Continuous aluminium oxide base ceramic fibre preparation method

A technology of ceramic fibers and base ceramics, applied in the direction of inorganic raw materials such as rayon, can solve the problems of affecting the uniformity of fiber microstructure, difficult dispersion of ceramic powder, unfavorable mechanical properties, etc., so as to suppress the tendency of cracking and avoid instability. The effect of strong flexibility and process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

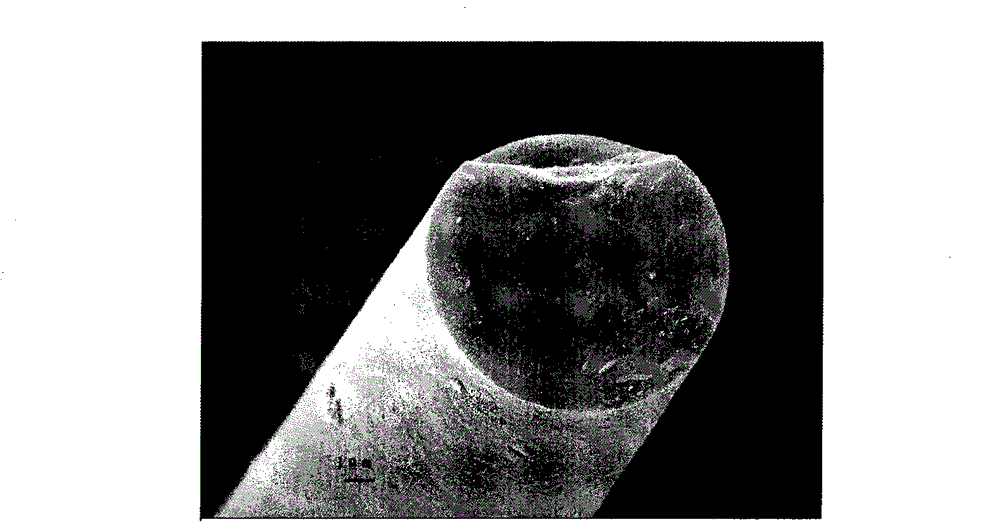

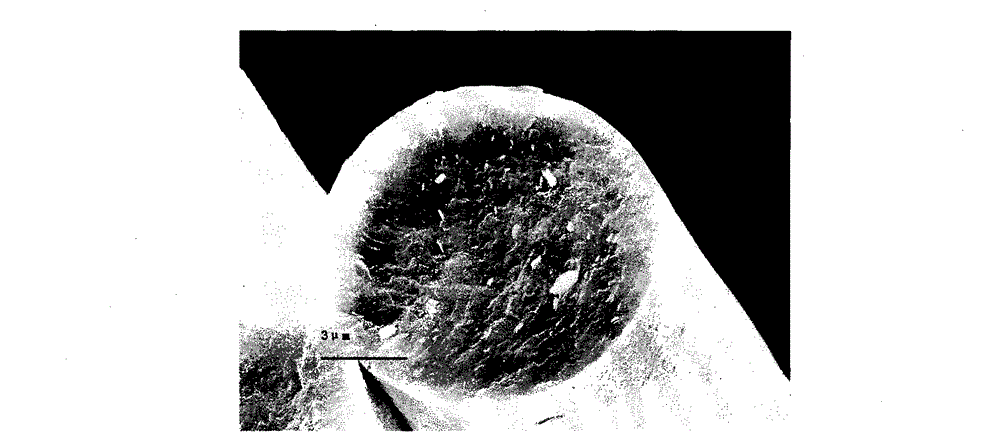

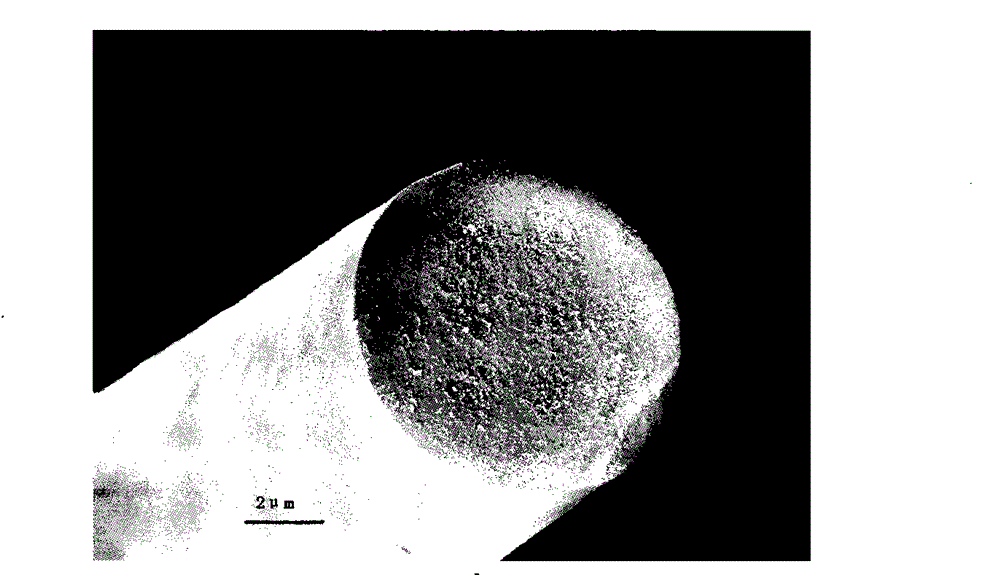

Image

Examples

Embodiment 1

[0030] (1) Add 200ml of aluminum trichloride aqueous solution (1mol / L) and 27g of metal aluminum powder into a 500ml round bottom flask, and heat to reflux for 12h to completely dissolve the aluminum powder. After cooling, filter with filter paper to obtain a clear alumina sol.

[0031] (2) 11.18g ethyl orthosilicate (Si(OC 2 h 5 ) 4 ) was dissolved in 40ml of absolute ethanol, 10ml of ammonia solution (1%) was added, after hydrolysis at 60°C for 24h, dilute hydrochloric acid was added to adjust the pH value to 4, and a silica sol with an average particle diameter of 30nm was obtained.

[0032] (3) 5 g of polyvinyl alcohol with an average degree of polymerization of 1750 and a degree of alcoholysis of 99% is dissolved in 95 g of water to form a 5% solution to obtain a spinning aid.

[0033] (4) After stirring and mixing the alumina sol obtained in step (1) with the silica sol obtained in step (2), then add 50 g of spinning aid obtained in step (3), and after stirring and mi...

Embodiment 2

[0039] (1) Heat 100ml of aluminum trichloride aqueous solution (2mol / L) and 18.2g of metal aluminum foil to reflux for 12h, and the aluminum foil is completely dissolved. After the resulting liquid was cooled, it was filtered with filter paper to obtain a clear alumina sol.

[0040] (2) 18.24g methyl orthosilicate (Si(OCH 3 ) 4 ) was dissolved in 60ml of absolute ethanol, 10ml of ethylenediamine aqueous solution (0.5%) was added, hydrolyzed at 50°C for 12 hours to obtain a silica sol, and dilute hydrochloric acid was added to adjust the pH value to 3.5 to obtain silica with an average particle size of 10nm Sol.

[0041] (3) 20 g of polyvinylpyrrolidone (K90) was dissolved in 80 g of water to form a 20% solution to obtain a spinning aid.

[0042] (4) After stirring and mixing the aluminum sol obtained in step (1) with the silica sol obtained in step (2), then add 40 g of spinning aid obtained in step (3), and stir and mix it at 70 Concentrate under reduced pressure at °C to...

Embodiment 3

[0048] (1) Heat 1000ml aluminum nitrate aqueous solution (0.3mol / L) and 48.6g metal aluminum foil to reflux for 24 hours, and the aluminum foil is completely dissolved. After the resulting liquid was cooled, it was filtered with filter paper to obtain a clear alumina sol.

[0049] (2) 145.8g ethyl orthosilicate (Si(OC 2 h 5 ) 4 ) was dissolved in 500ml of absolute ethanol, 20ml of hexamethylenetetramine aqueous solution (20%) was added, hydrolyzed at 70°C for 18h to obtain a silica sol, and dilute hydrochloric acid was added to adjust the pH value to 3 to obtain a silica sol with an average particle diameter of 100nm. Silica sol.

[0050] (3) 10 g of polyacrylic acid having an average degree of polymerization of 100,000 was dissolved in 90 g of water to form a 10% solution to obtain a spinning aid.

[0051] (4) After stirring and mixing the aluminum sol obtained in step (1) with the silica sol obtained in step (2), then add 100 g of spinning aid obtained in step (3), and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com