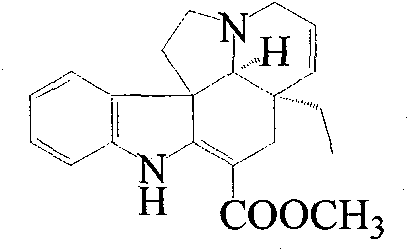

Industrial production process for indole alkaloid tabersonine

A technology of taponin and alkaloids, applied in the industrial production process of indole alkaloids-taponin, can solve the problems of high cost, high energy consumption, large pollution, etc., and achieve the effect of good extraction recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

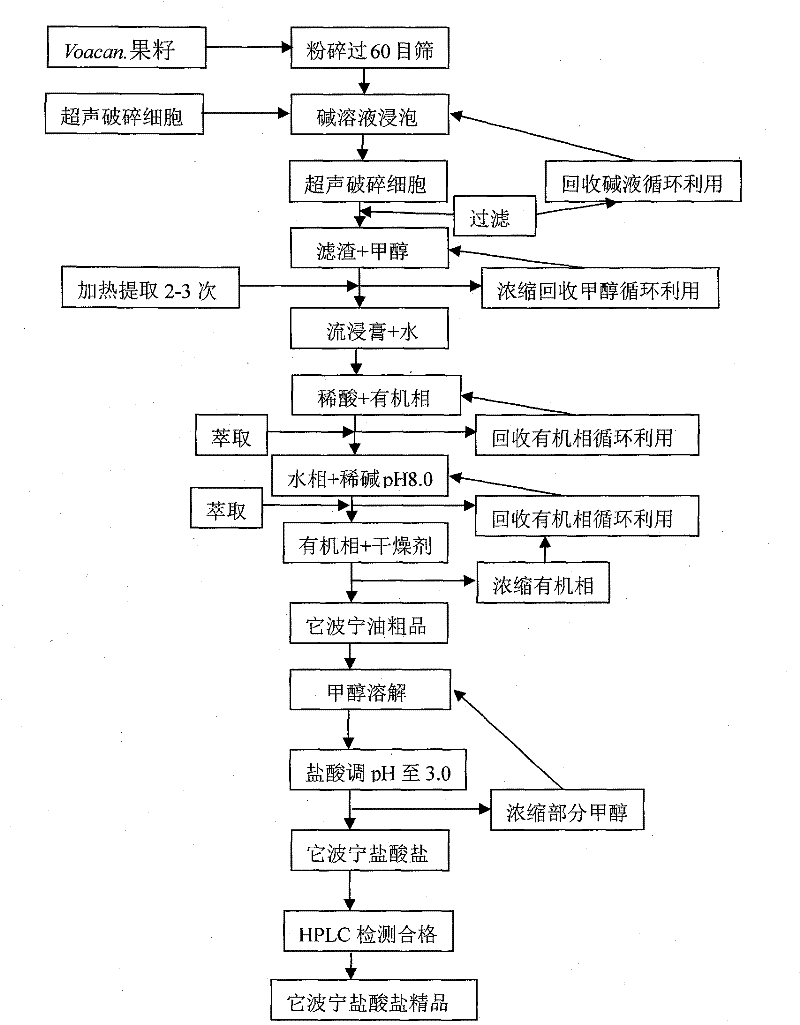

[0024] Embodiment 1 The preparation method 1 of Tabonin alkaloid

[0025] Get Voacanga africana fruit seeds with a moisture content of less than 2%, pulverize and pass through a 60-mesh sieve. Weigh 1 kg of Voacanga africana fruit seed powder, soak in 3 L of sodium hydroxide solution with a pH value of 9, and ultrasonically disrupt cell tissue for 1 h. Filter and dry to obtain Voacanga africana fruit seed powder, and recover and recycle the lye. Put the dried Voacanga africana fruit seed powder in a multi-functional extraction tank, and extract it twice with 6L industrial methanol, each time for 4h (the recovery rate of the bonin alkaloid extraction detected by HPLC should be greater than 98%, otherwise, extract it with 6L methanol 2h, filtered methanol (applicable), filtered and concentrated to obtain Voacanga africana fruit seed methanol extraction fluid extract, methanol recovery and recycling. Disperse the liquid extract above in 3L of water, adjust the pH value to 3.0 w...

Embodiment 2

[0026] Embodiment 2 The preparation method of Tabonin alkaloid 2

[0027] Get Voacanga africana fruit seeds with a moisture content of less than 2%, pulverize and pass through a 60-mesh sieve. Weigh 1 kg of Voacanga africana fruit seed powder, soak in 3 L of ammonia solution with a pH value of 9, and ultrasonically disrupt cell tissue for 1 h. Filter and dry to obtain Voacanga africana fruit seed powder, and recover and recycle the lye. Put the dried Voacanga africana fruit seed powder in a multi-functional extraction tank, and extract it twice with 6L industrial methanol, each time for 4h (the recovery rate of the bonin alkaloid extraction detected by HPLC should be greater than 98%, otherwise, extract it with 6L methanol 2h, filtered methanol (applicable), filtered and concentrated to obtain Voacanga africana fruit seed methanol extraction fluid extract, methanol recovery and recycling. Disperse the above liquid extract in 3L of water, adjust the pH value to 3.0 with dilut...

Embodiment 3

[0028] Embodiment 3 Itbonin hydrochloride preparation method 1

[0029] Heat and dissolve 24.0 g of oily Tabonin alkaloid in 500 mL of anhydrous methanol, then adjust the pH value to 3.0 with concentrated hydrochloric acid, then pump out about 200 mL of methanol under reduced pressure, and cool to precipitate Tabonin coarse crystals. Then recrystallized from methanol to obtain 23.0 g of refined Tabonin hydrochloride. HPLC detection content is greater than 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com