A method for resolution of racemic polyhedral cage compound

A compound and polyhedron technology, applied in the field of chemistry, can solve the problems of time-consuming disassembly process and complexity, and achieve the effect of good disassembly effect, simple operation method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

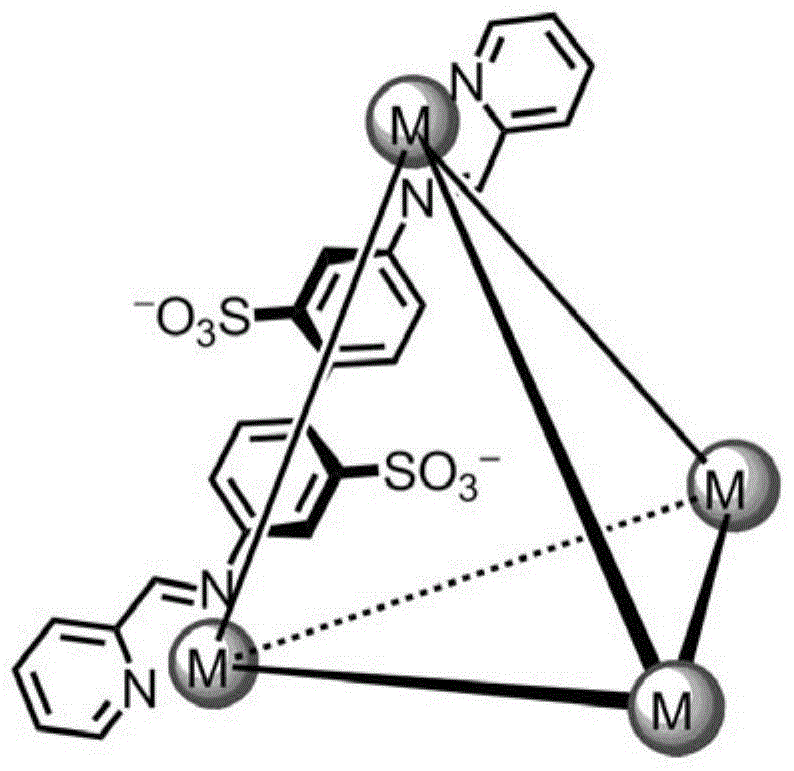

Image

Examples

Embodiment 1

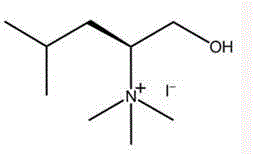

[0019] The resolving agent of the present embodiment adopts the chiral quaternary ammonium salt derived from leucinol, and its structural formula is:

[0020]

[0021] (1) 35 mg of resolving agent and 108 mg of racemic polyhedral cage compound are put into a 25 mL flask and mixed, and 50 mL of methanol is added as a solvent, and reacted at 20 to 50° C. for 1 to 24 hours (preferably, the reaction temperature is 50° C., The reaction time is 1 hour).

[0022] (2) Separating the product obtained after the above reaction is completed, the separation method is mainly to use centrifugation (rotating speed: 3500r / min) to separate the precipitation part and the solution part, and the solution part is decompressed (equipped with a water pump) rotary evaporator) to remove the solvent to obtain the insoluble salt and the easily soluble salt respectively, the resulting insoluble salt and the easily soluble salt are vacuum-dried and the resolving agent is removed by a cation exchange res...

Embodiment 2

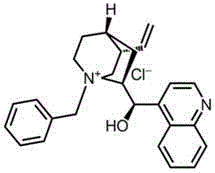

[0024] The resolving agent of the present embodiment adopts cinchonine chloride, and its structural formula is:

[0025]

[0026] (1) Put 17mg resolving agent and 36mg racemic polyhedron cage compound into 25mL flask and mix, add 50mL methanol as solvent, react at 20~50°C for 1~24 hours (preferably, the reaction temperature is 50°C, The reaction time is 1 hour).

[0027] (2) Separating the product obtained after the above reaction is completed, the separation method is mainly to use centrifugation (rotating speed: 3500r / min) to separate the precipitation part and the solution part, and the solution part is decompressed (equipped with a water pump) rotary evaporator) to remove the solvent to obtain the insoluble salt and the easily soluble salt respectively, the resulting insoluble salt and the easily soluble salt are vacuum-dried and the resolving agent is removed by a cation exchange resin to obtain the racemic polyhedral cage compound A pair of enantiomers.

Embodiment 3

[0029] The resolving agent of the present embodiment adopts chiral three (o-phenanthroline) ruthenium complex cations, and its structural formula is:

[0030]

[0031] (1) Put 9 mg of resolving agent and 36 mg of racemic polyhedral cage compound into a 25 mL flask and mix, add 15 mL of methanol as a solvent, and react at 20 to 50° C. for 1 to 24 hours (preferably, the reaction temperature is 50° C., The reaction time is 1 hour).

[0032] (2) Separating the product obtained after the above reaction is completed, the separation method is mainly to use centrifugation (rotating speed: 3500r / min) to separate the precipitation part and the solution part, and the solution part is decompressed (equipped with a water pump) rotary evaporator) to remove the solvent to obtain the insoluble salt and the easily soluble salt respectively, the resulting insoluble salt and the easily soluble salt are vacuum-dried and the resolving agent is removed by a cation exchange resin to obtain the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com