Method for determining tungsten content in tungsten-containing polyethylene composite shielding material

A technology of composite shielding and determination method, applied in the direction of removing a certain component and weighing, etc., can solve the problems of harsh detection conditions, many interference factors, difficult sample digestion, etc., to achieve high repeatability, high detection accuracy, The effect of convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

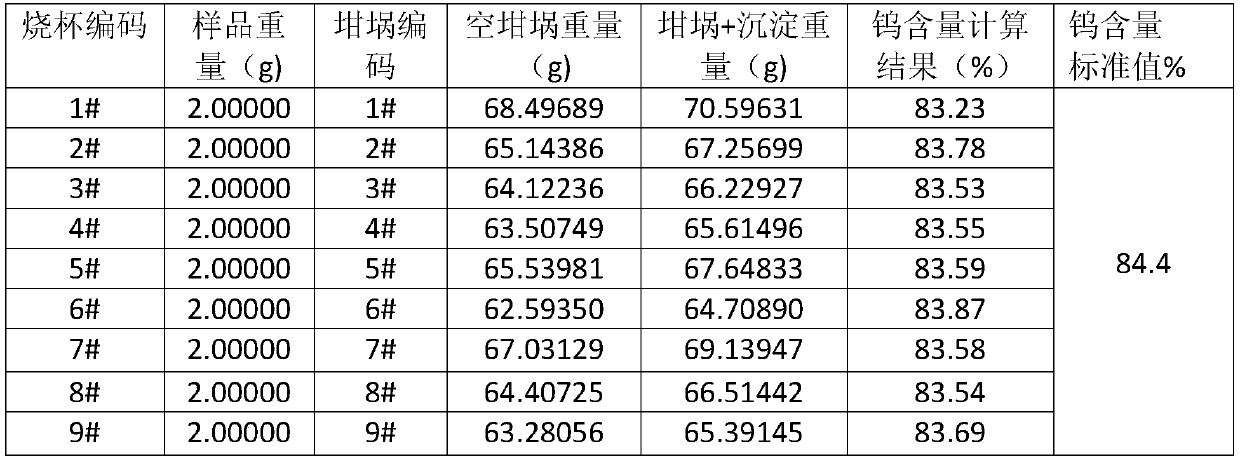

Examples

Embodiment Construction

[0038] The invention provided by the present invention is described below in conjunction with the examples.

[0039] Embodiments of the present invention provide a method for measuring tungsten content in a tungsten-containing polyethylene composite shielding material, which includes the following steps:

[0040] Step 1: Weigh a certain amount of sample of tungsten-containing polyethylene composite shielding material and place it in a quartz crucible, slowly heat up and burn in a muffle furnace, and take it out after cooling. Specifically, in one example, a sample of 1g-2g (denoted as m) tungsten-containing polyethylene composite shielding material is weighed and placed in a 200ml quartz crucible, and the temperature is slowly raised to 500-800°C in a muffle furnace for 3 ~5h, take it out after cooling; in a specific example, the sample of the tungsten-containing polyethylene composite shielding material weighed is accurate to 0.0001g;

[0041] Step 2, transfer the sample to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com