Tungsten-contained material treating method

A material and raw material technology, applied in the field of processing tungsten-containing materials, can solve the problems of corrosion of iron equipment, high decomposer price, general operating environment, etc., to achieve good recovery rate, good operating environment, and improve the effect of decomposition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

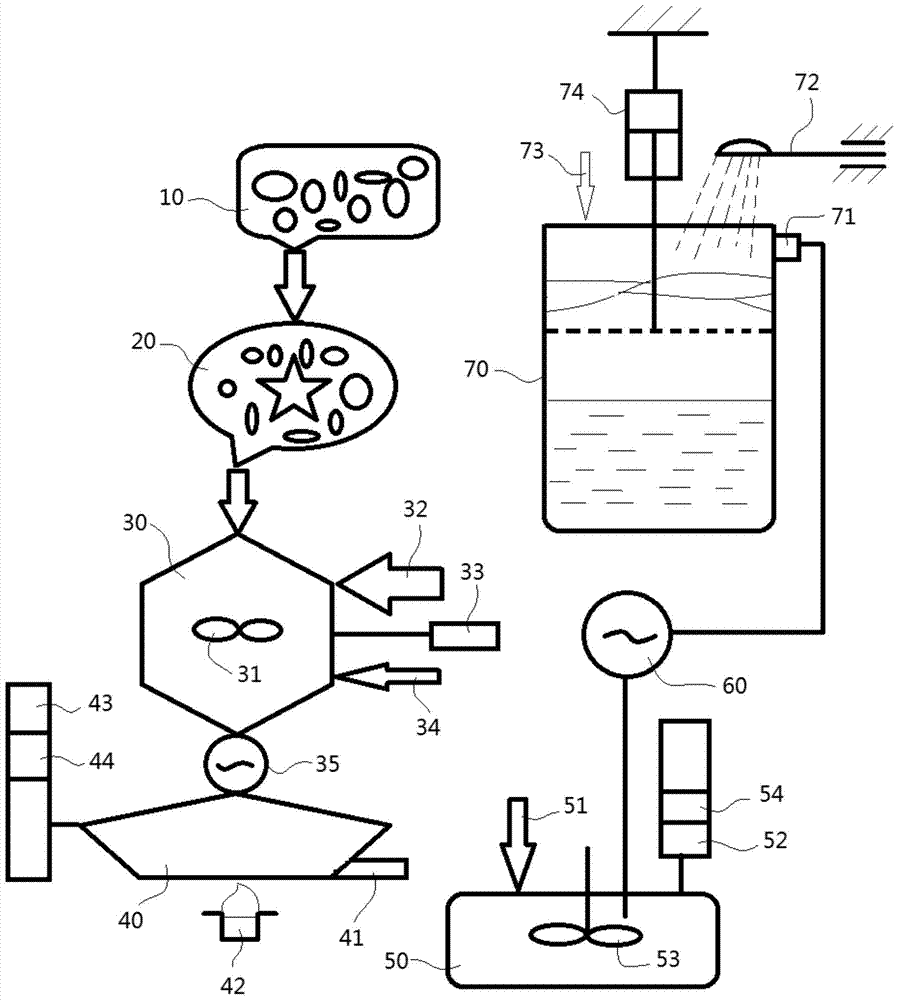

Image

Examples

Embodiment 1

[0042] 1. The process of crushing solid tungsten-containing materials

[0043] (1) Strict ore blending system: m (SiO2) =0.5×m (WO3) ^0.5, where m (SiO2) After the ore blending is completed, the mass fraction of silicon dioxide in the material (%); m (WO3) After the ore blending is completed, the material contains tungsten trioxide mass fraction (%).

[0044] (2) Place the tungsten-containing material in a pulverizing device (preferably a ball mill), and grind until the particle size is less than 75 microns and greater than 95%.

[0045] 2. Slurry mixing process

[0046] Add decomposition agent sodium hydroxide or sodium hydroxide solution (preferably sodium hydroxide) to the mixing tank, and its addition amount is 2.5 times of the theoretical value. Turn on the stirring, and add a small amount of water while adding the decomposing agent, so as to prevent the stirring from being invalid due to excessive viscosity, 1m 3 The final mixing volume of crushed tungsten-containi...

Embodiment 2

[0053] 1. The process of crushing solid tungsten-containing materials

[0054] (1) Strict ore blending system: m (SiO2) ≥0.6×m (WO3) ^0.5, where m (SiO2) After the ore blending is completed, the mass fraction of silicon dioxide in the material (%); m (WO3) After the ore blending is completed, the material contains tungsten trioxide mass fraction (%).

[0055] (2) Place the tungsten-containing material in a pulverizing device (preferably a ball mill), and grind until the particle size is less than 50 microns and greater than 95%.

[0056] 2. Slurry mixing process

[0057] Add decomposition agent sodium hydroxide or sodium hydroxide solution (preferably sodium hydroxide) to the mixing tank, and its addition is 2.1 times of the theoretical value. Turn on the stirring, and add a small amount of water while adding the decomposing agent, so as to prevent the stirring from being invalid due to excessive viscosity, 1m 3 The final mixing volume of crushed tungsten-containing mate...

Embodiment 3

[0064] 1. The process of crushing solid tungsten-containing materials

[0065] (1) Strict ore blending system: m (SiO2) ≥0.65×m (WO3) ^0.5, where m (SiO2) After the ore blending is completed, the mass fraction of silicon dioxide in the material (%); m (WO3) After the ore blending is completed, the material contains tungsten trioxide mass fraction (%).

[0066] (2) Place the tungsten-containing material in a crushing device (preferably: a ball mill), and grind it until the particle size is less than 45 microns and greater than 97%.

[0067] 2. Slurry mixing process

[0068] Add decomposition agent sodium hydroxide or sodium hydroxide solution (preferably sodium hydroxide) to the mixing tank, and its addition is 2.3 times of the theoretical value. Turn on the stirring, and add a small amount of water while adding the decomposing agent, so as to prevent the stirring from being invalid due to excessive viscosity, 1m 3 The final mixing volume of crushed tungsten-containing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com