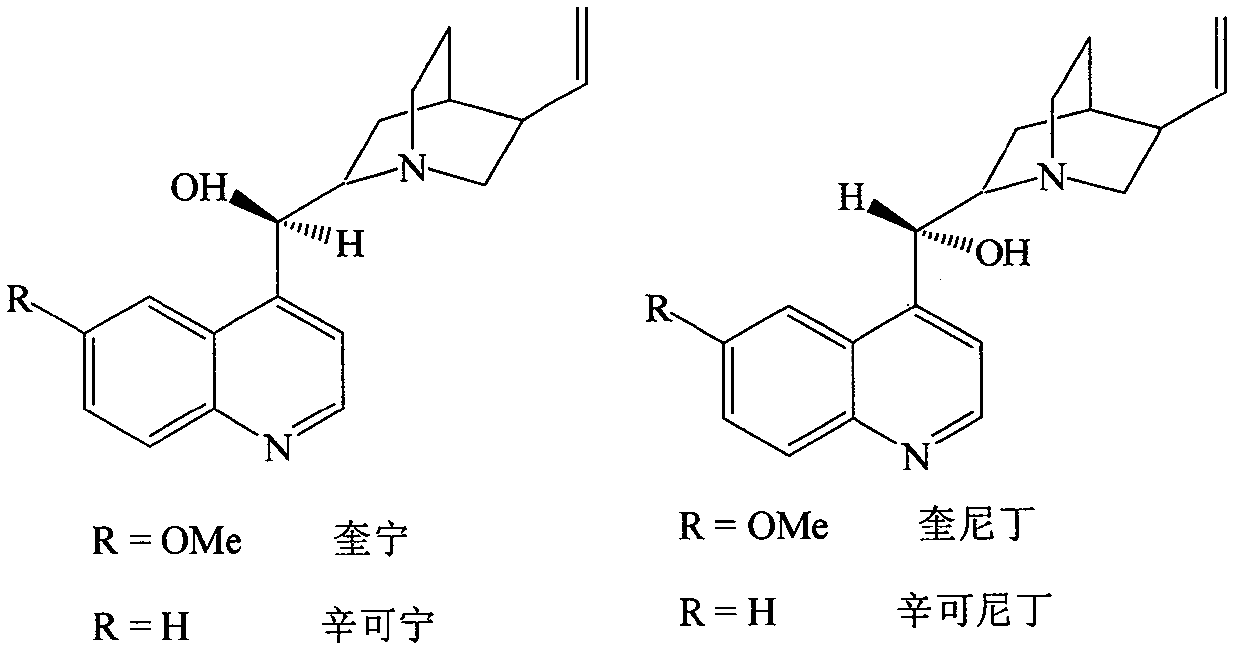

Industrialized production method for efficiently extracting, separating and purifying serial cinchona alkaloid from cinchona bark

A technology of cinchona bark and cinchona, which is applied in the directions of organic chemistry, drug combination, cardiovascular system diseases, etc., can solve the problems of difficult industrialized large-scale production of alkaloids, high energy consumption, and low recovery rate of cinchona alkaloids extraction. , to achieve the effect of good extraction recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

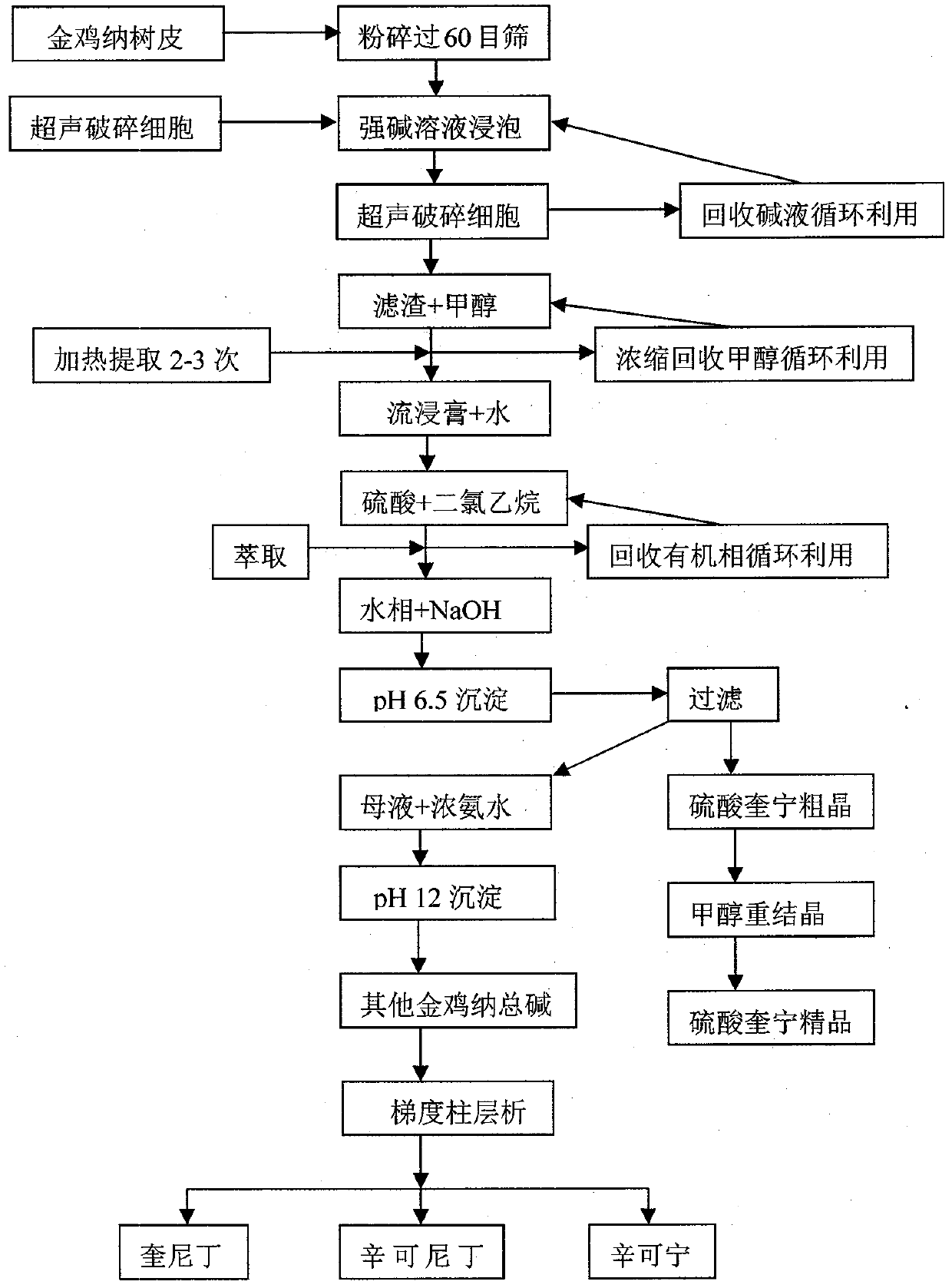

[0021] Embodiment 1 Preparation of quinine alkaloids

[0022] Get the cinchona bark with moisture content less than 3%, pulverize and cross 60 mesh sieves. Weigh 2 kg of cinchona bark powder, soak in 5 L of 5% sodium hydroxide solution, and ultrasonically break the cells for 1 h. Filter and dry to obtain cinchona bark powder, and the lye is recovered and recycled. Put the dried cinchona bark powder into a multi-functional extraction tank, and extract it twice with 16L industrial methanol, each time for 3.5h (the recovery rate of quinine alkaloid extraction detected by HPLC should be greater than 95%, otherwise, extract with 8L methanol 2h), filtered and concentrated to obtain cinchona bark methanol extract fluid extract, methanol recovery and recycling. Disperse the liquid extract above in 2L of water, adjust the pH value to 3.5 with concentrated sulfuric acid, and extract once with 1L of dichloroethane. The organic phase reclaims ethylene dichloride for recycling, the wate...

Embodiment 2

[0023] The preparation of embodiment 2 quinidine, cinchonidine and cinchonine

[0024] Continue to adjust the mother liquor from the previous step to a pH value of 12 with concentrated ammonia water, and continue to precipitate new precipitates from the mother liquor, and filter to obtain 4.6 kg of other total alkaloids. The total alkaloids were column chromatographed and eluted with a gradient of petroleum ether: ethyl acetate = 9:1 to 7:3 to obtain 1.6 kg of quinidine, 1.0 kg of cinchonidine and 1.2 kg of cinchonine respectively as main products. The contents detected by HPLC were all greater than 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com