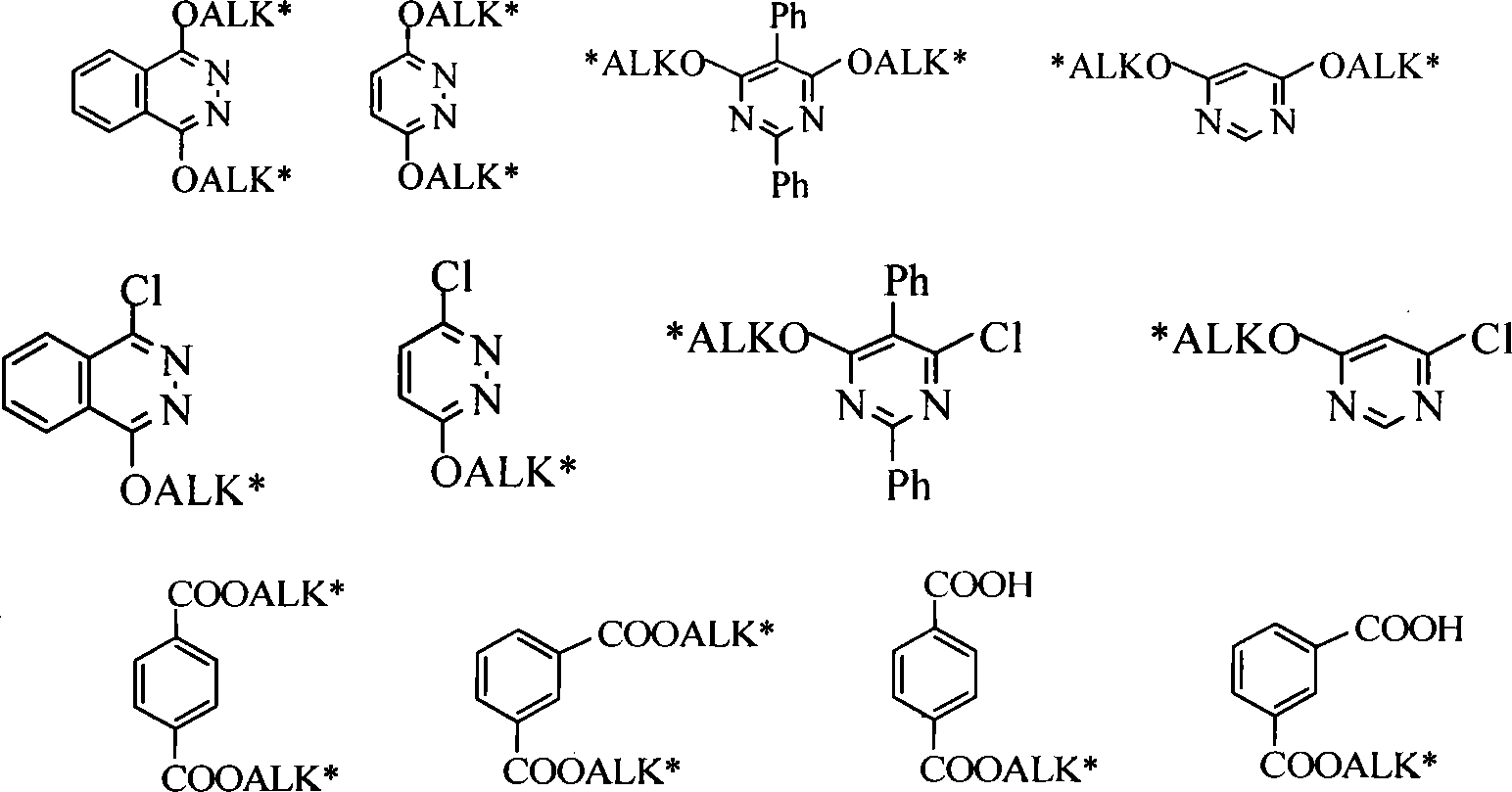

Macromolecule immobilized cinchonine alkaloid ligand, synthesis method and use thereof

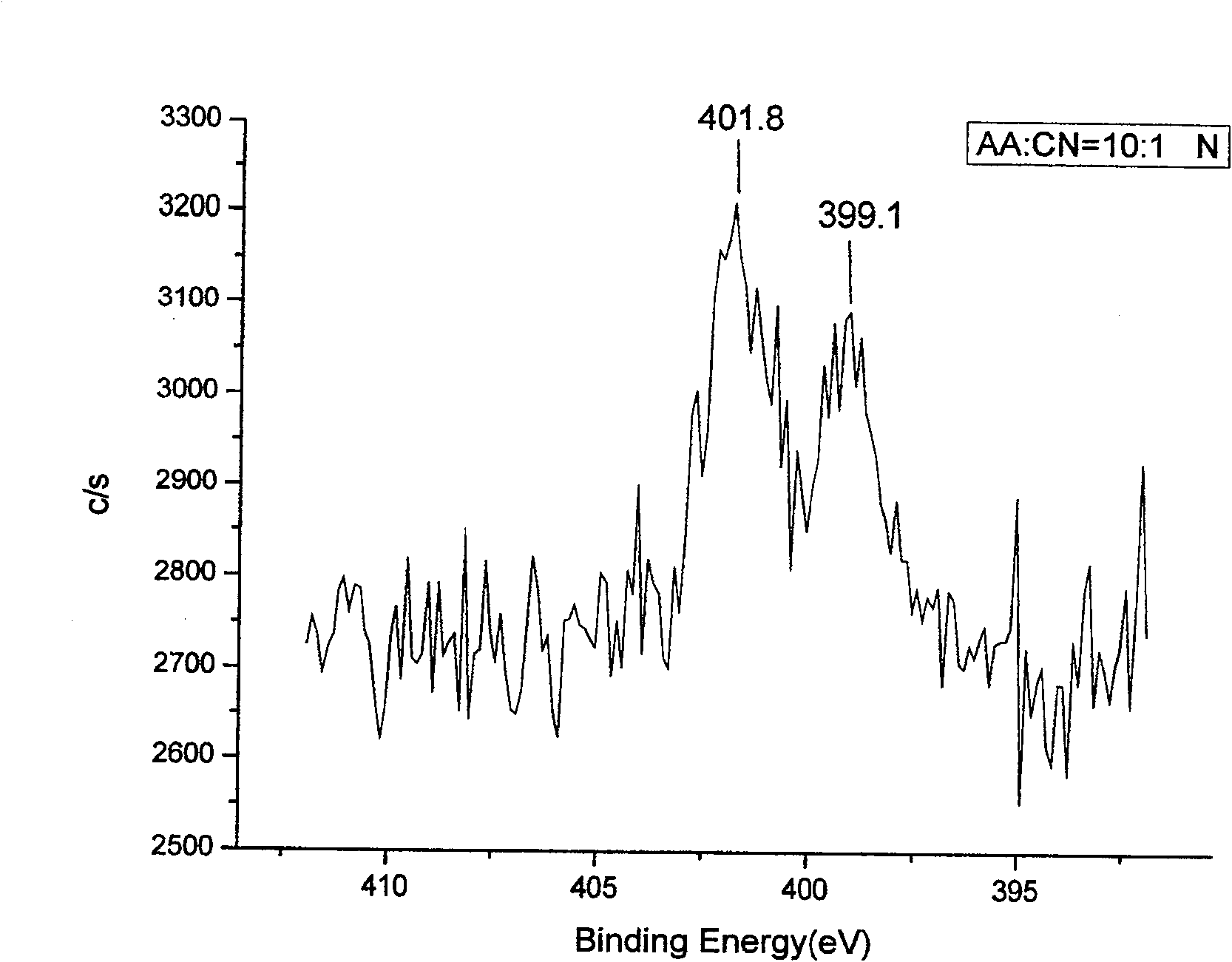

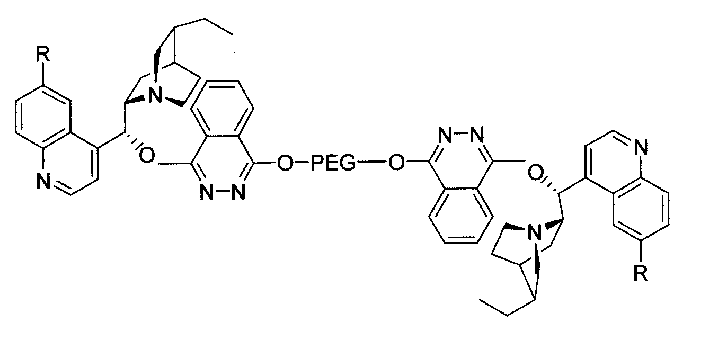

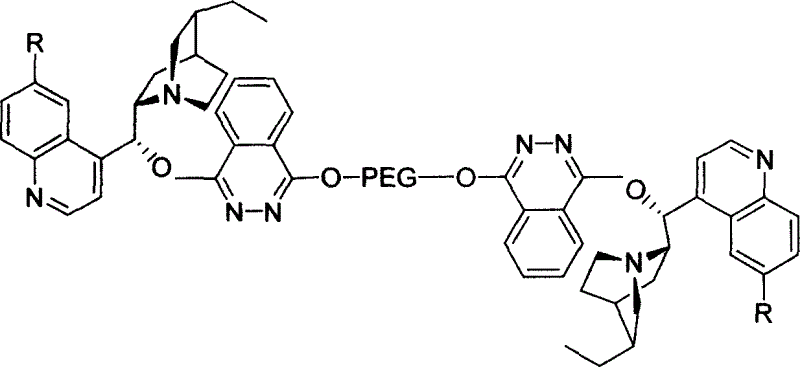

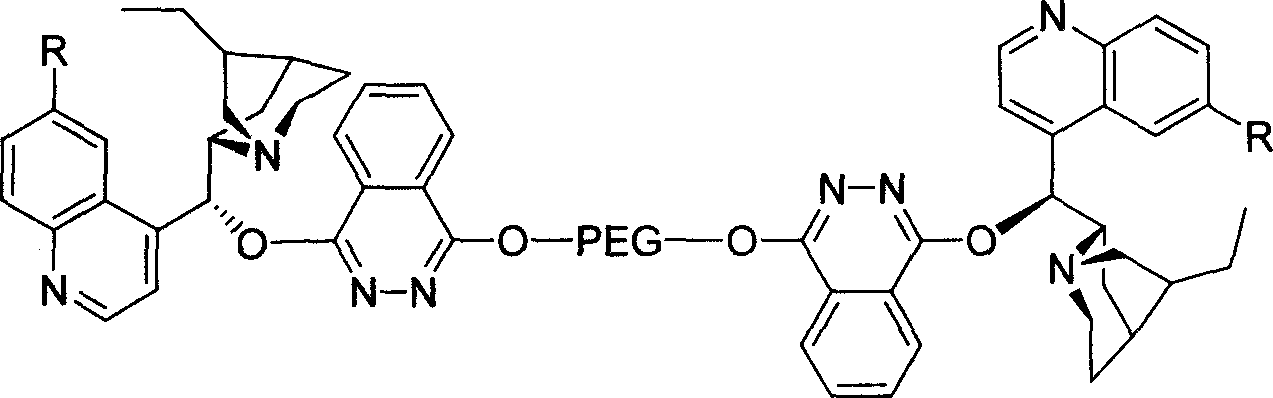

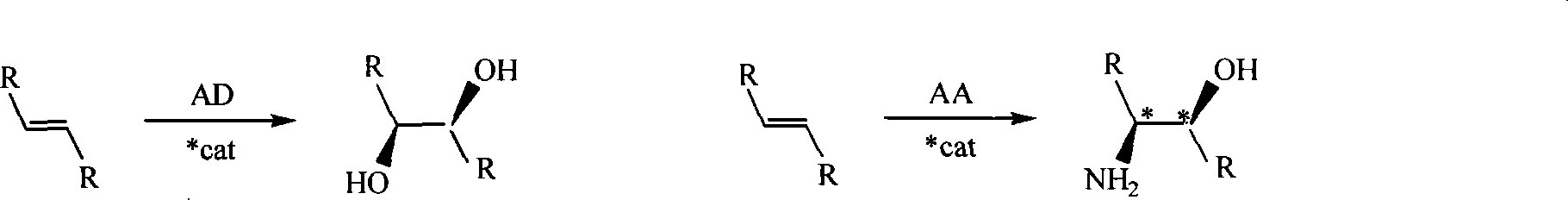

InactiveCN1523024ADoes not reduce activityHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsCinchonine

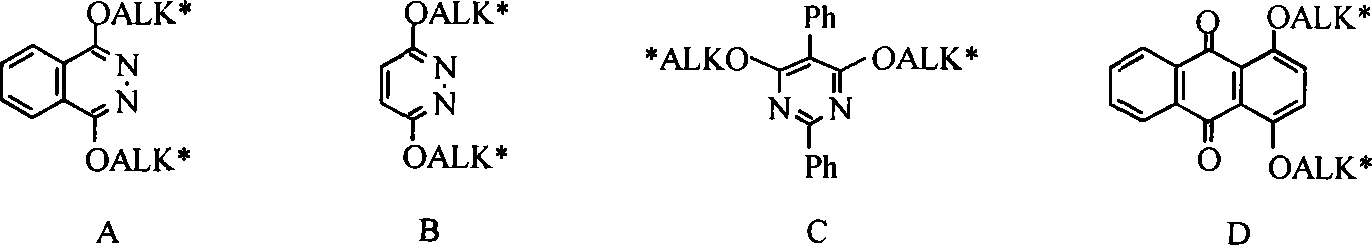

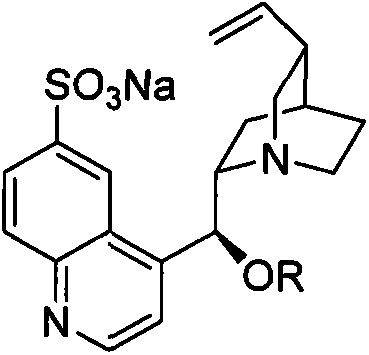

The present invention relates to homogeneous macromolecular immobilized dicinchonine alkaloid ligands. Said invention provids their structur formulas, and said ligand are made up by utilizing chemical bond mode to connect the chiral cinchonine ligand onto the polyethylene glycol. Said ligand can be used as catalyst for olefine asymmetric reaction, olefine hydroxyamination reaction and dihydroxylation reaction, and the yield and selectivity are high.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

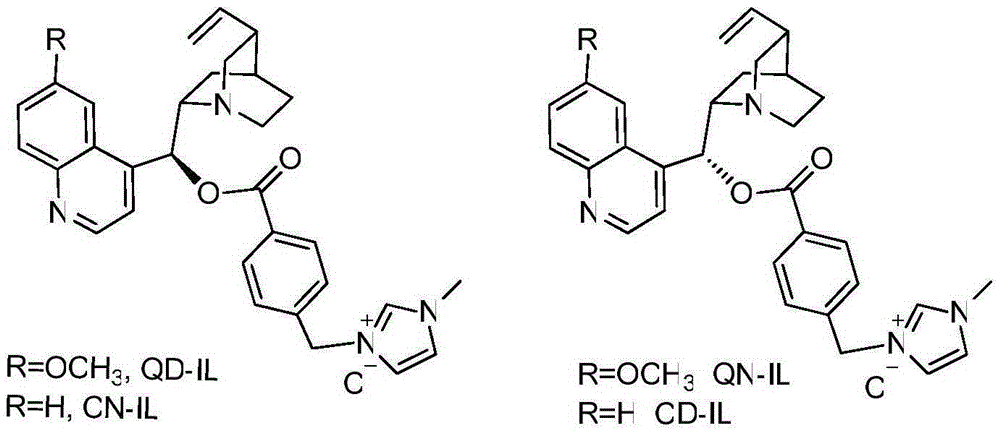

Preparation of imidazole type ionic liquid derived by cinchona alkaloid

InactiveCN105330662AHigh catalytic activityIncrease profitOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIonic liquidEnantio selectivity

The invention discloses the preparation of imidazole type ionic liquid derived by cinchona alkaloid. The preparation is characterized by adopting quinine or cinchonine to modify 9-hydroxyl of the cinchona alkaloid; carrying out a replacement reaction on chloride salt of obtained imidazole type ionic liquid and inorganic metal salt; preparing imidazole type ionic liquid catalysts of different anions. Compared with the prior art, the preparation disclosed by the invention has the advantages that the catalytic activity is high, the catalysts are easily separated and recycled and can be reused again, the preparation is simple, post-processing is easy, the stability of the catalysts is greatly increased, the application range of the catalysts in a micromolecular organic asymmetric reaction is expanded, reaction conditions are optimized, reaction requirements are reduced, the catalytic activity and the enantioselectivity of a chiral imidazole type ionic liquid catalyst in an asymmetric reaction are further increased, and great significance is obtained for researching medicinal chemistry and medical intermediate compounds.

Owner:EAST CHINA NORMAL UNIV

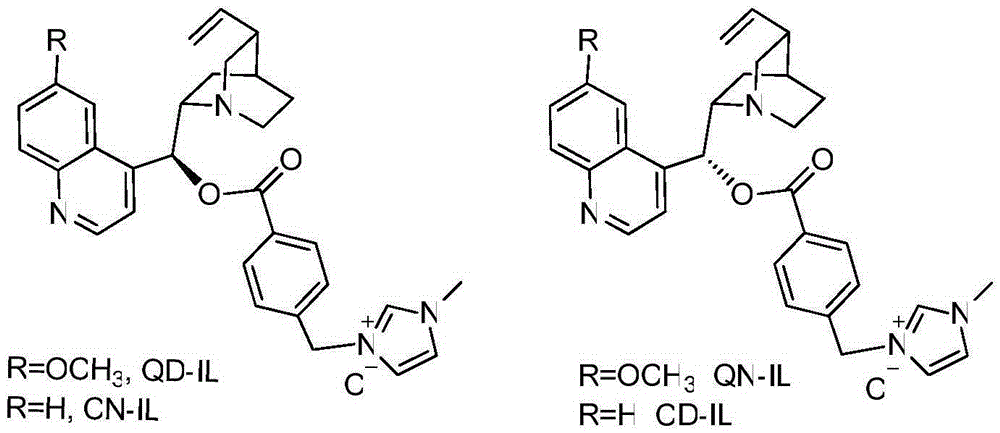

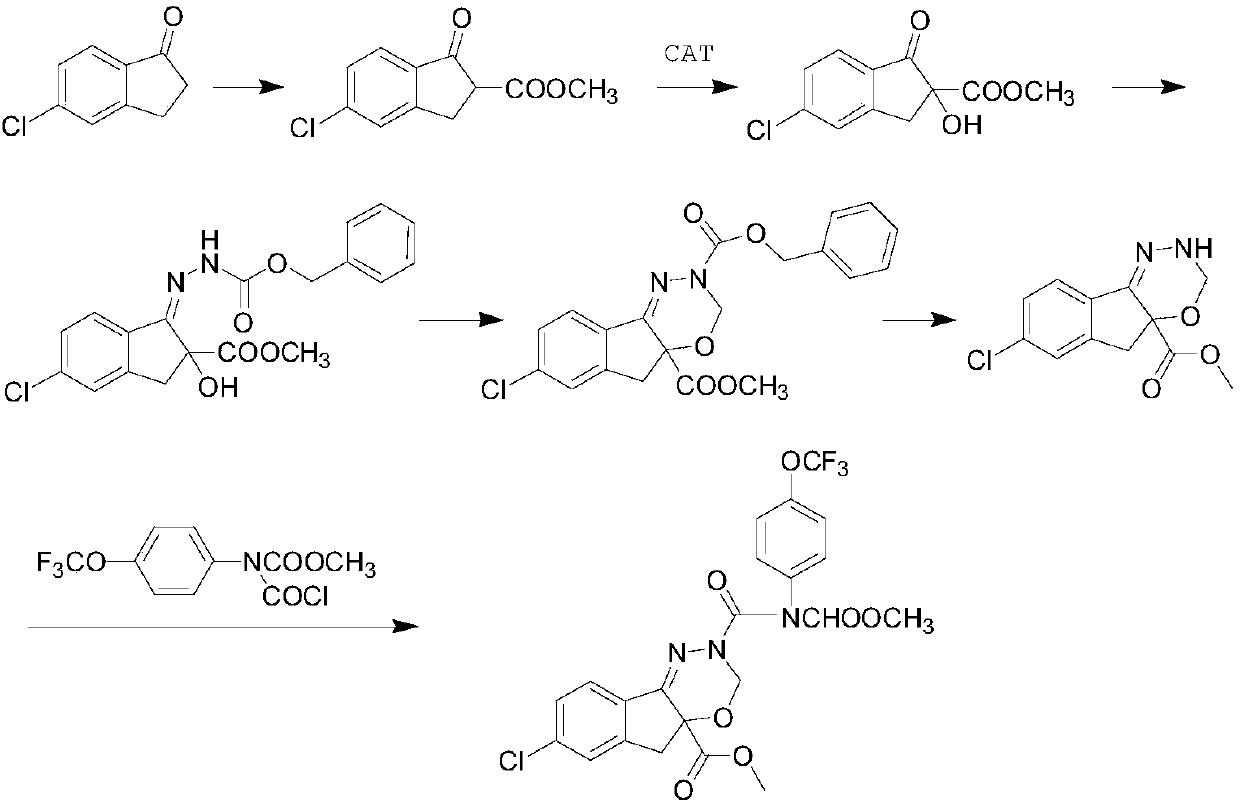

Preparation method of (+)methyl 5-chloro-2,3-dihydro-2-hydroxy-1-oxo-1H-indene-2-carboxylate

InactiveCN105461552AIncrease contentChange yieldOrganic compound preparationCarboxylic acid esters preparationMethyl carbonateCarboxylic salt

The invention relates to the field of pesticide synthesis, and in particular provides a preparation method of an intermediate of indoxacarb, namely (+)methyl 5-chloro-2,3-dihydro-2-hydroxy-1-oxo-1H-indene-2-carboxylate, and 5-chloro-1-indanone, dimethyl carbonate, sodium hydride, cumene hydroperoxide and cinchonine are mainly adopted as reactants, and a double dropping way of the cumene hydroperoxide and 5-chloro-2-methoxycarbonyl group-1-indanone is adopted, the disadvantages in the prior art of low yield and low content of S-isomer are changed, the yield is improved, the cost is reduced, and the content of an effective body is improved.

Owner:JINGBO AGROCHEM TECH CO LTD

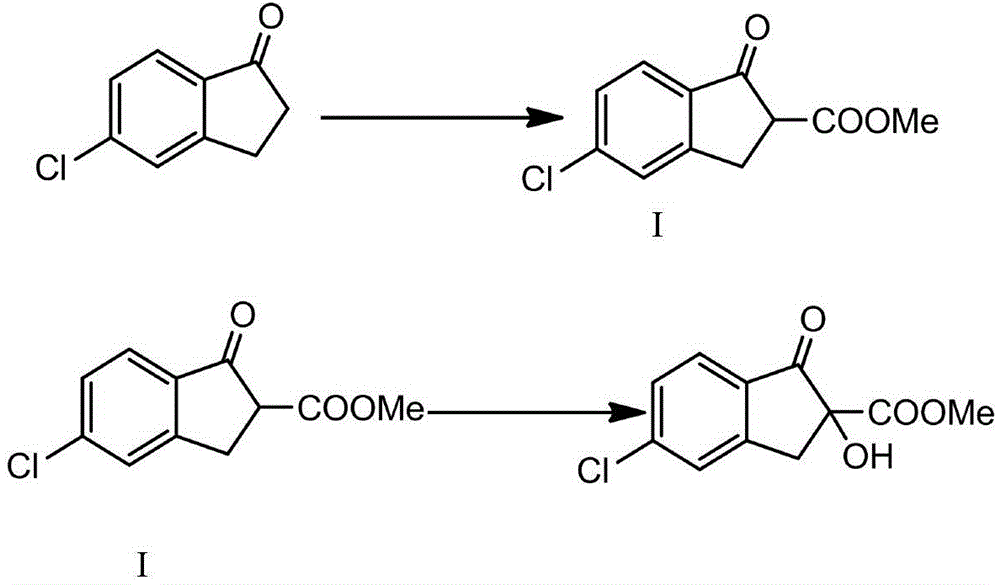

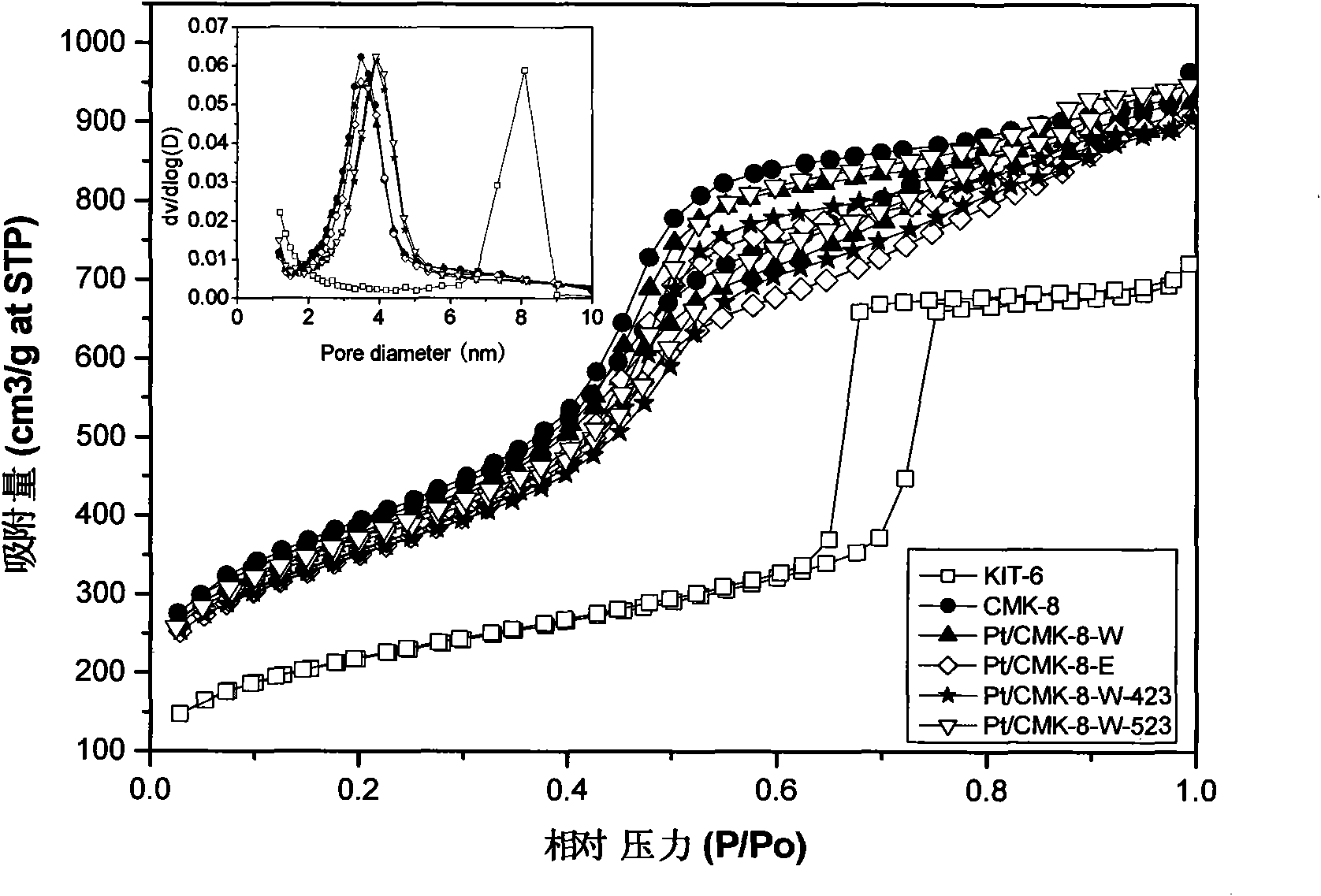

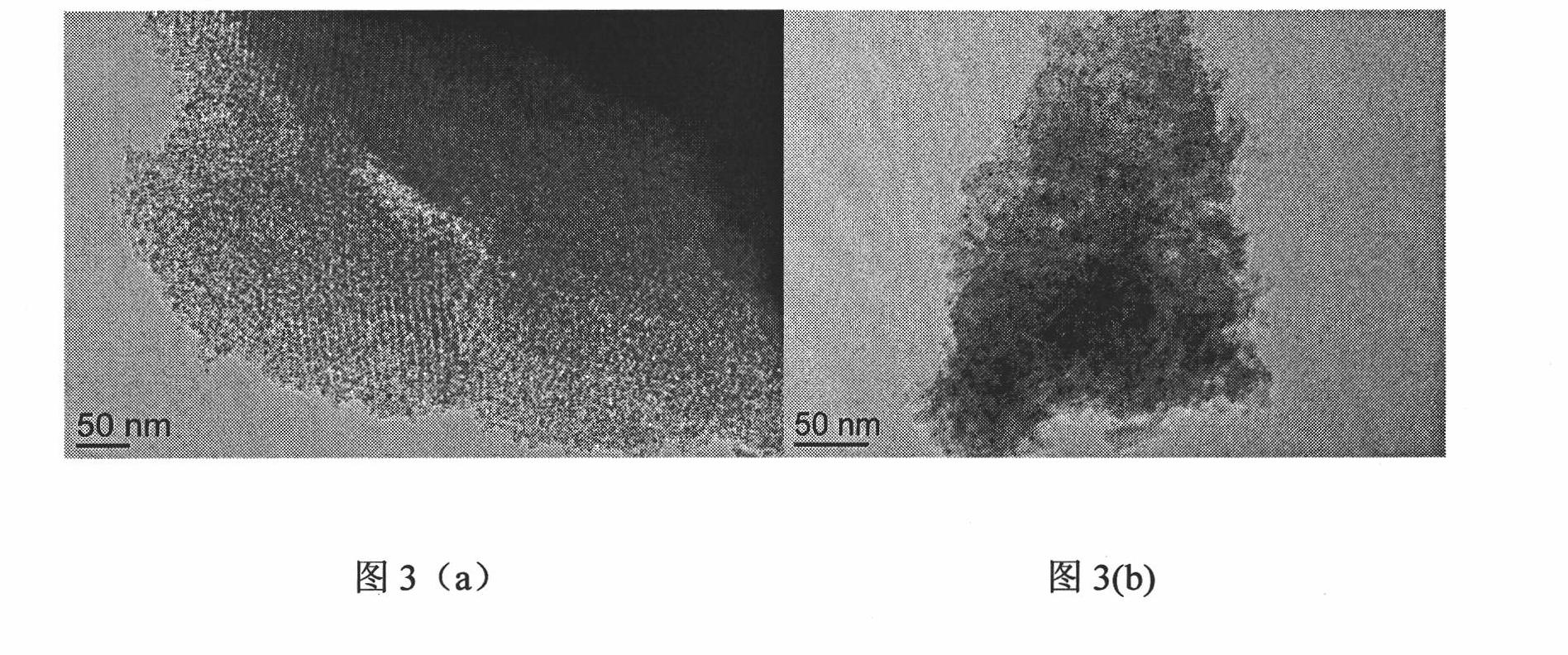

Application of ordered mesoporous carbon material-loaded platinum catalyst in alpha-keto ester asymmetrical catalytic hydrogenation reaction

InactiveCN102093218AImprove stabilityNot easy to loseOrganic compound preparationCarboxylic acid esters preparationSolventChrysolophus pictus

The invention provides application of an ordered mesoporous carbon material-loaded platinum catalyst in an alpha-keto ester asymmetrical catalytic hydrogenation reaction. The ordered mesoporous carbon material-loaded platinum catalyst is subjected to pretreatment at the atmosphere of hydrogen; and then the pre-treated ordered mesoporous carbon material-loaded platinum catalyst, golden pheasant alkaloid, solvent and alpha-keto ester are subjected to an asymmetrical catalytic hydrogenation reaction in a reaction kettle by a virtue of introducing hydrogen under the condition of electromagnetic stirring. In the invention, the ordered mesoporous carbon material-loaded platinum catalyst is subjected to chirality modification with cinchonidine or cinchonine, so as to represent an excellent catalytic property in the alpha-keto ester asymmetrical catalytic hydrogenation reaction.

Owner:EAST CHINA NORMAL UNIV

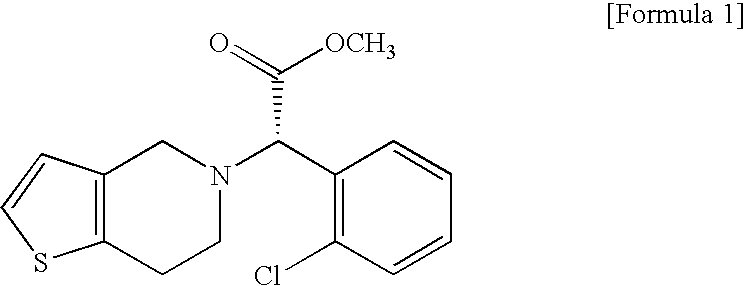

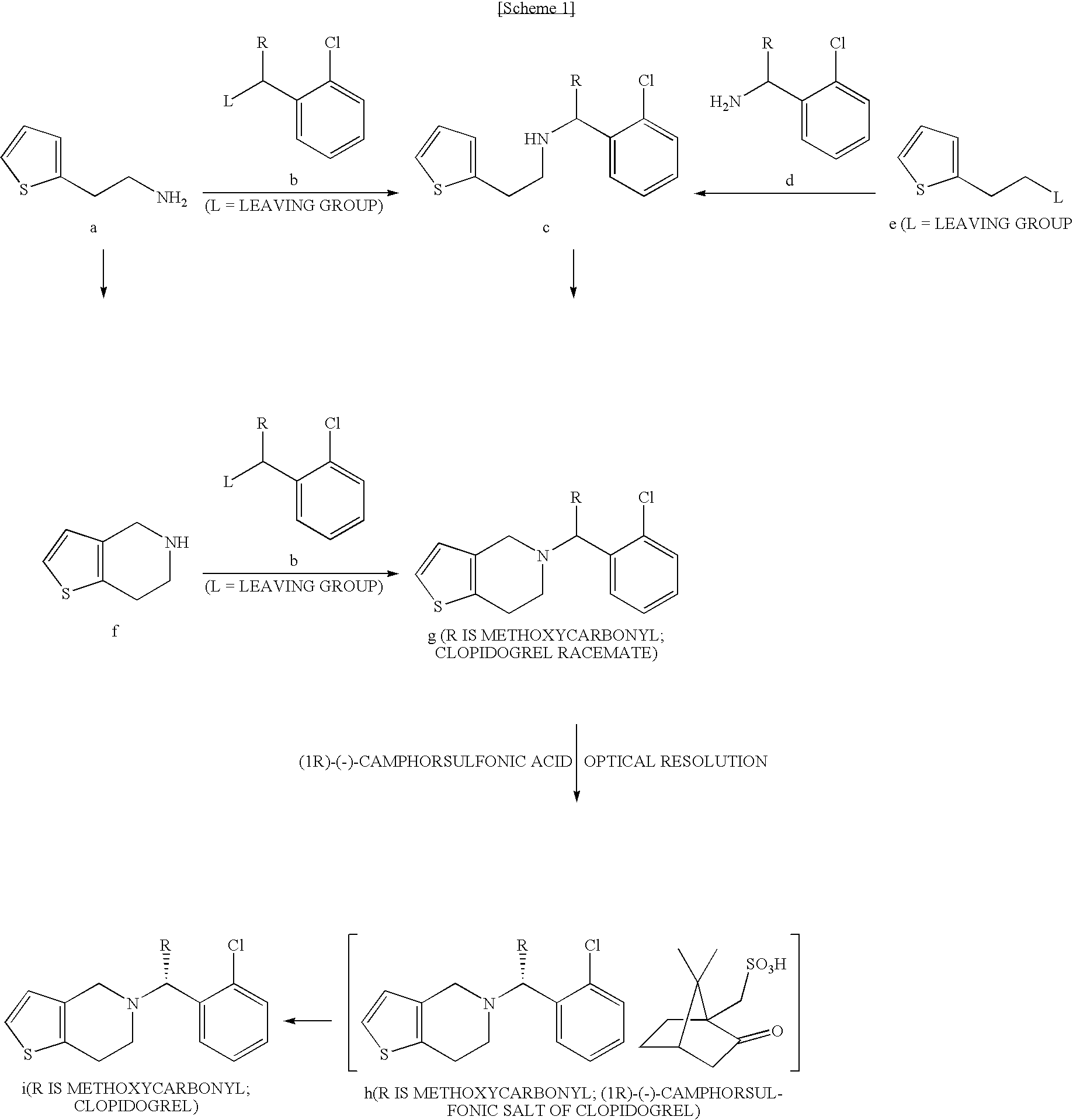

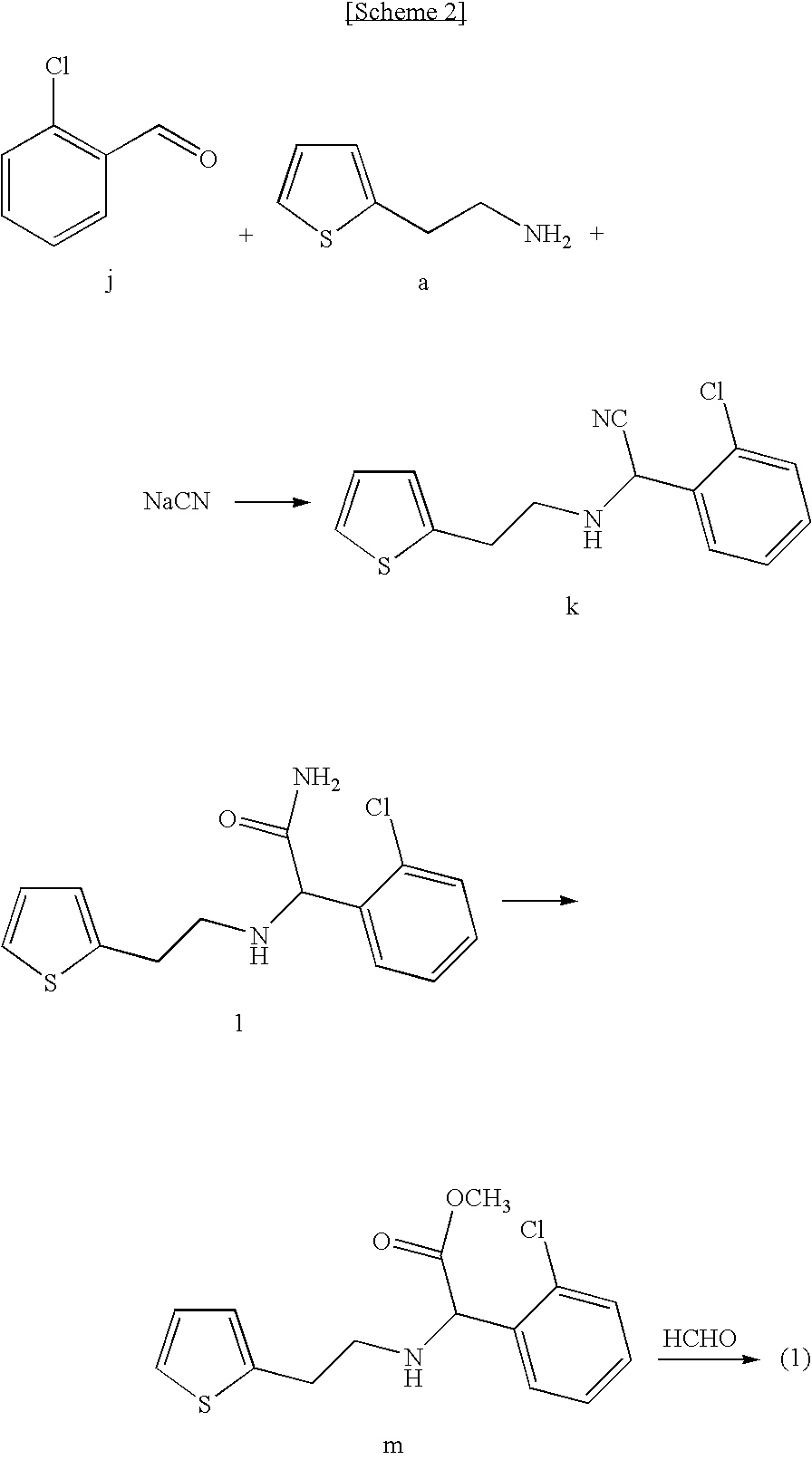

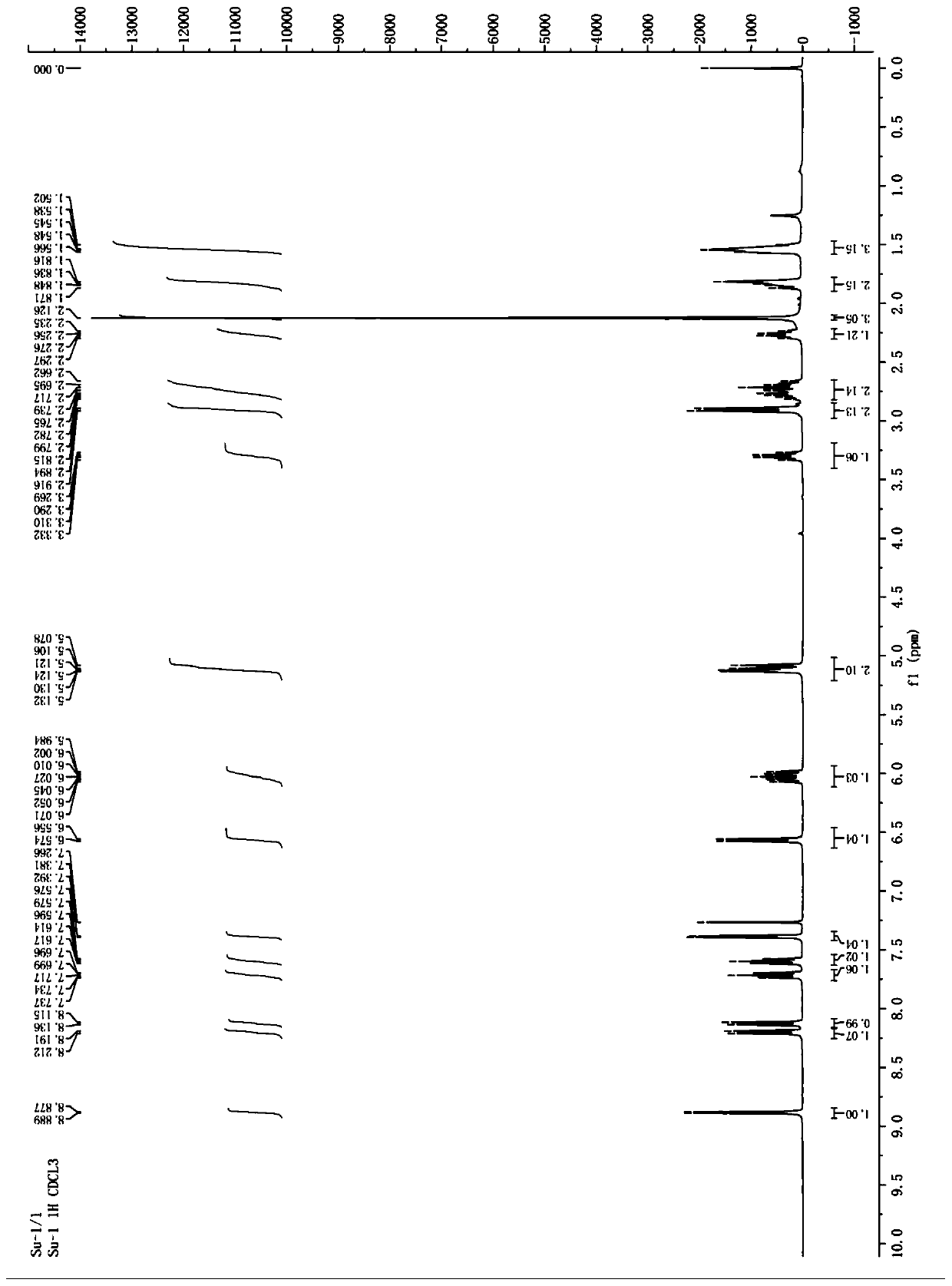

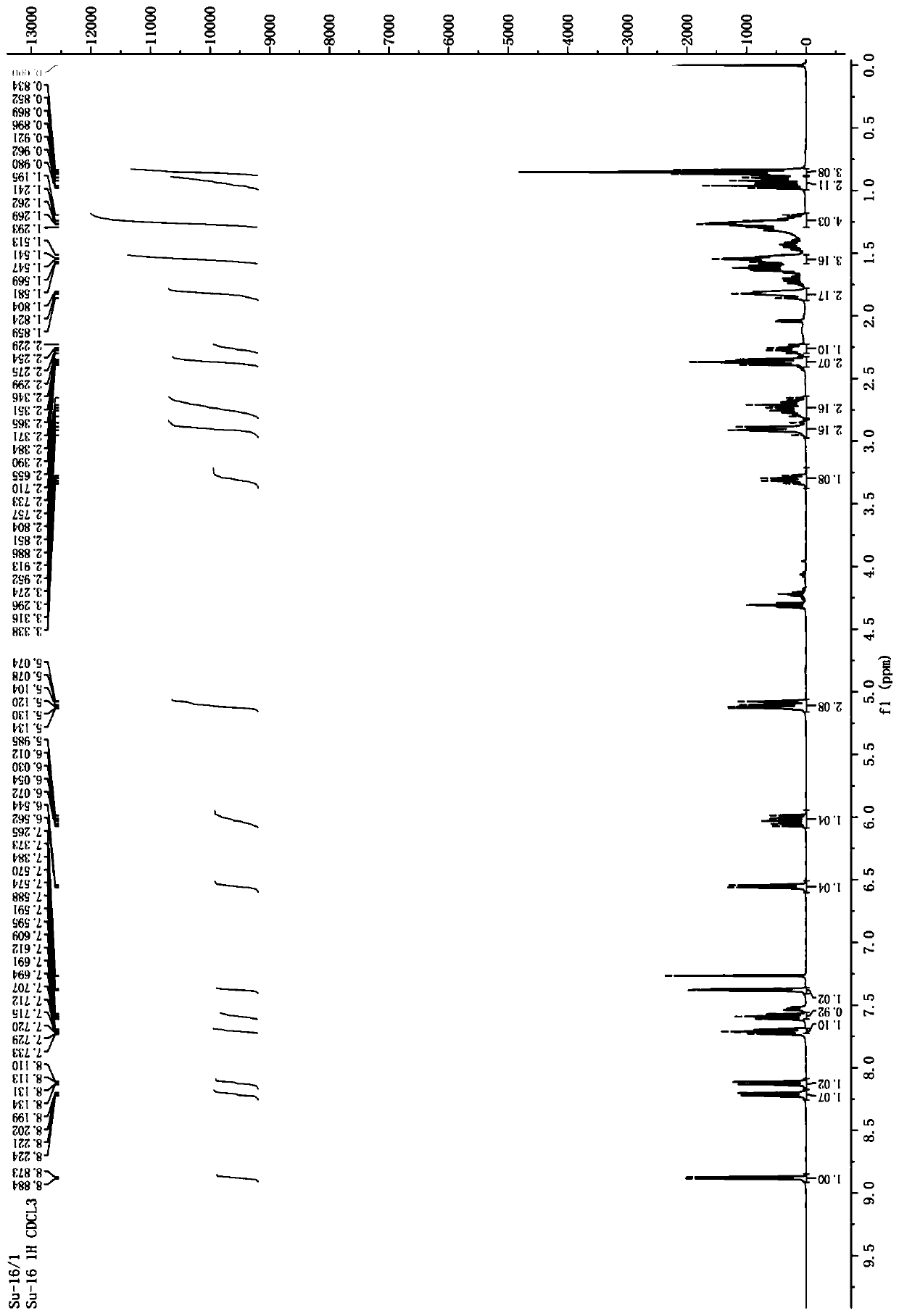

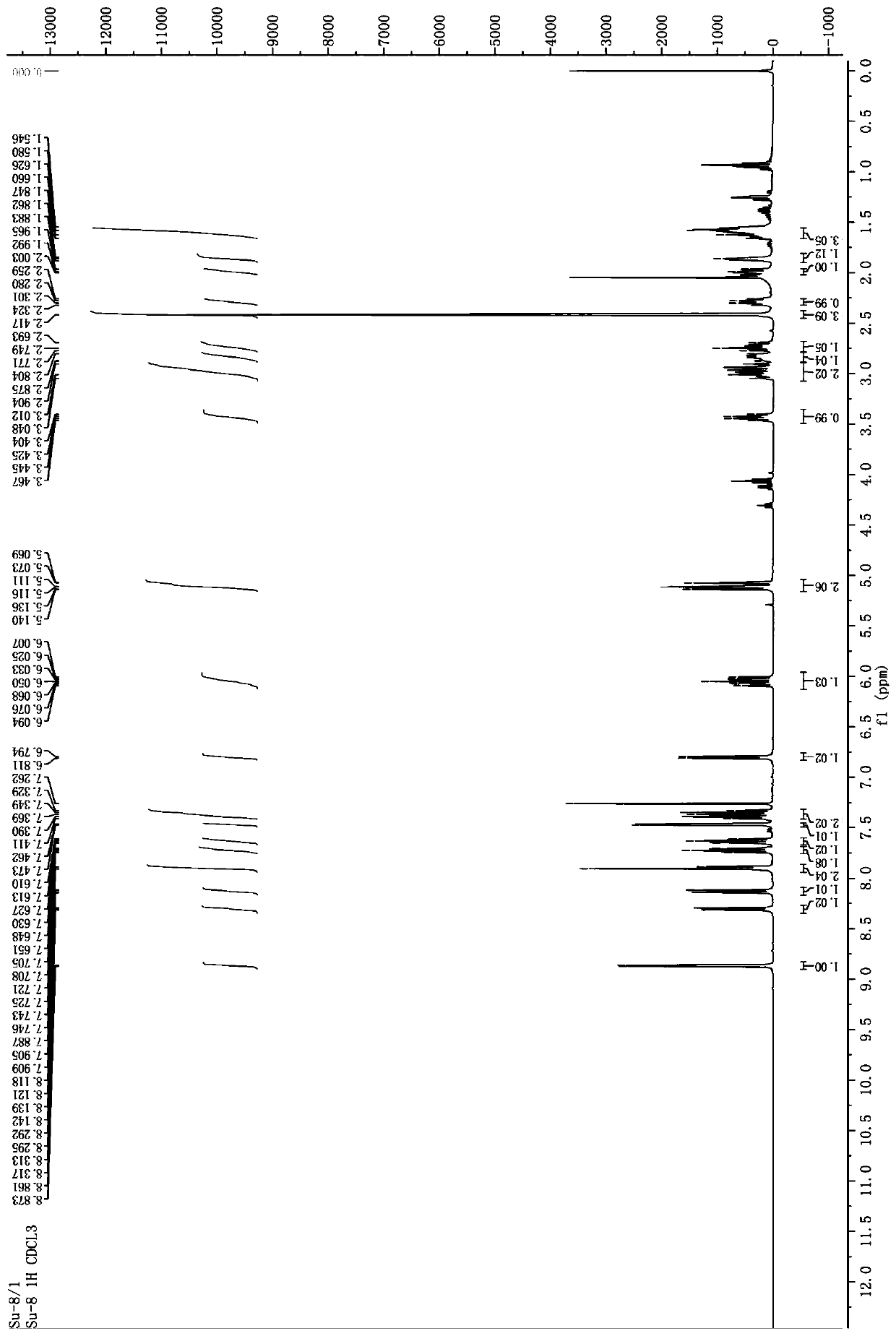

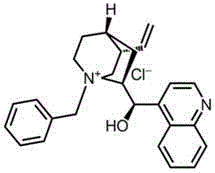

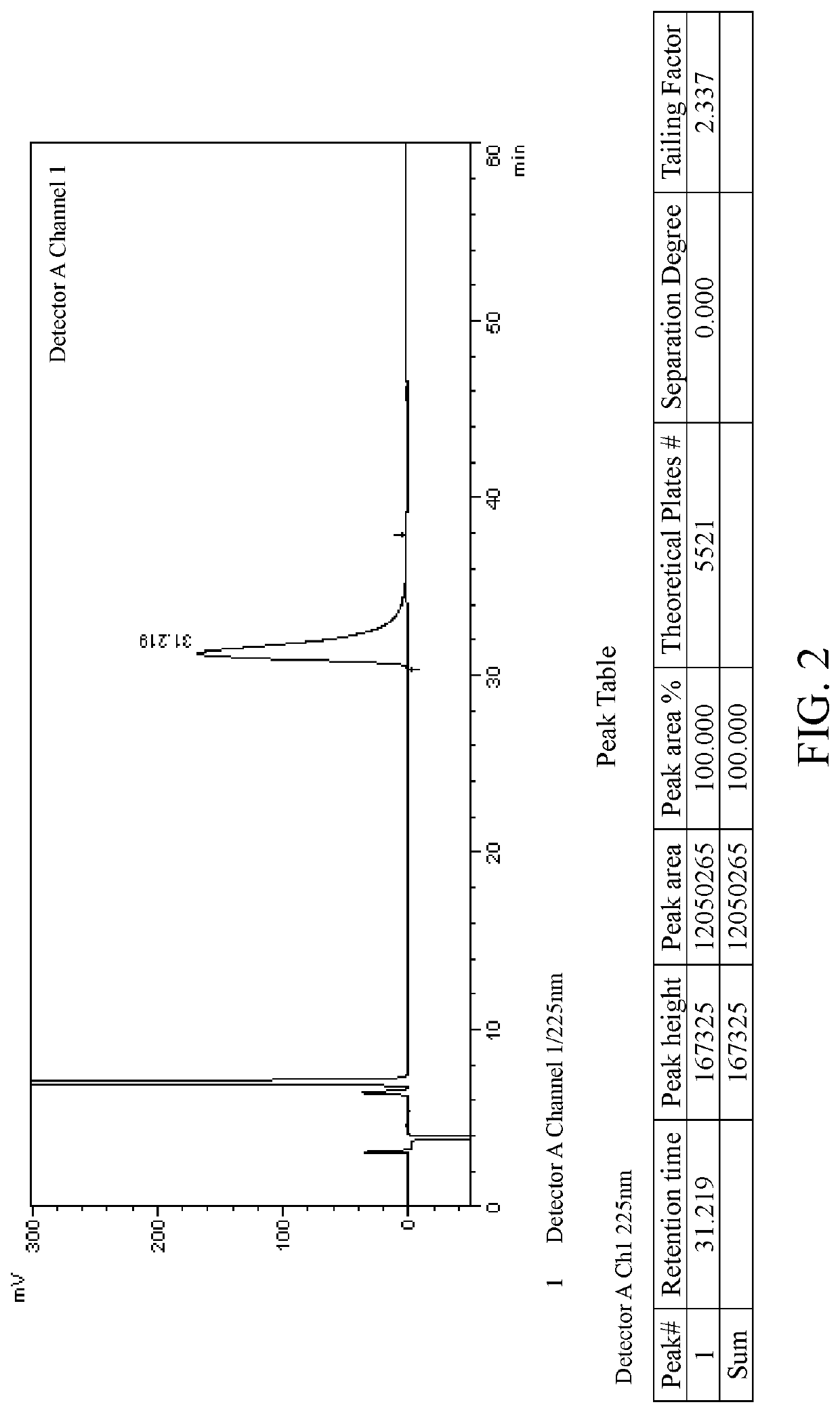

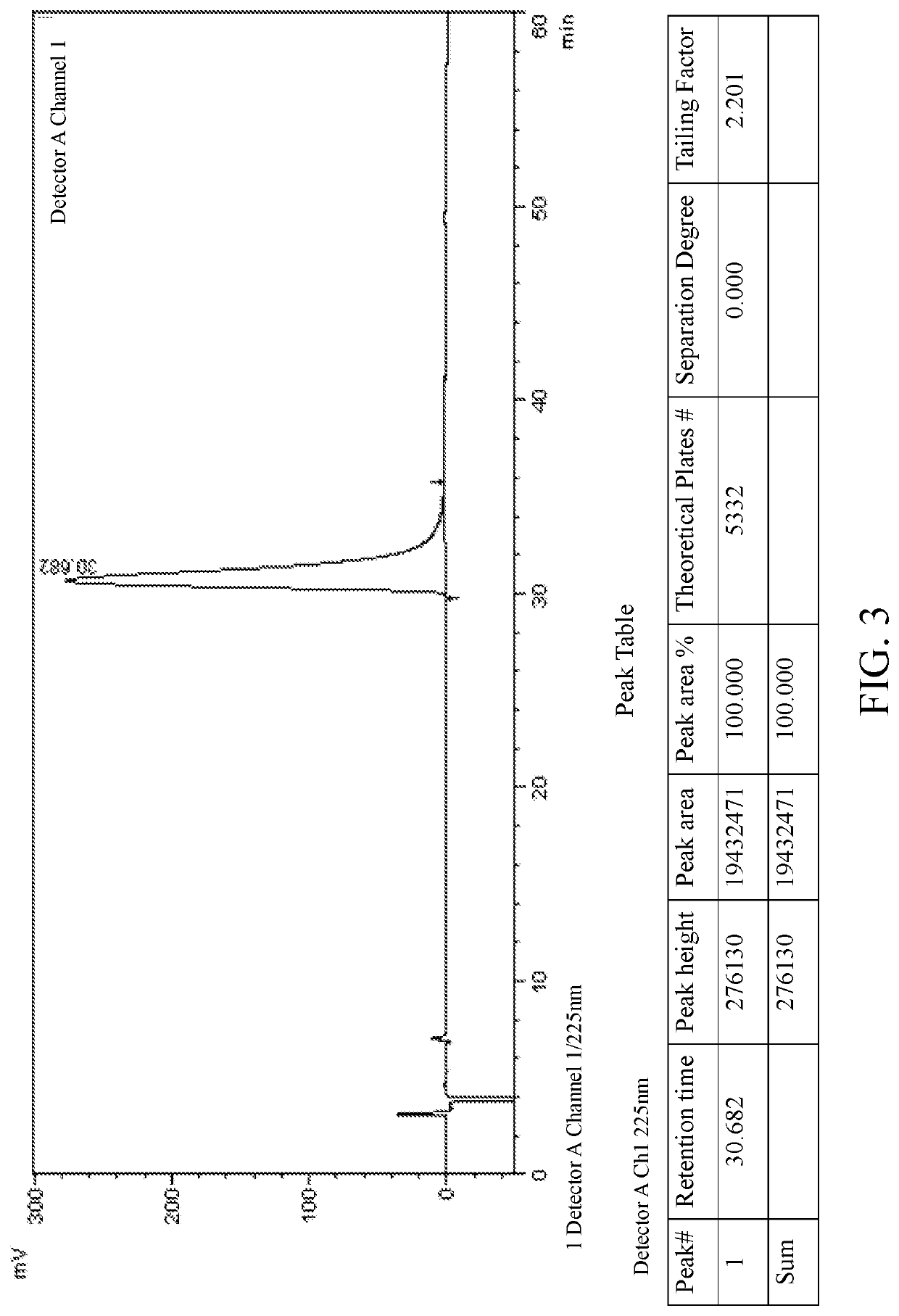

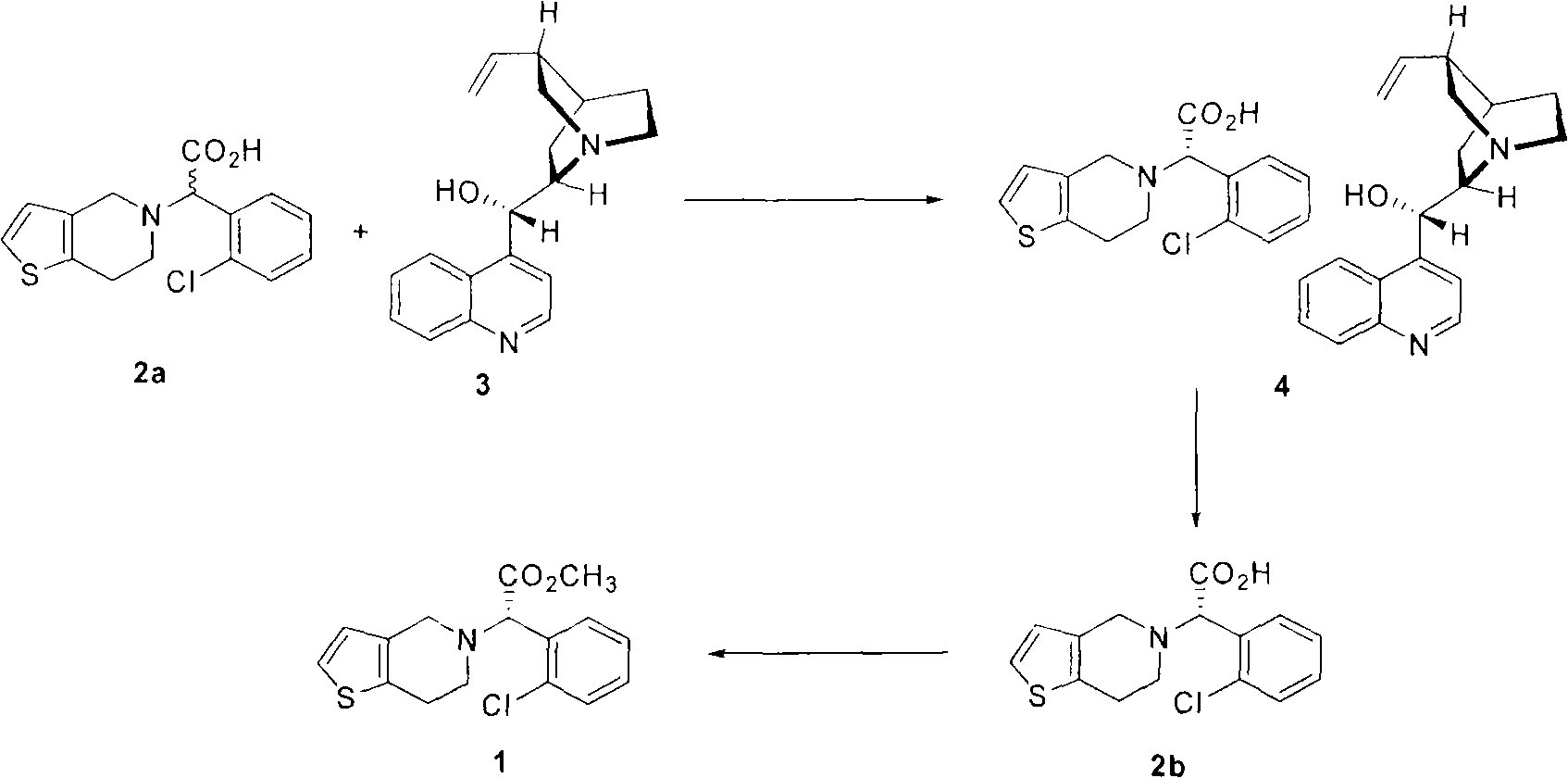

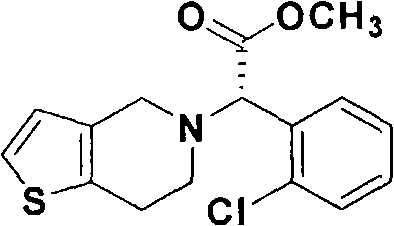

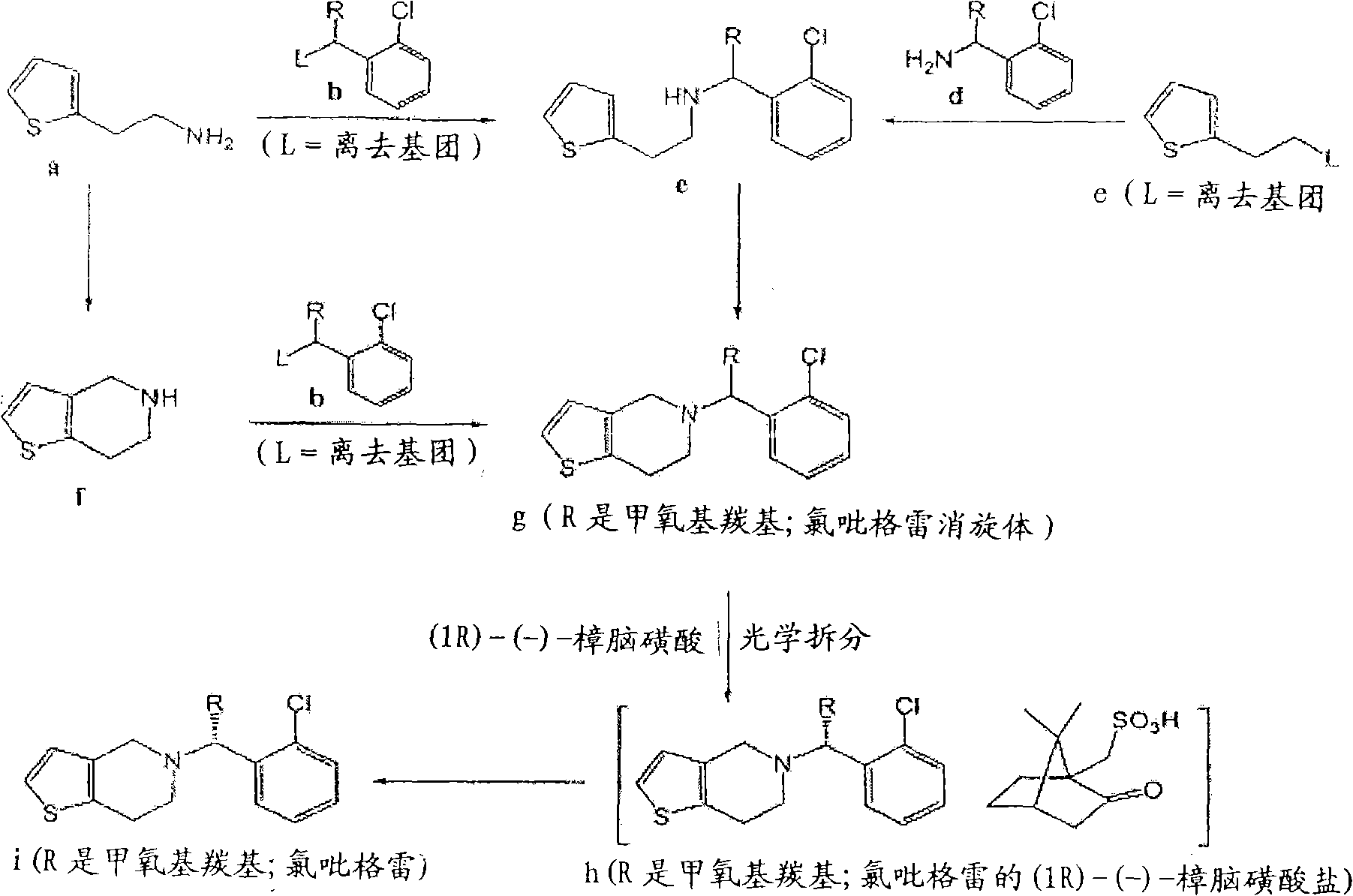

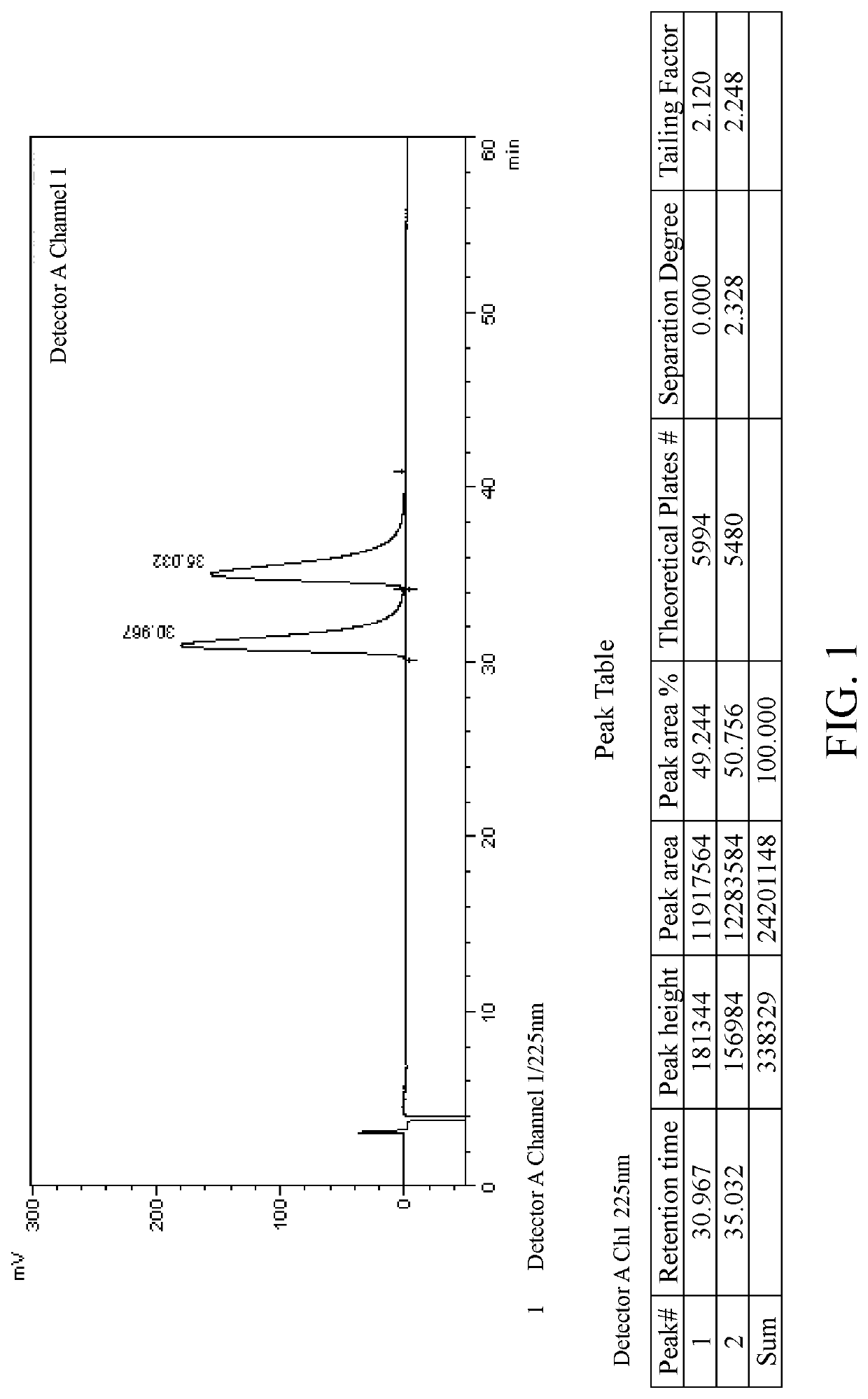

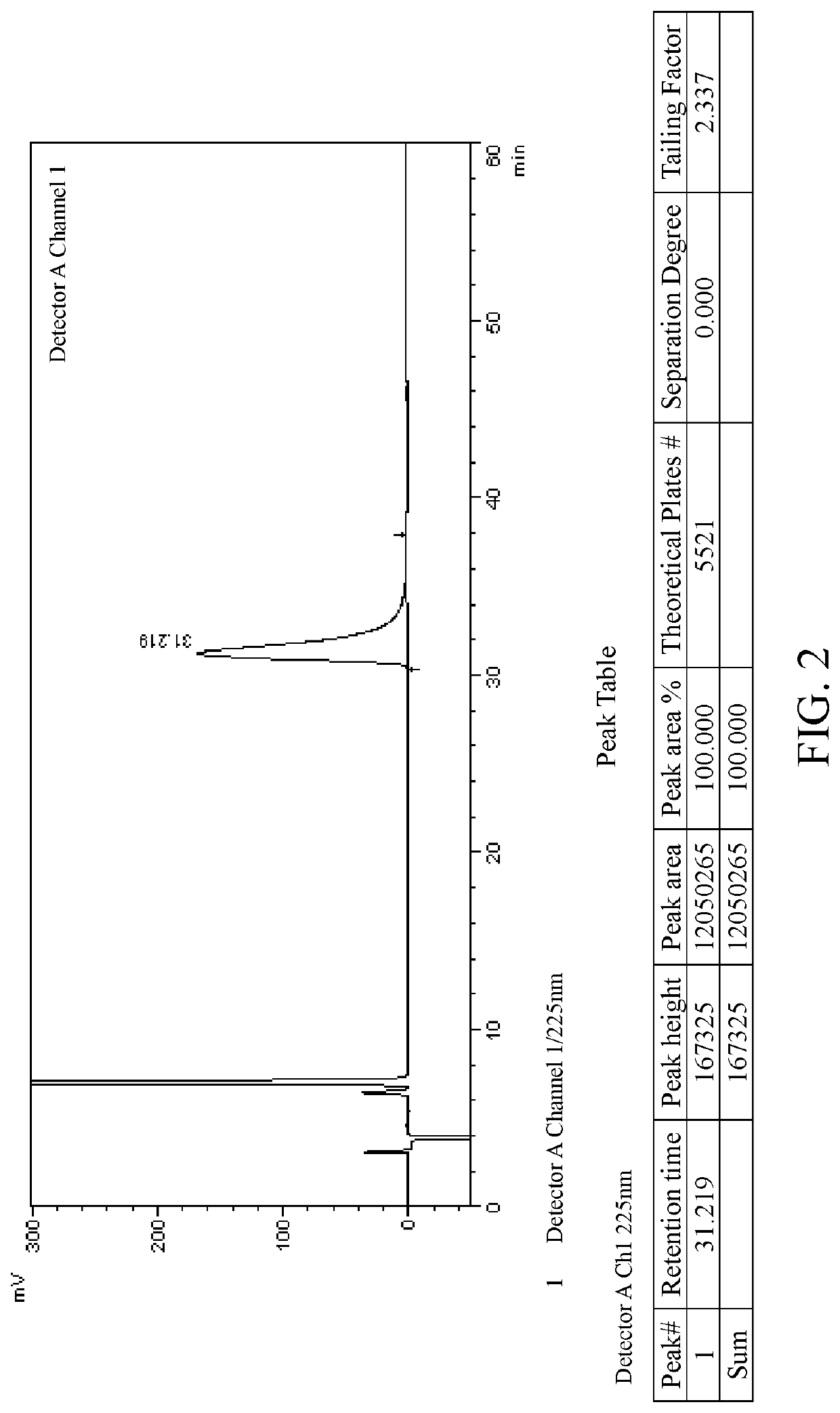

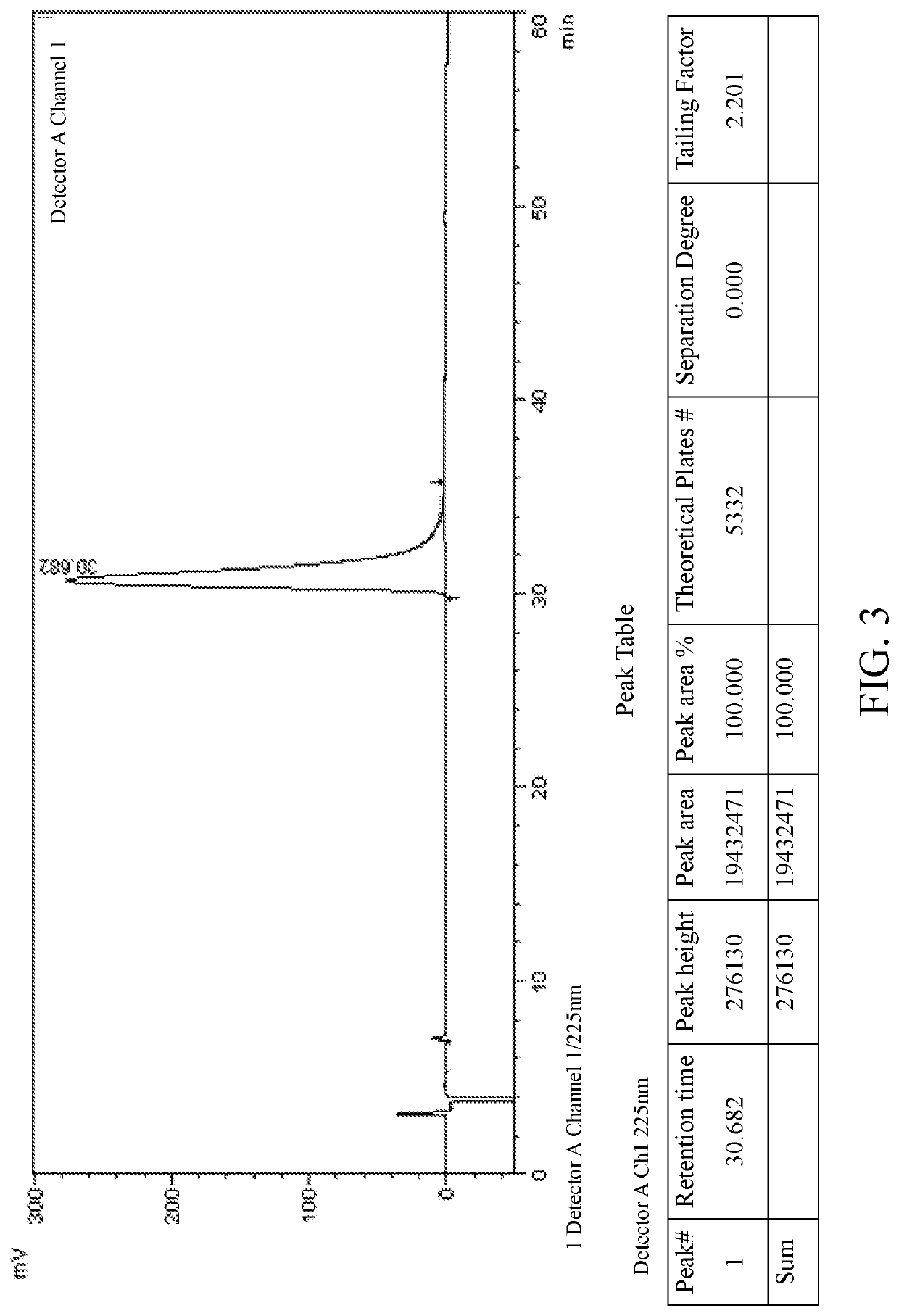

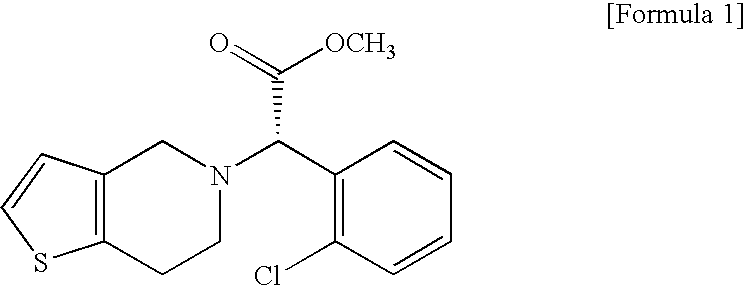

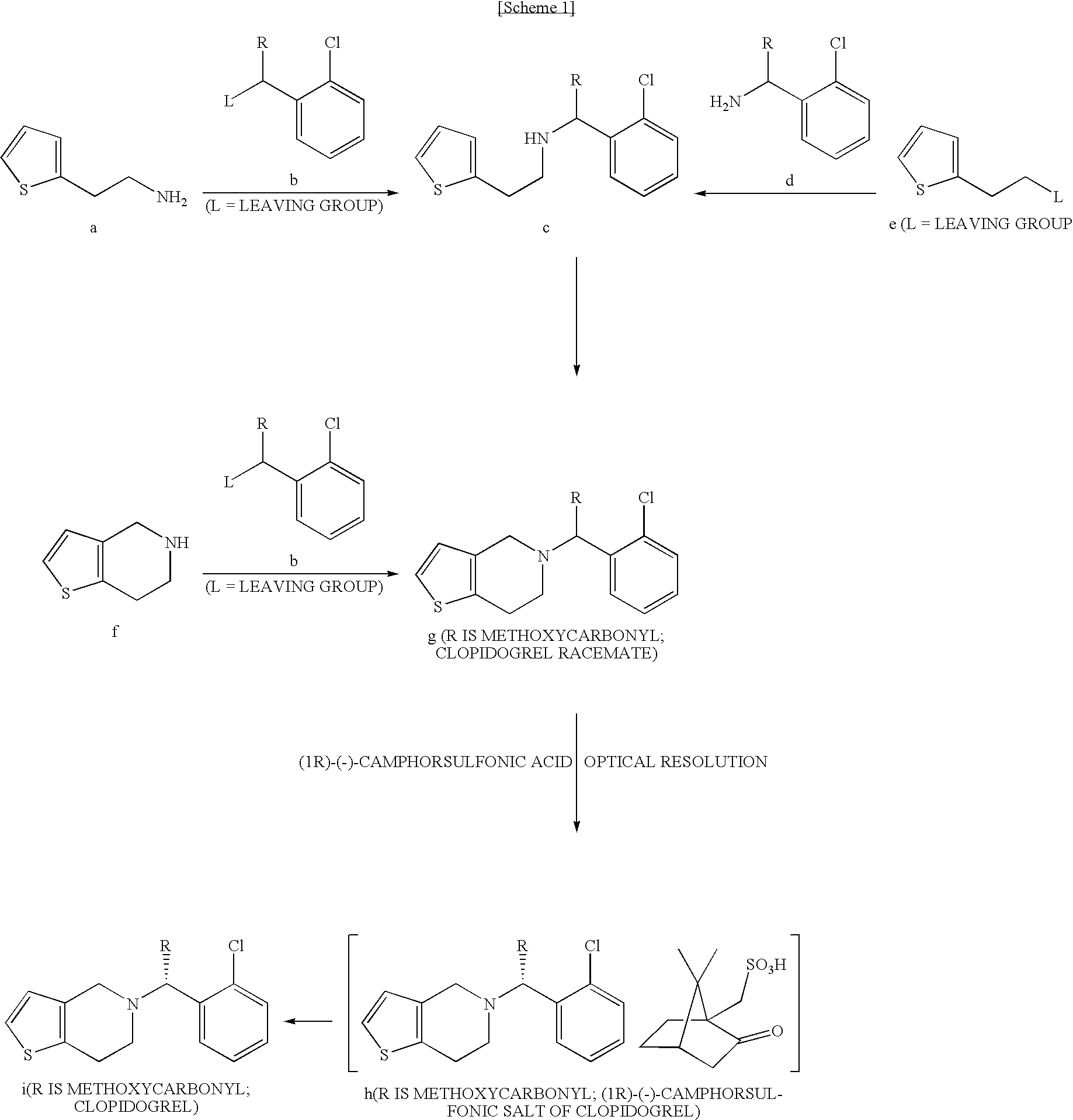

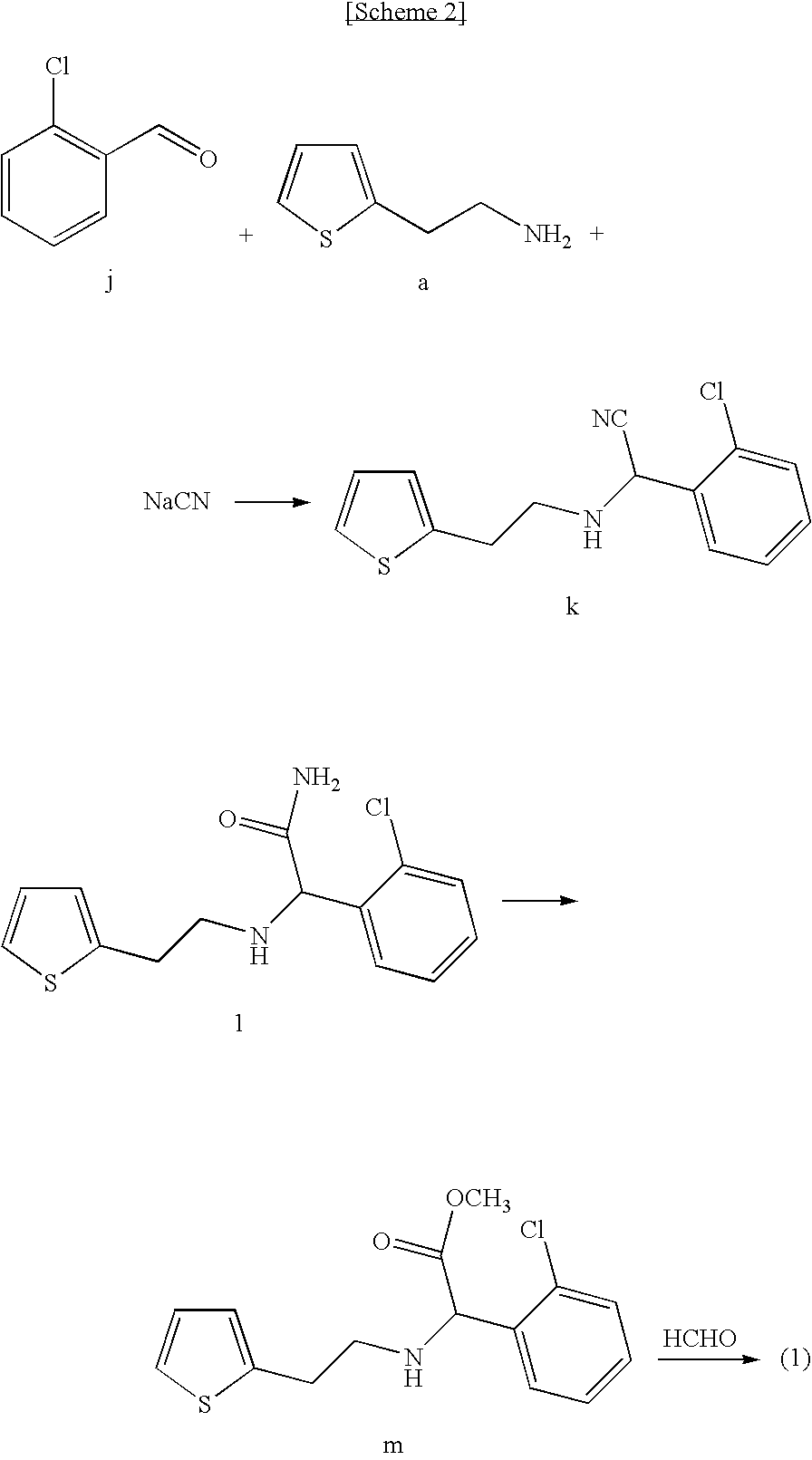

Process for the preparation of S-(+)-clopidogrel by optical resolution

InactiveCN101346386AEasy to manufactureHigh optical purityOrganic chemistryBlood disorderCinchonineCarboxylic acid

The present invention relates to a process for the preparation of S-(+)-clopidogrel by an optical resolution and, more particularly, to a process for the preparation of S-(+)-clopidogrel represented by the following formula 1 with high optical purity by converting a clopidogrel racemic carboxylic acid into a diastereomeric salt using a (+)-cinchonine for optical resolution, extracting an S-(+)-clopidogrel carboxylic acid from the diastereomeric salt using a suitable solvent under an acidic condition and then reacting the S-(+)-clopidogrel carboxylic acid with methanol.

Owner:SK CHEM CO LTD

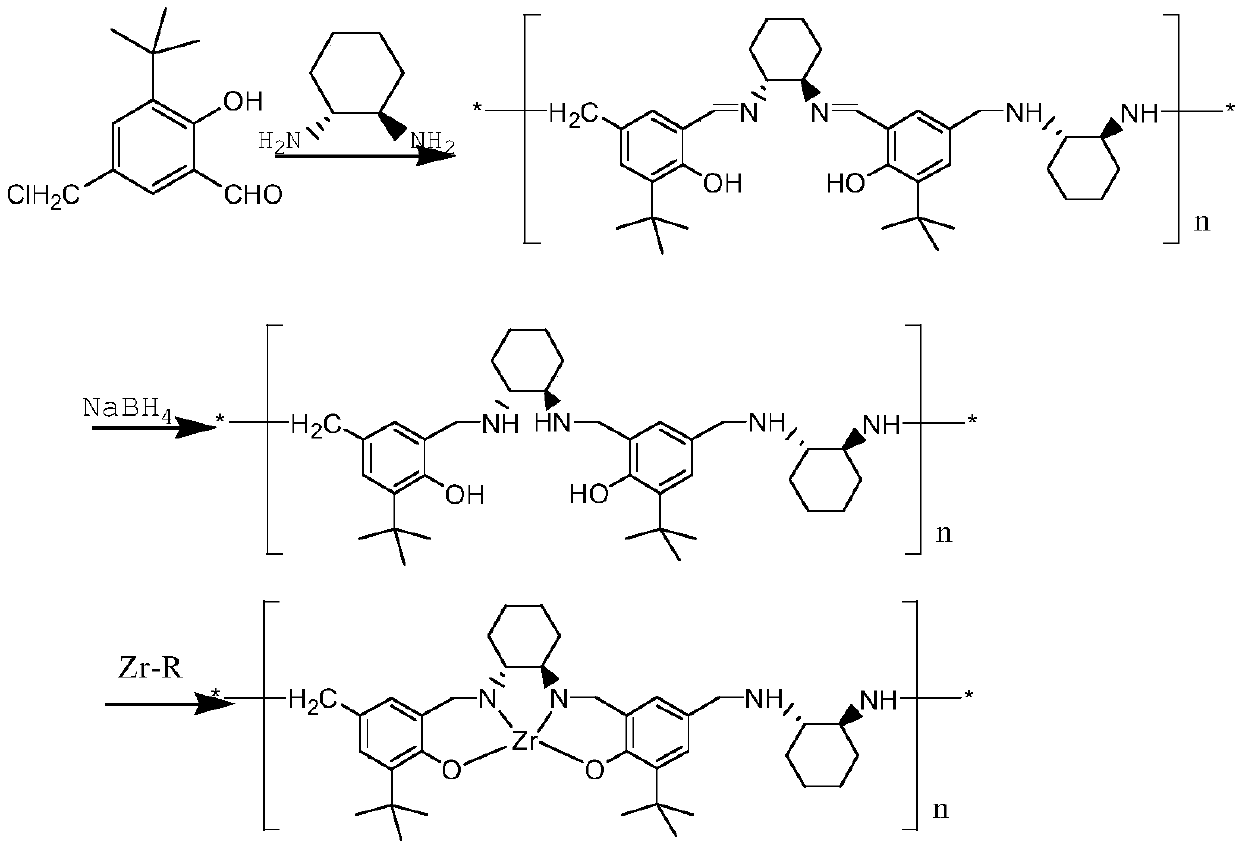

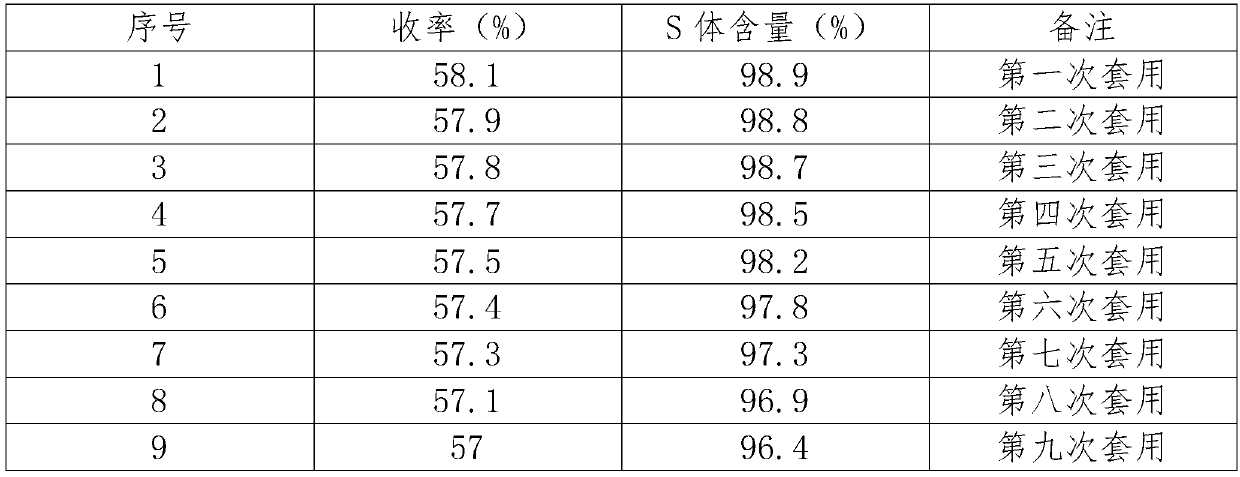

Preparation method of s-isomer indoxacarb

ActiveCN109701655AThe synthesis process is simpleReduce manufacturing costOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisSalicylaldehyde

The invention relates to the field of chemical synthesis, and particularly discloses a brand-new catalyst and a preparation method of s-isomer indoxacarb by using the catalyst, the catalyst is prepared from 3-tert-butyl-5-chloromethyl salicylaldehyde and cyclohexanediamine as raw materials, the catalyst is used for replacing original cinchonine and other cinchona alkaloid catalysts, and is appliedto asymmetric synthesis reaction of tert-butyl hydroperoxide and 5-chloro-2-methoxycarbonyl-1-indanone ester, the selectivity of the asymmetric synthesis process is greatly improved, and the contentof the s-isomer indoxacarb is increased from 75% to more than 98%, the recycling of the high-efficiency chiral catalyst is realized, the production cost is greatly reduced, the synthesis process of the catalyst is simple, the industrialization is facilitated, and a good foundation is laid for producing high-quality indoxacarb.

Owner:JINGBO AGROCHEM TECH CO LTD

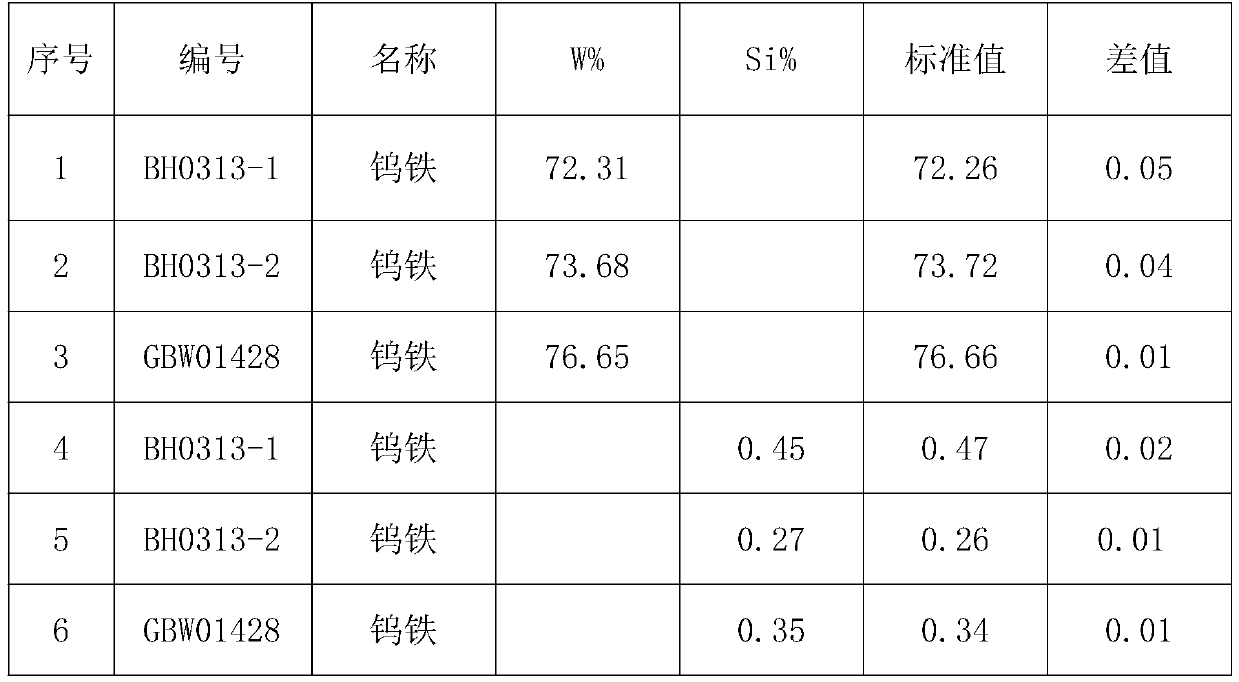

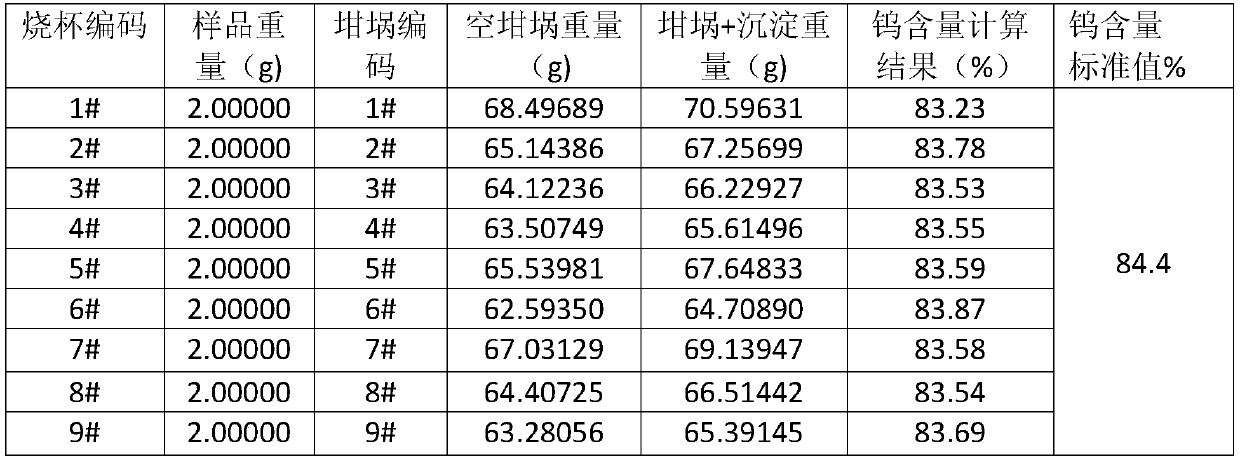

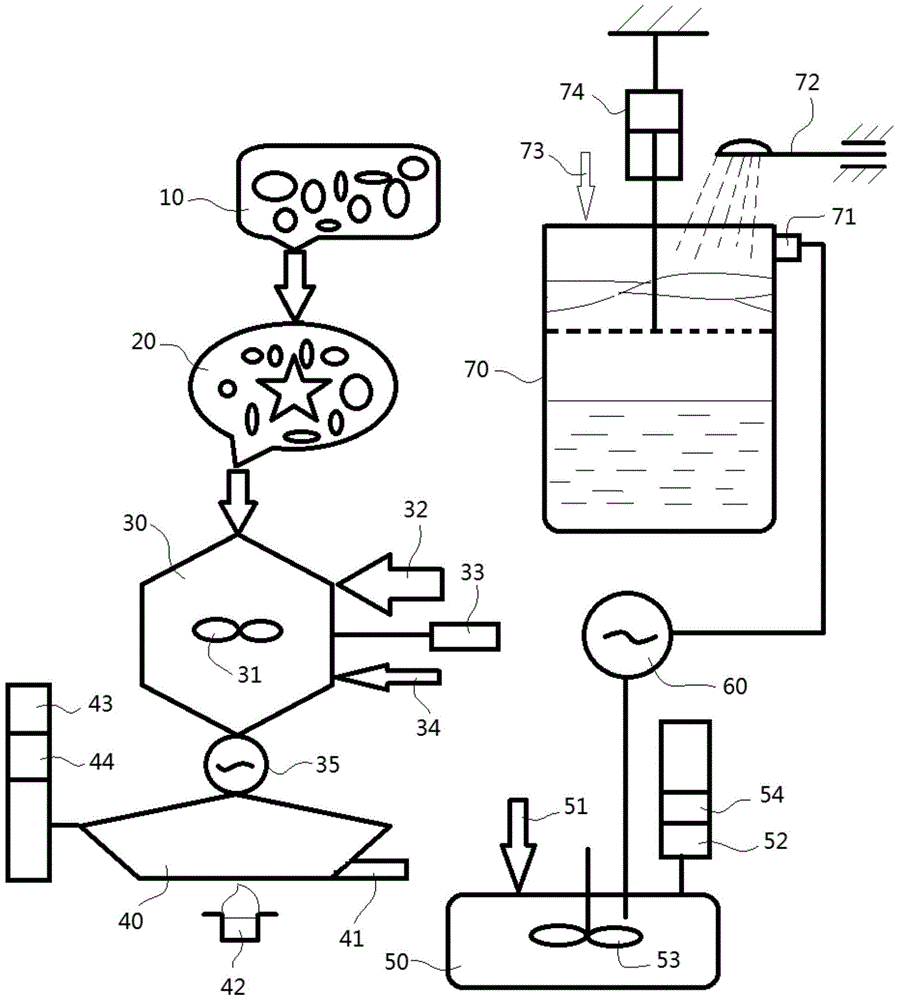

Combined determination method for contents of tungsten and silicon in ferrotungsten

PendingCN111307797AFast waySimple methodMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationCinchonineTungsten trioxide

The invention provides a combined determination method for contents of tungsten and silicon in ferrotungsten. The method comprises the following steps of preparing a reagent, preparing a cinchonine solution, and performing measurement and analysis. According to the method, the contents of tungsten and silicon in ferrotungsten can be jointly determined, and through test comparison, the method is rapid, convenient and high in precision and accuracy, is a time-saving and labor-saving test method, and can be suitable for production inspection. Sample sodium peroxide is melted and decomposed, hydrochloric acid acidification and nitric acid oxidation are carried out to generate an insoluble light yellow tungstic acid precipitate, and in order to enable the tungstic acid precipitate to be more completely added with an organic precipitant-cinchonine, the precipitate is filtered, washed, fired and subjected to impurity removal to obtain pure tungsten trioxide, and then the tungsten content is calculated, the contents of the two elements can be detected at the same time, the cost is reduced, the efficiency is improved, and the detection accuracy is high.

Owner:XINING SPECIAL STEEL +1

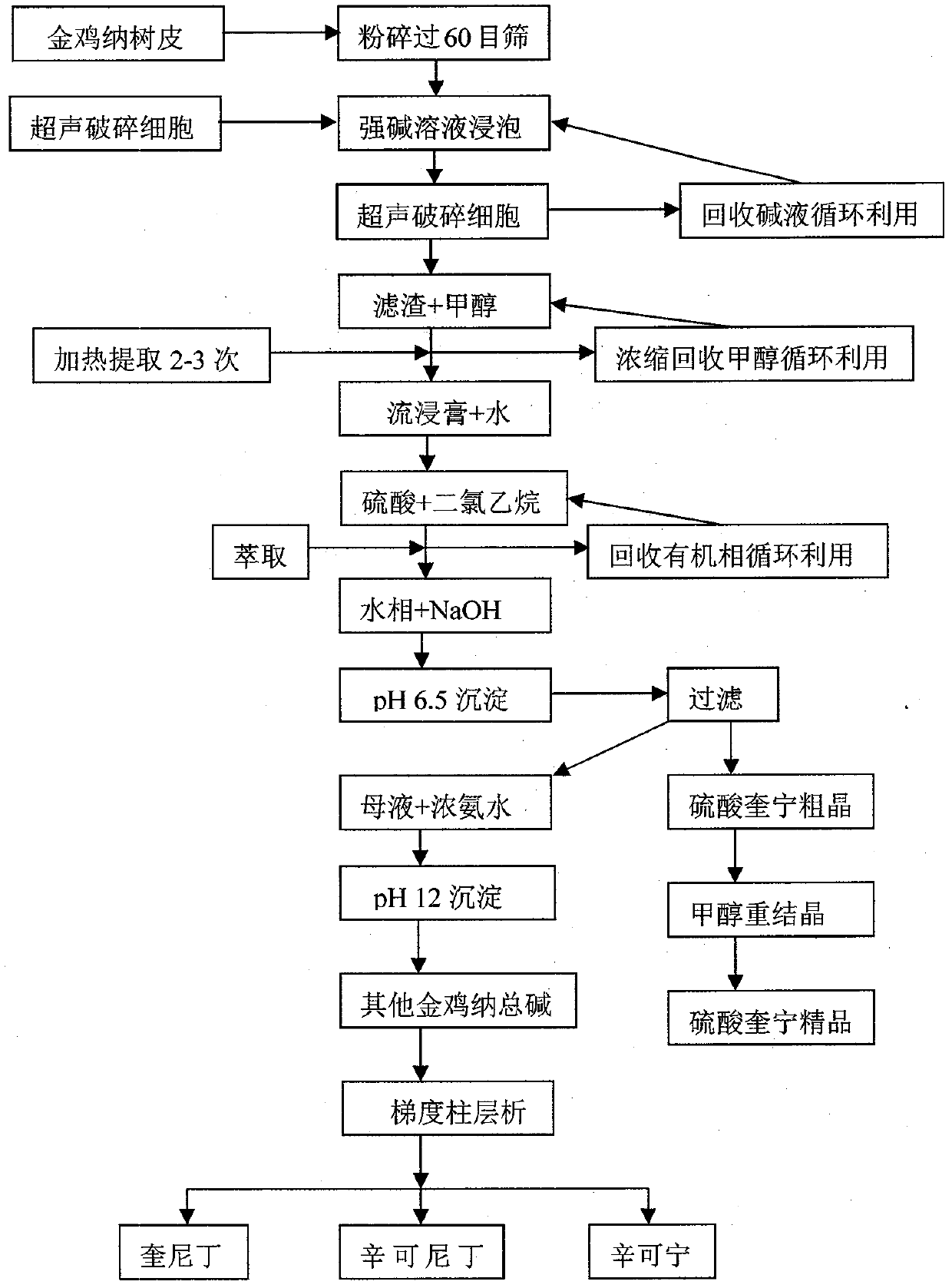

Method for preparing quinindium and cinchonine

InactiveCN102212064AAchieve purificationThe preparation method is economical, simple and convenientOrganic chemistryFiltrationPeruvian Bark

The invention discloses a method for preparing quinindium and cinchonine. The method comprises the following steps: separating out quinine from a total alkaloid of Peruvian bark through a sulfate precipitation method so as to obtain a filtrate containing other alkaloids; basifying the filtrate until the pH value is not less than 10, collecting the obtained precipitate and drying the precipitate so as to obtain a raw material A; dissolving the raw material A with an organic solvent, filtering, separating an indissoluble substance from the filtrate; dissolving the indissoluble substance with a proper amount of alcohol solvent, adding activated carbon for decoloring, and then carrying out filtration and crystallization so as to obtain the cinchonine; and concentrating the filtrate until the volume of filtrate is 1 / 5-1 / 10 of the original volume, standing until a solid is separated out, dissolving the solid with a proper amount of alcohol solvent, adding the activated carbon for decoloring, and then carrying out filtration and crystallization so as to obtain the quinindium. The method is economical, simple and convenient and is in favor of amplification production; and the yield is high.

Owner:JINAN UNIVERSITY

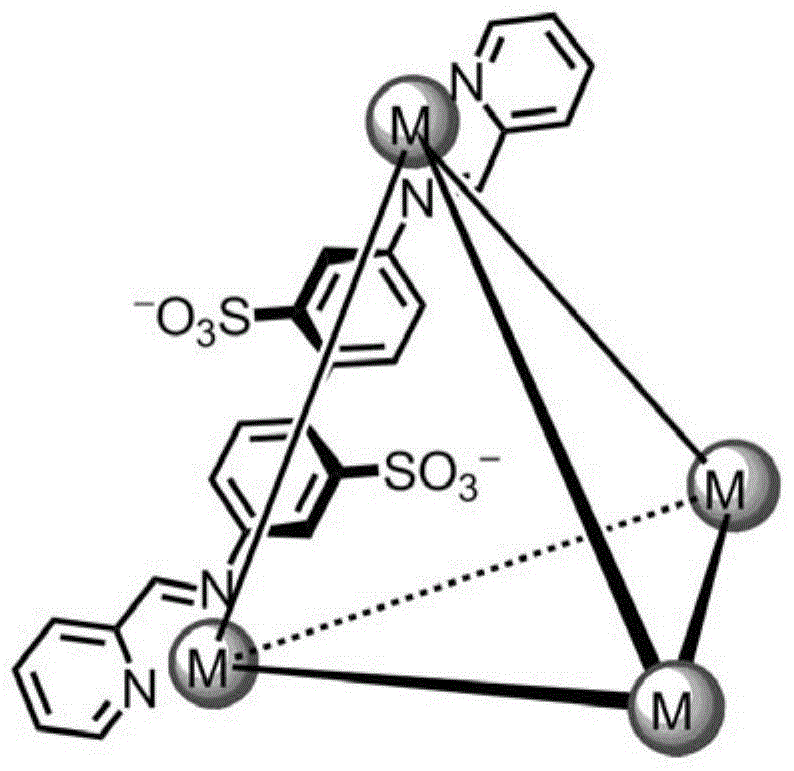

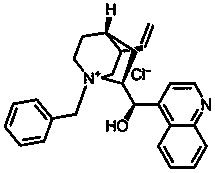

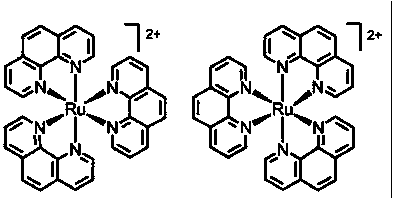

Resolving method of raceme polyhedral cage compound

InactiveCN103964987AHigh enantiopurityImprove efficiencyOptically-active compound separationOrganic racemisationEnantiomerRuthenium

The invention discloses a resolving method of a raceme polyhedral cage compound. The method comprises the following steps: (1) mixing a resolving agent and the raceme polyhedral cage compound based on the molar ratio of (1-4): 1, and adding methanol and / or water as a solvent to react for 1 to 24 hours under the temperature of 20 to 50 DEG C, wherein the solving agent is at least one of chiral binaphthol and derivates thereof, chiral quaternary ammonium salt and derivates thereof, cinchonine chloride and derivates thereof, chiral phenanthroline ruthenium complex cation and derivates thereof; and (2) precipitating to separate products produced in the reaction above, and removing the solving agent and the solvent to obtain a pair of enantiomers of the raceme polyhedral cage compound. The resolving method of the raceme polyhedral cage compound has the advantages that the operation method is simple, the resolving effect is good, and the efficiency is high.

Owner:XIAMEN UNIV

Industrialized production method for efficiently extracting, separating and purifying serial cinchona alkaloid from cinchona bark

InactiveCN102558169AGood extraction recoverySuitable for large-scale industrial productionOrganic chemistryAntipyreticFood additiveBULK ACTIVE INGREDIENT

The invention discloses a method for preparing serial cinchona alkaloid with effects of malaria resistance, arrhythmia resistance and the like by adopting cinchona bark as a raw material. The method utilizes advanced ultrasonic cell disruption and extraction, simple extraction separation and high-purity column purification process to generate quinine sulfate, quinidine, cinchonidine and cinchonine, of which the purities are all higher than 99.5%. Compared with the traditional method, the method has higher extraction recovery and environment-friendly and low-carbon process flow, and is better applicable to industrial mass production of active ingredients at the grade of GMP (Good Manufacturing Practice and food additives).

Owner:江苏斯威森生物医药工程研究中心有限公司

Method for synthesizing cinchona alkaloids microwave radiation non-solvent

InactiveCN101245063AQuick responseMild reaction conditionsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolvent freeDihydroquinine

The invention discloses a method of the solvent-free synthesis of cinchona alkaloid derivatives by adopting microwave radiation with the catalysis of a phase transfer catalyst. According to the method of the invention, 1, 4-dichloro-2, 3-naphthyridine, 3, 6-dichloropyridazine, 4, 6-dichloropyrimidines, 2, 5-diphenyl-4, 6-dichloropyrimidines or phthalic acid can react with quinine, hydroquinine, quinidine, dihydro quinidine, cinchonine or cinchonidine according to a mol ratio of 1:3 to 3:1 to obtain the cinchona alkaloid derivatives. Under the action of microwave, the synthetic process of the cinchona alkaloid derivatives can become simple and safe in operation, short in reaction time, and mild in reaction condition; more particularly, toxic organic solvents such as methylbenzene and DMF with a high boiling point, etc. are not adopted in the course of the reaction, thus being in line with the megatrend of green chemistry, furthermore, monosubstituted products and disubstituted products can be obtained with high yield by the control of reaction time and power.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

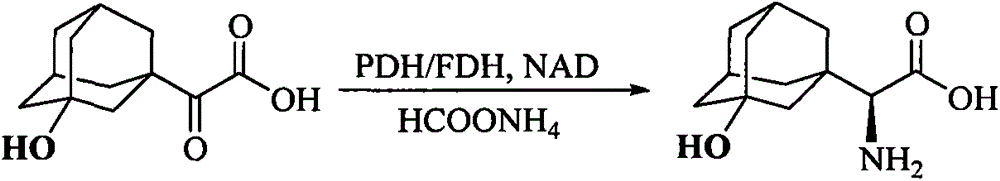

(s)-3-hydroxyadamantylglycine preparation method

InactiveCN104892443AHigh selectivityMild reaction conditionsOrganic compound preparationAmino-carboxyl compound preparationAcetic acidAqueous sodium hydroxide

Owner:JIAXING UNIV

Tungsten-contained material treating method

InactiveCN104843791AEfficient decompositionTungsten content in small outer slagTungsten compoundsAlkaline earth metalSlag

A tungsten-contained material treating method aims at enabling a specific value of the 0.5 order power of mass percent of tungsten trioxide to the mass percent of silicon dioxide in raw materials to be smaller or equal to 0.5-0.8 by ore blending; the method comprises the following steps: placing tungsten-contained material solid in crushing equipment for crushing to ideal particle size; then adding a decomposer, namely, sodium hydroxide or a sodium hydroxide solution, stirring, adding a small quantity of water while adding the decomposer, and controlling a mixing volume to be 0.9-1.2 times that of the tungsten-contained material; controlling decomposition temperature to be 120-200 DEG C, preserving the temperature for 2-5hours after the decomposition temperature is achieved; controlling solution temperature to be 50-100 DEG C after unloading, dropwise adding a cinchonine solution, washing the solution of pressure filter residue till no white precipitate exists, as a washing end point, unloading a pressure filter plate and roughing slag. According to the method, the waste of impurity silicon dioxide in ore is made profitable, after achieving a grade during ore blending, the silicon dioxide becomes an inhibitor of alkaline earth metal, and the tungsten content of decomposed slag is smaller than 1%.

Owner:江钨世泰科钨品有限公司

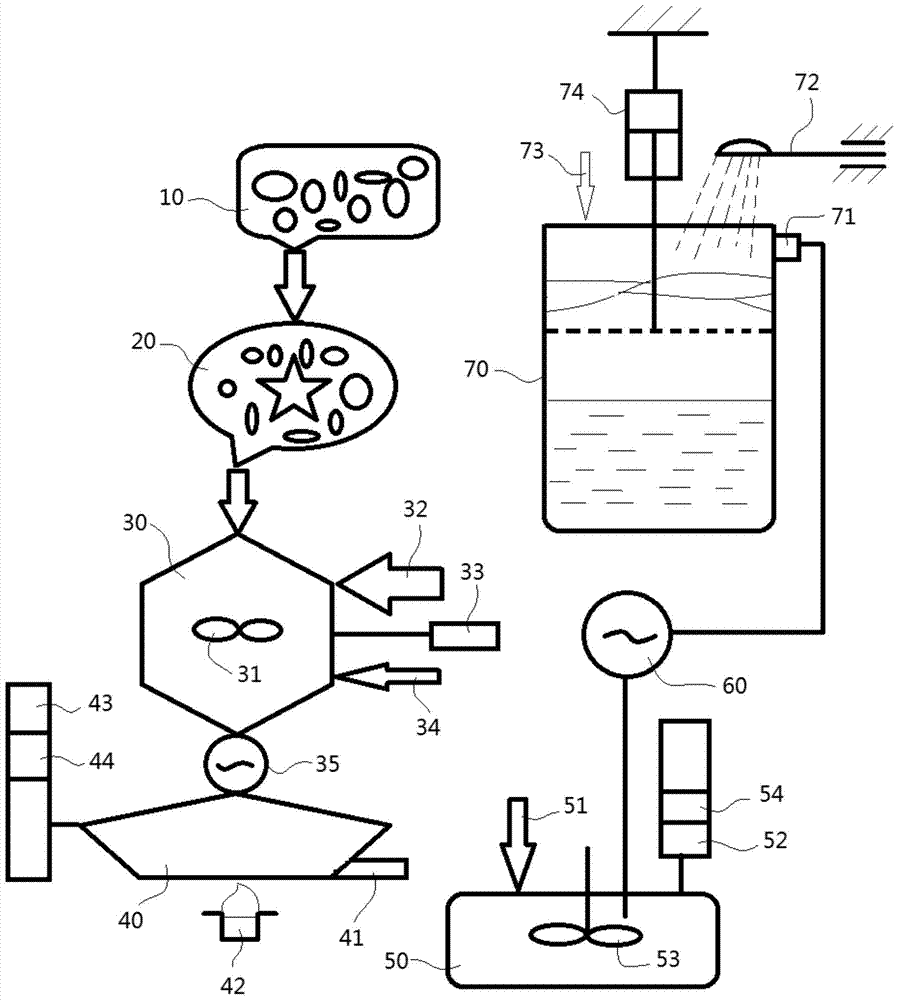

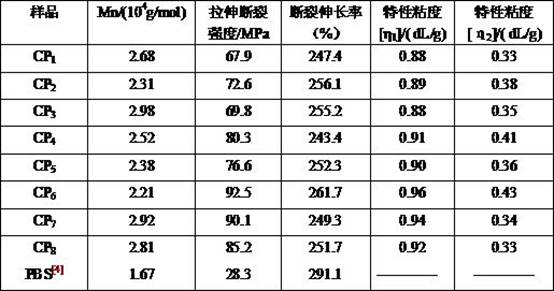

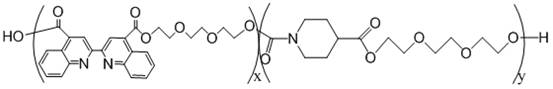

Degradable copolyester based on triethylene glycol, preparation and application

The invention discloses a preparation method and application of degradable copolyester based on triethylene glycol, and belongs to the field of polyester synthesis. The method comprises the following steps: carrying out esterification reaction on monomers piperidine-1,4 dicarboxylic acid, 2,2'-bicinchoninic acid, triethylene glycol and a catalyst to obtain an esterification product; heating the esterification product for condensation polymerization to obtain a crude product of a condensation polymerization product; and finally, conducting extracting by a solvent, conducting precipitating by a precipitator, and conducting filtering and drying to obtain a target product. The weight-average molecular weight of the polyester obtained by the method disclosed by the invention is 20000-30000 g / mol. The copolyester synthesized by the method disclosed by the invention is relatively good in mechanical property and flexibility, easy to degrade by the environment and harmless to the environment. The degradable copolyester based on triethylene glycol prepared by the invention is used for preparing an antibacterial plastic matrix.

Owner:WUHAN UNIV OF SCI & TECH

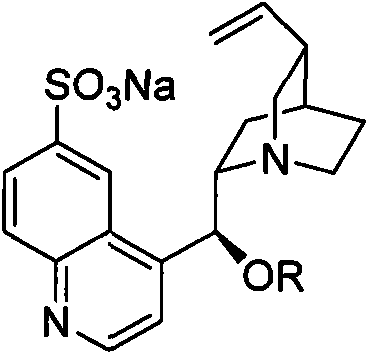

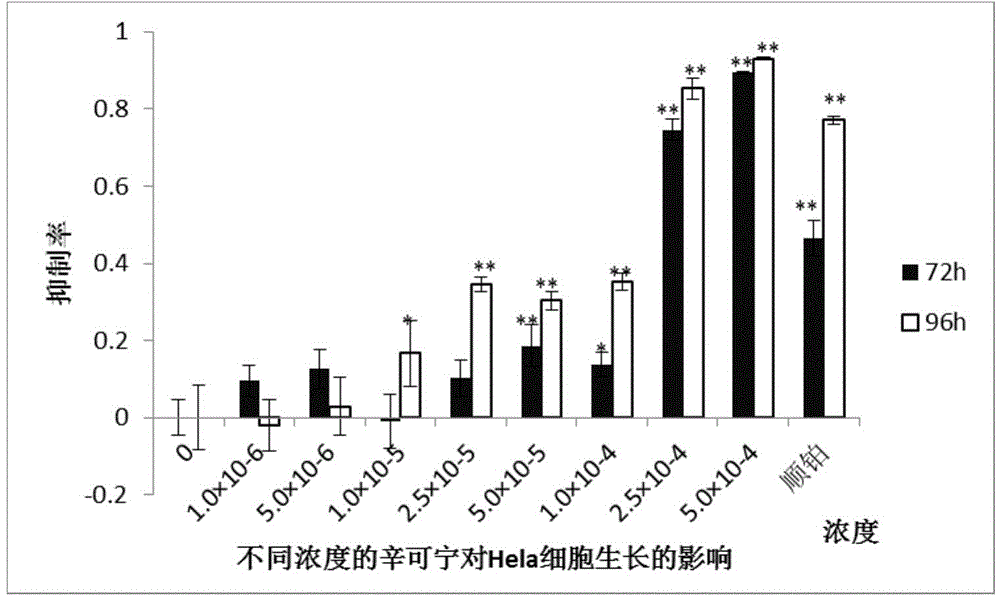

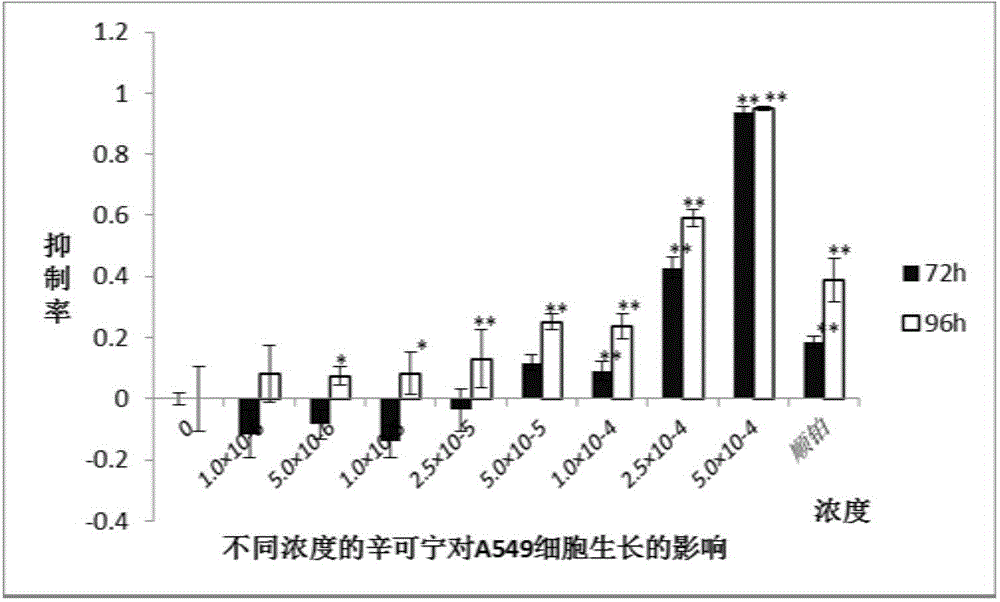

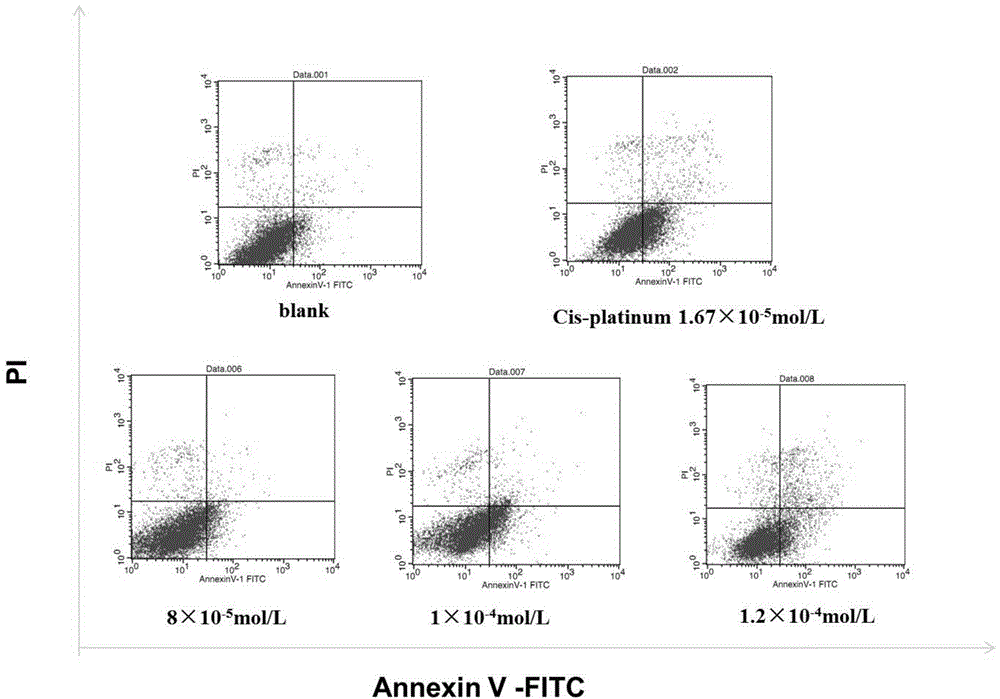

Use of cinchonine in preparation of anti-tumor drugs

InactiveCN105796558ALittle side effectsSmall side effectsAntineoplastic agentsHeterocyclic compound active ingredientsSide effectCinchonine

The invention discloses a use of cinchonine in preparation of anti-tumor drugs. Cinchonine is found out to have a role in inhibiting growth of tumor cells during screening of a large number of anti-tumor drugs. When cinchonine is clinically applied in treatment of malaria, generated side effects are smaller than side effects generated by conventional anti-tumor drugs, and cinchonine is the new anti-tumor drug having small side effects.

Owner:TIANJIN UNIV

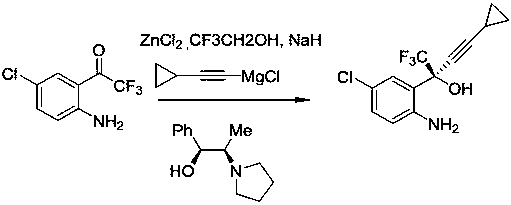

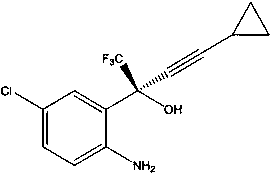

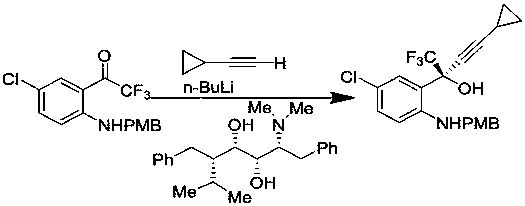

Method for asymmetric synthesis of anti-Aids drug, namely efavirenz key intermediate

InactiveCN110746312AHigh yieldHigh ee valueOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPharmacologyEfavirenz

The invention discloses a method for asymmetric synthesis of an anti-Aids drug, namely an efavirenz key intermediate. The method comprises the following steps that in an organic solvent, fluoride, anorganic ligand (9S)-6'-methoxy-deoxidized cinchonine-9-ol and cyclopropyl acetylene are evenly stirred, an organic zinc solution is slowly added at the temperature of 15-25 DEG C, after constant-temperature stirring is conducted for 3-5 hours, tetraisopropyl titanate is added, stirring is continued to be conducted for 2-3 hours, then the temperature is decreased to minus 20 DEG C to 0 DEG C, 5-chloro-2-amino-trifluorobenzophenone is added, a mixture is stirred at the temperature of minus 20 DEG C to 0 DEG C for 5-12 hours, after a reaction is completed, a proton source is added for a quenchingreaction, then a certain amount of activated carbon is added, a mixture is stirred for 0.5 hour and filtered, an organic phase and a water phase are separated in an extraction mode, the organic phaseis washed, dried and subjected to vacuum concentration, and after purification, the efavirenz key intermediate is obtained. The technological process is short, the technological condition is mild, operation is easy, environmental protection is achieved, the cost is low, and the method is suitable for industrial production.

Owner:湖北随州双星生物科技有限公司 +1

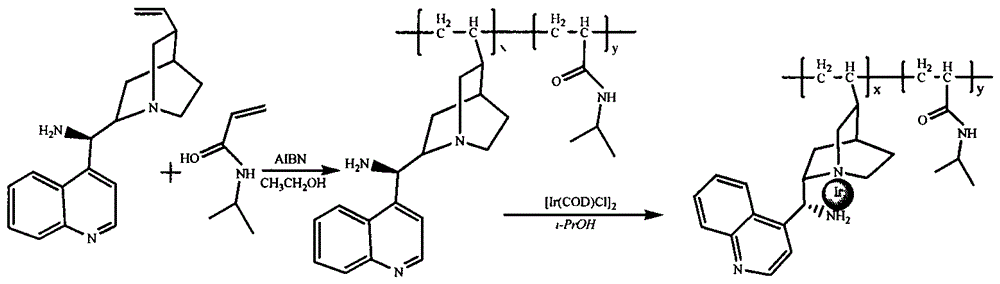

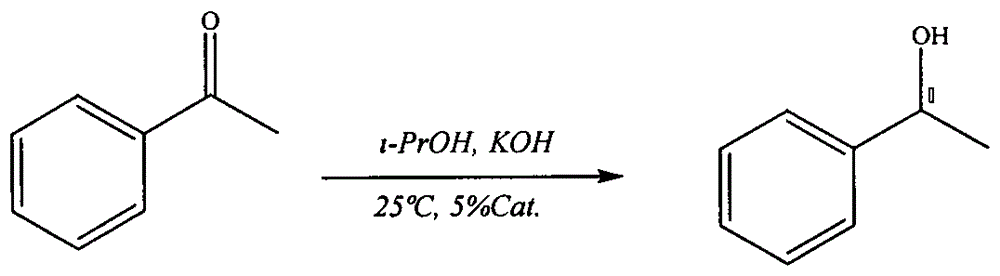

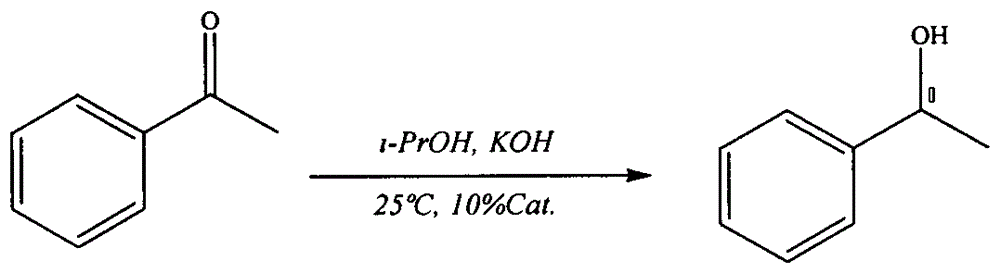

Preparation method of thermal-sensitive type catalyst used for asymmetric hydrogen transfer reaction

InactiveCN105884968ASimple manufacturing methodOvercome recycling difficultiesOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCinchonineHeat sensitive

The invention relates to a preparation method of a thermal-sensitive type catalyst used for an asymmetric hydrogen transfer reaction. The method comprises the steps that azodiisobutyronitrile serves as an initiator, a thermal-sensitive type polymer is obtained through 9-amine cinchonine and N-isopropylmethacylamide, complexation is conducted on the polymer and an iridium compound, and the catalyst is obtained. The prepared catalyst can be used for an acetophenone asymmetric hydrogen transfer reaction, and the high catalytic activity and enantioselectivity are achieved. The catalyst has the thermal-sensitive characteristic, after the reaction is finished, separation and recycling are easy, and reutilization is achieved. According to the preparation method of the thermal-sensitive type catalyst used for the asymmetric hydrogen transfer reaction, an effective way is provided for separation and recycling of a metal organic complex catalyst, and a wide application prospect is achieved.

Owner:NANKAI UNIV

Resolution method for axis chiral enantiomers of lesinurad

ActiveUS20210053928A1Easy to separateConveniently recovered and reusedOrganic active ingredientsSkeletal disorderLesinuradEnantiomer

A resolution method of axial chiral enantiomers of lesinurad (2-(5-bromo-4-(4-cyclopropylnaphthalen-1-yl)-4H-1,2,4-triazol-3-ylthio)acetic acid) adopts inexpensive and readily available quinoline natural products and derivatives thereof, such as quinine, cinchonine, quinidine or cinconidine as resolving agents to react with lesinurad racemate in an organic solvent to form a salt, and the salt is dissociated by acidification so as to obtain optically pure (R)- or (S)-2-(5-bromo-4-(4-cyclopropylnaphthalen-1-yl)-4H-1,2,4-triazol-3-ylthio)acetic acid. The method can give axial chiral enantiomer of lesinurad in R configuration with a chiral purity ee of up to 100% and a total yield of 90% or more. The obtained axial chiral enantiomer of lesinurad in S configuration can reach a chiral purity ee of up to 99.9% and a total yield of 80% or more.

Owner:CHINA RESOURCES SAIKE PHARMA

Process for the Preparation of S-(+)-Clopidogrel by Optical Resolution

InactiveUS20090275755A1High purityHigh optical purityOrganic chemistryBlood disorderCinchonineCarboxylic acid

The present invention relates to a process for the preparation of S-(+)-clopidogrel by an optical resolution and, more particularly, to a process for the preparation of S-(+)-clopidogrel represented by the following formula 1 with high optical purity by converting a clopidogrel racemic carboxylic acid into a diastereomeric salt using a (+)-cinchonine for optical resolution, extracting an S-(+)-clopidogrel carboxylic acid from the diastereomeric salt using a suitable solvent under an acidic condition and then reacting the S-(+)-clopidogrel carboxylic acid with methanol.

Owner:SK CHEM CO LTD

Method for determining tungsten content in tungsten-containing polyethylene composite shielding material

InactiveCN110646319AImprove detection accuracyGood repeatabilityWeighing by removing componentMuffle furnaceSodium hydroxide

The invention provides a method for determining tungsten content in a tungsten-containing polyethylene composite shielding material. The method comprises the steps of: 1, weighing a certain amount ofsample, putting the sample into a quartz crucible, slowly heating and firing the sample in a muffle furnace, and taking the sample out after cooling; 2, transferring the sample into a beaker, adding asodium hydroxide solution into the beaker, heating the beaker until the sample is dissolved, cooling the heated sample, and filtering the sample with medium-speed quantitative filter paper; 3, addinga hydrochloric acid into the filtrate, carrying out water-bath heating and concentration, adding deionized water into the product, adding a cinchonine solution into the mixture after slightly boiling, fully stirring the mixture, and carrying out heat preservation on the mixture; 4, filtering the mixture with dense quantitative filter paper, washing precipitate with cinchonine lotion for multipletimes, transferring the precipitate and the filter paper into a fired platinum crucible, and placing the precipitate and the filter paper in a muffle furnace and firing the same; step 5, taking out the fired precipitate, the filter paper and the platinum crucible together, cooling them to room temperature, adding an hydrofluoric acid and a plurality of drops of concentrated sulfuric acid into theplatinum crucible, carefully heating and evaporating the liquid, firing the platinum crucible, firing the platinum crucible again and then cooling the product to room temperature, and weighing the product until the weight is constant; and step 6, calculating to obtain the tungsten content in tungsten-boron polyethylene according to a predetermined formula. The implemented method is high in detection precision and high in repeatability.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

A method of processing tungsten-containing materials

InactiveCN104843791BEfficient decompositionTungsten content in small outer slagTungsten compoundsAlkaline earth metalDecomposition

Owner:江钨世泰科钨品有限公司

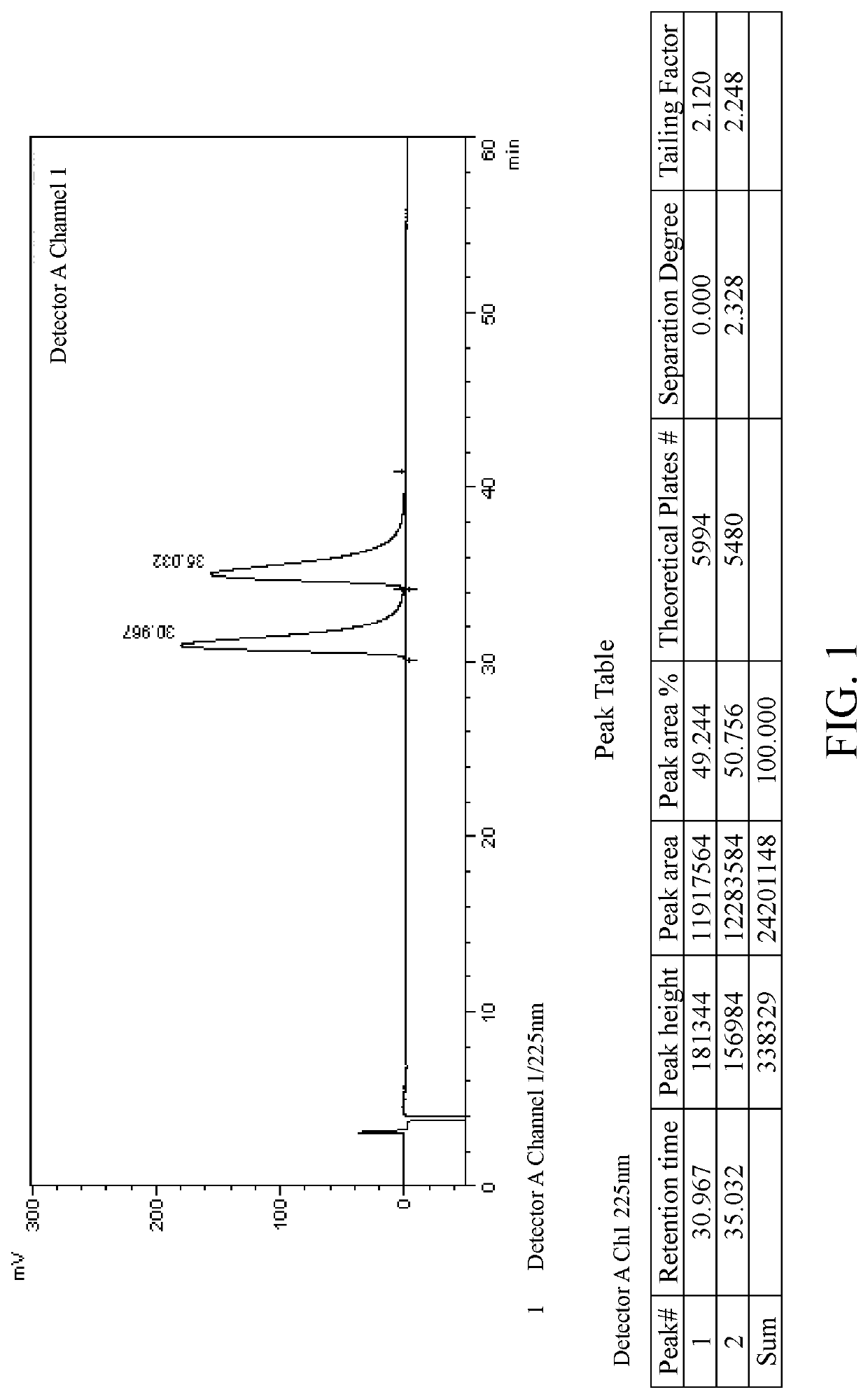

Synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule

ActiveCN109970697BEconomical large-scale preparationGood for mass manufacturingOrganic chemistry methodsPropanoic acidPtru catalyst

The invention relates to a synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule. Using phenylpropionic acid as the starting material, react with monoethylmagnesium malonate to obtain β-ketoester, and then construct the spirolide structure through acid-catalyzed series Friedel-Crafts reaction in one pot, and then through trifluoroform The sulfonate ester activates the phenolic hydroxyl group, and finally removes the occupying atom and the sulfonate group by palladium-carbon hydrogenation to complete the synthesis of the chiral spiro[chroman-4,1'-dihydroindene] molecule. The racemate was optically resolved under the action of N-benzylhalogenated cinchonidine. The synthesis method overcomes the problems of poor atom economy, many synthetic wastes, and low practical value of the original method, and realizes simple and economical large-scale preparation of the target molecule; the separation method is green and efficient, and the separation reagent, solvent It can be used multiple times; the product molecule and synthesis method have important application value and potential in catalyst skeleton design and natural product drug synthesis.

Owner:NANKAI UNIV

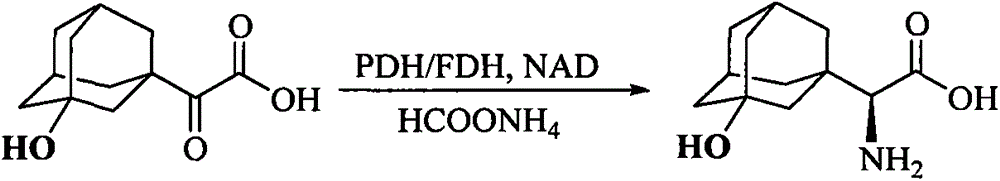

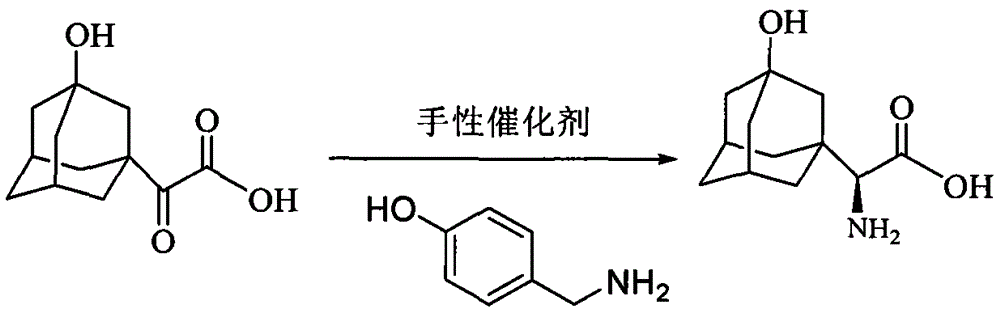

The preparation method of (s)-3-hydroxyadamantane glycine

InactiveCN104892443BHigh selectivityMild reaction conditionsOrganic compound preparationAmino-carboxyl compound preparationGlycineEnantiomer

The invention relates to a (s)-3-hydroxyadamantylglycine preparation method, which takes 2-(3-hydroxy-1-adamantane)-2-glyoxalic acid as a raw material, in a sodium hydroxide aqueous solution, under effects of a chiral catalyst and p-hydroxybenzylamine, (s)-3-hydroxyadamantylglycine can be generated, wherein the chiral catalyst is a quinoline alkaloid cinchonine derivative. The preparation method has the characteristics of mild reaction condition, high product yield, high purity and high enantiomer selectivity, has the advantages of short route, simple operation, no pollution and easy industrial production, and is the economic and simple method.

Owner:JIAXING UNIV

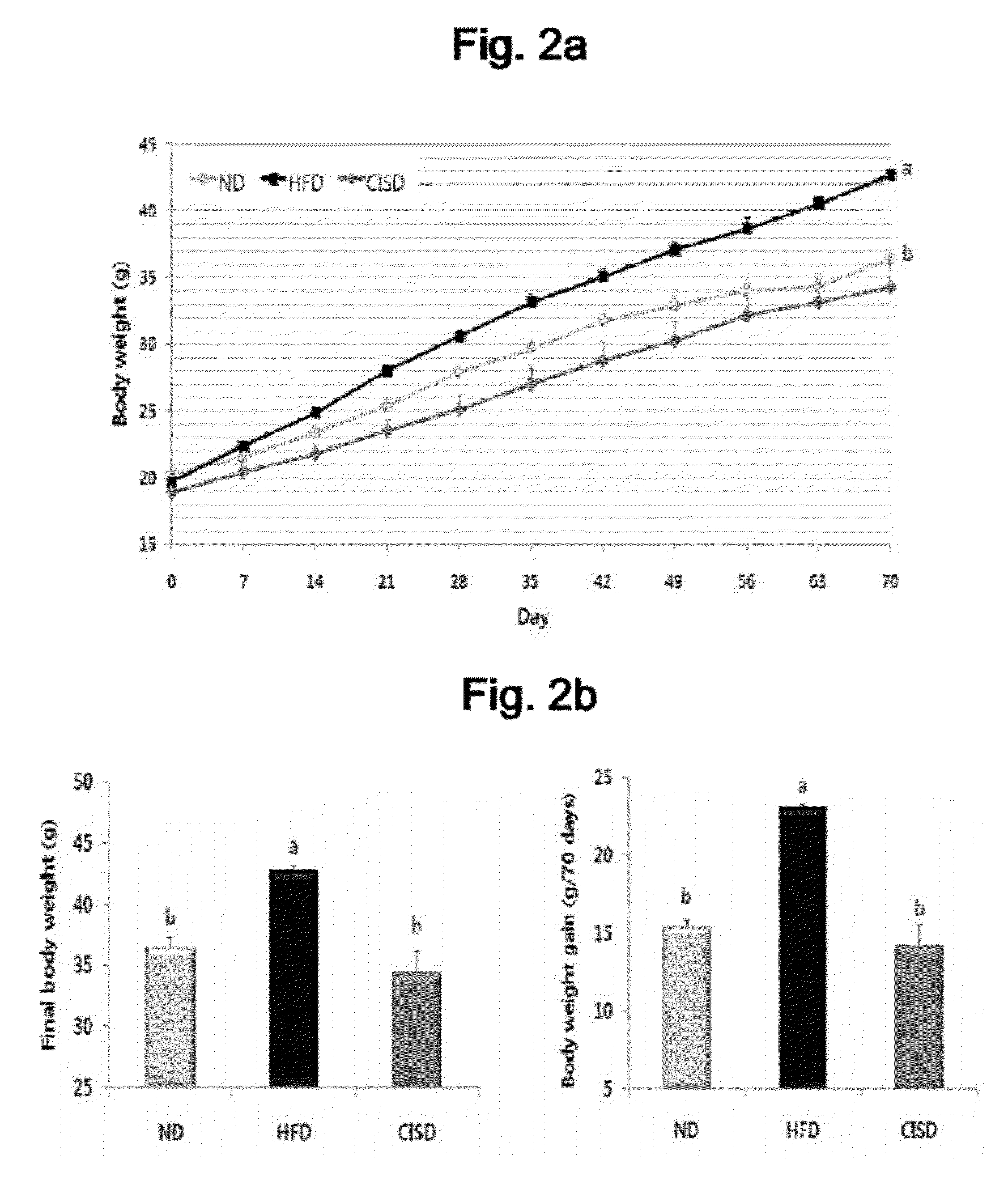

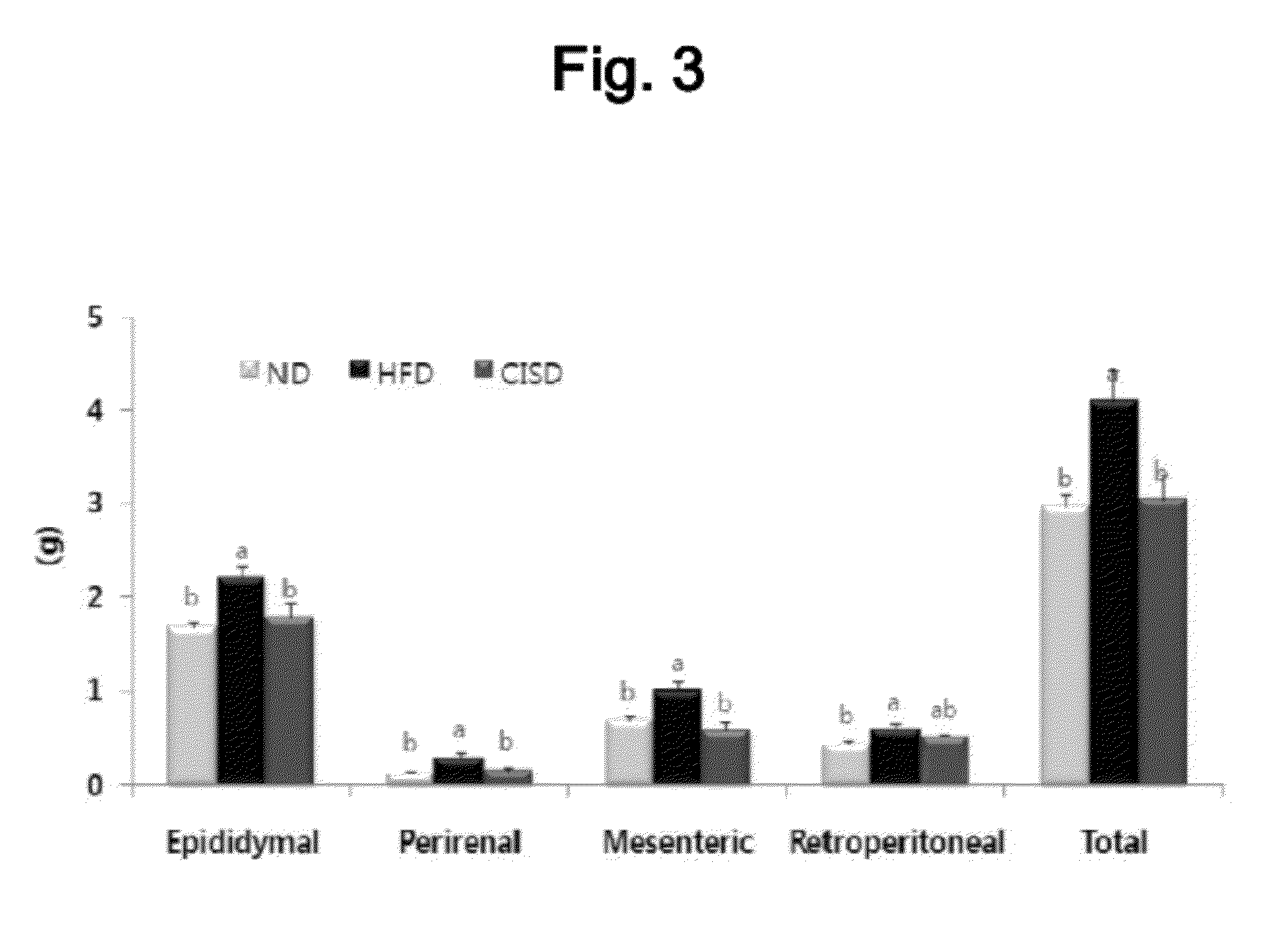

Composition containing cinchonine as an active ingredient for preventing and treating obesity, dyslipidemia, fatty liver, or insulin resistance syndrome

ActiveUS20120322822A1Decrease in fasting glucose level levelDecrease in level blood insulin levelBiocideMetabolism disorderTG - TriglycerideTriglyceride level

The present invention relates to a composition for preventing or treating obesity, dyslipidemia, fatty liver or insulin resistance syndrome, comprising cinchonine as an active ingredient. The composition of the present invention comprising cinchonine as an active ingredient contributes to not only inhibition of adipocyte differentiation but also reductions of body weight, visceral fat, total cholesterol level, plasma triglyceride level and liver tissue triglyceride level, thereby exerting prevention or treatment efficacies of obesity, hyperlipidemia or fatty liver. In addition, the composition of the present invention induces significant decrease in fasting glucose level and blood insulin level to improve type 2 diabetes, insulin resistance and related metabolic diseases.

Owner:YONSEI UNIV TECH HLDG

Method for preparing quinindium and cinchonine

InactiveCN102212064BAchieve purificationThe preparation method is economical, simple and convenientOrganic chemistryFiltrationPeruvian Bark

The invention discloses a method for preparing quinindium and cinchonine. The method comprises the following steps: separating out quinine from a total alkaloid of Peruvian bark through a sulfate precipitation method so as to obtain a filtrate containing other alkaloids; basifying the filtrate until the pH value is not less than 10, collecting the obtained precipitate and drying the precipitate so as to obtain a raw material A; dissolving the raw material A with an organic solvent, filtering, separating an indissoluble substance from the filtrate; dissolving the indissoluble substance with a proper amount of alcohol solvent, adding activated carbon for decoloring, and then carrying out filtration and crystallization so as to obtain the cinchonine; and concentrating the filtrate until the volume of filtrate is 1 / 5-1 / 10 of the original volume, standing until a solid is separated out, dissolving the solid with a proper amount of alcohol solvent, adding the activated carbon for decoloring, and then carrying out filtration and crystallization so as to obtain the quinindium. The method is economical, simple and convenient and is in favor of amplification production; and the yield is high.

Owner:JINAN UNIVERSITY

Process for the preparation of S-(+)-clopidogrel by optical resolution

The present invention relates to a process for the preparation of S-(+)-clopidogrel by an optical resolution and, more particularly, to a process for the preparation of S-(+)-clopidogrel represented by the following formula 1 with high optical purity by converting a clopidogrel racemic carboxylic acid into a diastereomeric salt using a (+)-cinchonine for optical resolution, extracting an S-(+)-clopidogrel carboxylic acid from the diastereomeric salt using a suitable solvent under an acidic condition and then reacting the S-(+)-clopidogrel carboxylic acid with methanol.

Owner:SK CHEM CO LTD

9S-acyloxy cinchonine derivatives, preparation method and application thereof, and plant-derived insecticide

ActiveCN110759905AHas insecticidal activityConfiguration has little effectBiocideOrganic chemistryCinchoninePerylene derivatives

The invention belongs to the technical field of heterocyclic compounds, particularly relates to 9S-acyloxy cinchonine derivatives and a preparation method and application thereof, and further relatesto a plant-derived insecticide. A structural formula of the 9S-acyloxy cinchonine derivatives is as follows: (please see the specification for the formula), wherein R is selected from any one of an alkyl, a phenyl alkylene, a naphthyl alkylene, a phenyl and a substituted phenyl; the number of carbon atoms in the alkyl is 1 to 5; the number of carbon atoms of an alkylene in each of the phenyl alkylene and the naphthyl alkylene is 1 to 4; and a substituted group in the substituted phenyl is one or more of a halogen, a nitryl, an alkoxy, and an alkyl with 1 to 4 carbon atoms, and the number of carbon atoms in the alkoxy is 1 to 3. The 9S-acyloxy cinchonine derivatives have good insecticidal activity, the insecticidal effects of most of derivatives exceed commercialized plant-derived insecticide, namely toosendanin, the 9S-acyloxy cinchonine derivatives have good application prospects, and a new direction is provided for development of plant-derived pesticides.

Owner:HENAN UNIV OF SCI & TECH

A method for resolution of racemic polyhedral cage compound

InactiveCN103964987BHigh enantiopurityImprove efficiencyOptically-active compound separationOrganic racemisationEnantiomerPhenanthroline

The invention discloses a resolving method of a raceme polyhedral cage compound. The method comprises the following steps: (1) mixing a resolving agent and the raceme polyhedral cage compound based on the molar ratio of (1-4): 1, and adding methanol and / or water as a solvent to react for 1 to 24 hours under the temperature of 20 to 50 DEG C, wherein the solving agent is at least one of chiral binaphthol and derivates thereof, chiral quaternary ammonium salt and derivates thereof, cinchonine chloride and derivates thereof, chiral phenanthroline ruthenium complex cation and derivates thereof; and (2) precipitating to separate products produced in the reaction above, and removing the solving agent and the solvent to obtain a pair of enantiomers of the raceme polyhedral cage compound. The resolving method of the raceme polyhedral cage compound has the advantages that the operation method is simple, the resolving effect is good, and the efficiency is high.

Owner:XIAMEN UNIV

Resolution method for axis chiral enantiomers of lesinurad

ActiveUS11365180B2Conveniently recovered and reusedReduce separation costsOrganic active ingredientsSkeletal disorderLesinuradEnantiomer

A resolution method of axial chiral enantiomers of lesinurad (2-(5-bromo-4-(4-cyclopropylnaphthalen-1-yl)-4H-1,2,4-triazol-3-ylthio)acetic acid) adopts inexpensive and readily available quinoline natural products and derivatives thereof, such as quinine, cinchonine, quinidine or cinconidine as resolving agents to react with lesinurad racemate in an organic solvent to form a salt, and the salt is dissociated by acidification so as to obtain optically pure (R)- or (S)-2-(5-bromo-4-(4-cyclopropylnaphthalen-1-yl)-4H-1,2,4-triazol-3-ylthio)acetic acid. The method can give axial chiral enantiomer of lesinurad in R configuration with a chiral purity ee of up to 100% and a total yield of 90% or more. The obtained axial chiral enantiomer of lesinurad in S configuration can reach a chiral purity ee of up to 99.9% and a total yield of 80% or more.

Owner:CHINA RESOURCES SAIKE PHARMA

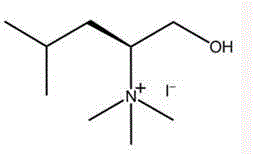

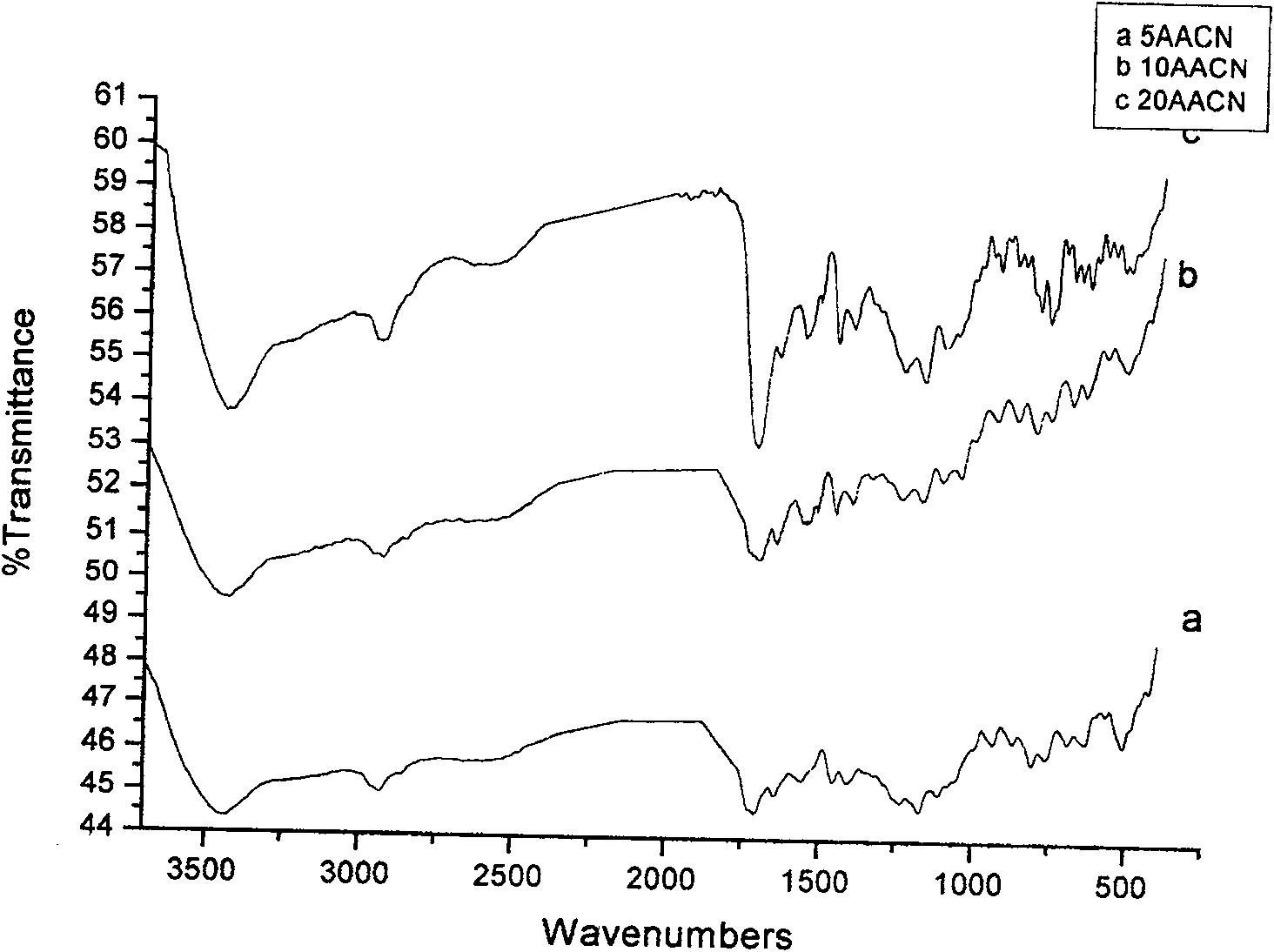

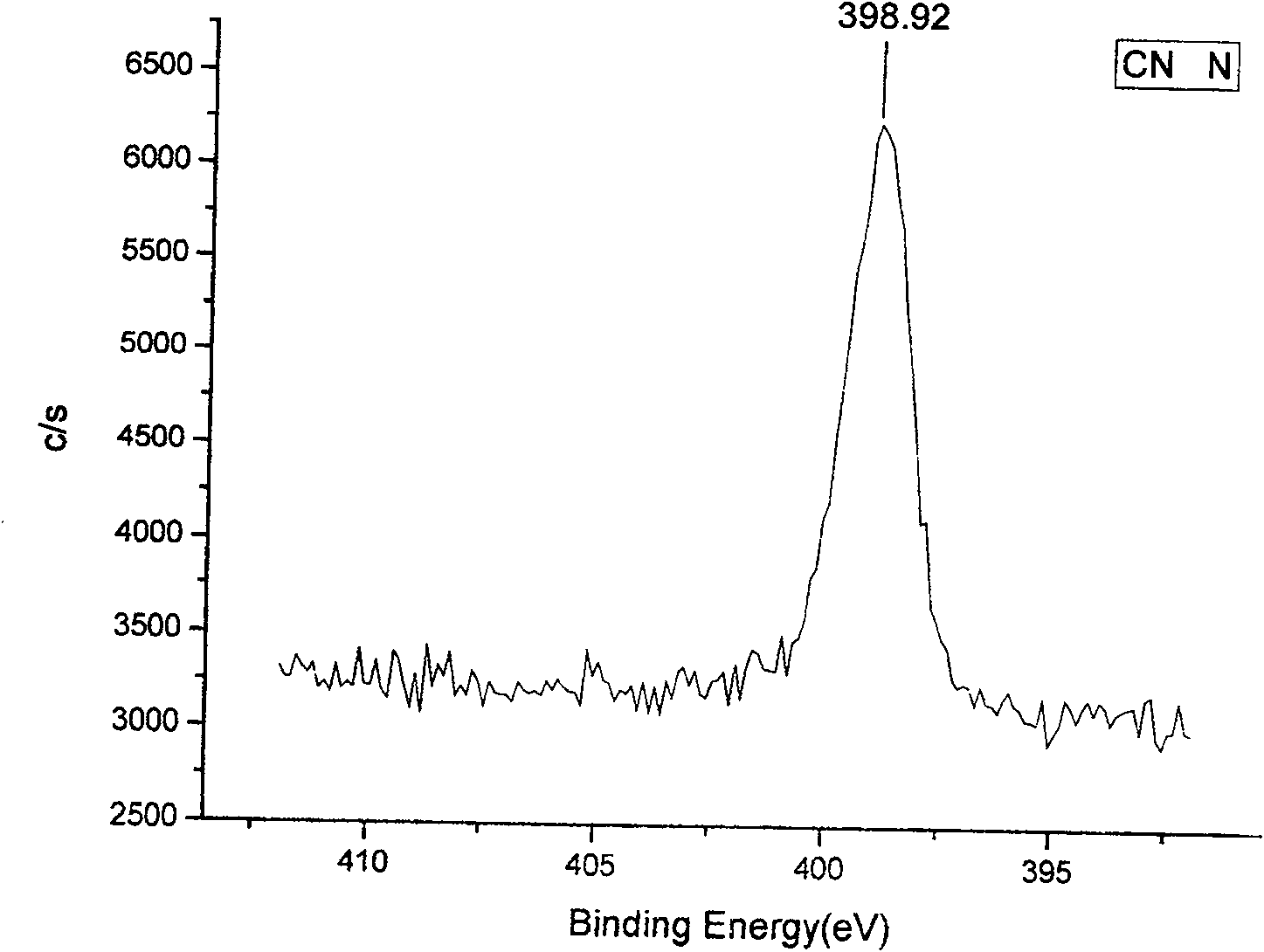

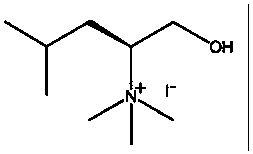

Method for synthesizing polyacrylic acid carrying cinchonine quaternary ammonium salt

The invention relates to a preparation method of polymer-supported cinchonine quaternary ammonium salt. The steps are that: (1) in a reaction kettle, poly acrylic acid is dissolved in deionized water with temperature being controlled between 40 and 55 DEG C to obtain solution A; (2) cinchonine is dissolved in ethanol with 95 percent of concentration to obtain solution B; (3) the solution B is slowly dripped to solution A to obtain solution C after 4-hour reaction; after filtration, the obtained solid is vacuum dried to obtain white massive solid D; (4) the white massive solid D is extracted by using chloroform to obtain the extracted product-poly acrylic acid cinchonine quaternary ammonium salt. The invention has the advantages of simple compounding process flow, shot reaction time, high productivity and low cost, which solves the problems in prior art that product is difficult to be separated from catalyst, the product can not be easily reused and the synthesis cost is too high.

Owner:NORTHWEST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule Synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule](https://images-eureka.patsnap.com/patent_img/26a7905c-7291-44c1-9928-222127a967de/DEST_PATH_IMAGE002.png)

![Synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule Synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule](https://images-eureka.patsnap.com/patent_img/26a7905c-7291-44c1-9928-222127a967de/BDA0002048279860000011.png)

![Synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule Synthesis method of chiral spiro[chroman-4,1'-dihydroindene] molecule](https://images-eureka.patsnap.com/patent_img/26a7905c-7291-44c1-9928-222127a967de/BDA0002048279860000021.png)