Degradable copolyester based on triethylene glycol, preparation and application

A technology of triethylene glycol and copolyester, which is applied in the field of polymer synthesis and can solve problems such as city landscape and ecological environment damage, white pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

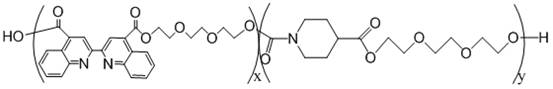

Method used

Image

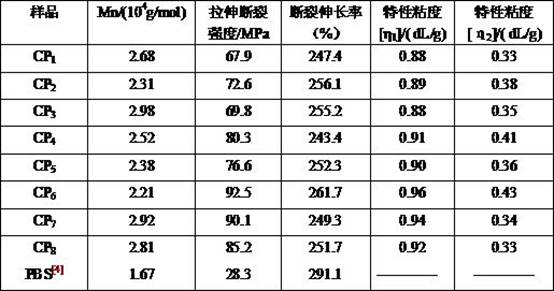

Examples

Embodiment 1

[0035] Add 3.443g (10mmol) of 2,2-bicinchoninic acid, 2.442g (14mmol) of piperidine-1,4 dicarboxylic acid, 4.200g (28mmol) of triethylene glycol and 0.013g ( 0.042mmol) of antimony acetate. Nitrogen protection was introduced, and the reaction was stirred at 180°C for 3 h to obtain an esterified product. Continue to raise the temperature of the esterification product to 240°C, control the absolute pressure in the reaction system at about 80 Pa, and react for 4 hours to obtain the crude product of the polycondensation product. Add 30 mL of chloroform to the crude polyester, soak for 2 hours and then filter; take the clear liquid and add it dropwise to 50 ml of methanol to obtain a cloudy liquid, centrifuge and filter to obtain a solid, wash the obtained solid with ethanol, and filter again The solid was dried at 60°C for 2 h to obtain 8.268 g of copolyester CP 1 , and the yield was 87.38%.

[0036] Collect the copolyester CP of 100g 1 , mixed evenly with 1g chain extender ep...

Embodiment 2

[0040] Add 3.443g (10mmol) of 2,2-biscinchoninic acid, 2.791g (16mmol) of piperidine-1,4 dicarboxylic acid, 4.200g (28mmol) of triethylene glycol and 0.013g ( 0.042mmol) of antimony acetate. Nitrogen protection was introduced, and the reaction was stirred at 180°C for 3 h to obtain an esterified product. Continue to raise the temperature of the esterification product to 240°C, control the absolute pressure in the reaction system at about 80 Pa, and react for 4 hours to obtain the crude product of the polycondensation product. Add 30 mL of chloroform to the crude polyester, soak for 2 hours and then filter; take the clear liquid and add it dropwise to 50 ml of ethanol to obtain a cloudy liquid, centrifuge and filter to obtain a solid, wash the obtained solid with ethanol, and filter again The solid was dried at 60°C for 2 h to obtain 9.105 g of copolyester CP 2 , the yield is 90.05%.

[0041] Collect the copolyester CP of 100g 2 , mix uniformly with 1g chain extender epoxy ...

Embodiment 3

[0045] Add 3.787g (11mmol) of 2,2-bicinchoninic acid, 2.442g (14mmol) of piperidine-1,4 dicarboxylic acid, 4.200g (28mmol) of triethylene glycol and 0.013g ( 0.042mmol) of antimony acetate. Nitrogen protection was introduced, and the reaction was stirred at 180°C for 3 h to obtain an esterified product. Continue to raise the temperature of the esterification product to 240°C, control the absolute pressure in the reaction system at about 80 Pa, and react for 4 hours to obtain the crude product of the polycondensation product. Add 30 mL of chloroform to the crude polyester, soak for 2 hours and then filter; take the clear liquid and add it dropwise to 50 ml of isopropanol to obtain a cloudy liquid, centrifuge, filter to obtain a solid, wash the obtained solid with ethanol, and filter again The final solid was dried at 60°C for 2h to obtain 8.781g of copolyester CP 3 , and the yield was 88.17%.

[0046] Collect the copolyester CP of 100g 3 , mix uniformly with 1g chain extend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com