Combined determination method for contents of tungsten and silicon in ferrotungsten

A determination method and technology for silicon content, applied in the field of determination, can solve the problems of difficult control of the operation process, cumbersome inspection process, failure of inspection, etc., and achieve the effects of high precision and accuracy of the method, high detection accuracy, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

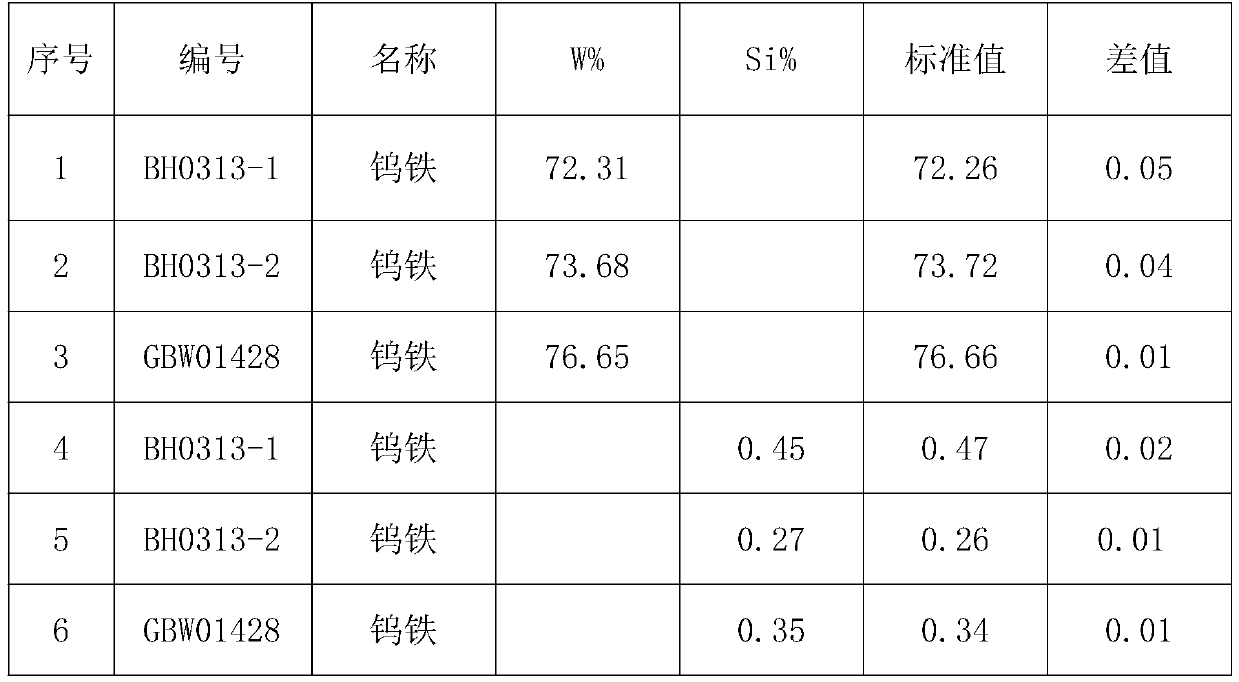

Examples

Embodiment 1

[0042] The principle of this embodiment: put the precipitate together with the filter paper in a platinum crucible, burn it at a high temperature of 750°C for 30 minutes in a muffle furnace, take it out, cool slightly, weigh (w1), add 5ml of hydrofluoric acid, add sulfuric acid (1 +1) 2-3 drops, heated on an electric stove, evaporated to the exhaustion of sulfuric acid white smoke, burned in a muffle furnace at 800°C for 20 minutes, took it out, cooled it, and weighed it (w2).

[0043] This embodiment relates to a method for joint determination of tungsten and silicon content in iron tungsten, said method comprising the following steps

[0044] Step 1, preparation of reagents;

[0045] Step 2, the preparation of cinchonine solution;

[0046] Step three, measure;

[0047] Step four, analysis.

[0048] Preferably, in step 1, the reagents include: sodium peroxide, anhydrous sodium carbonate, hydrochloric acid, nitric acid, hydrofluoric acid, sulfuric acid.

[0049] Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com