Ethylene glycol composition

A technology of ethylene glycol and composition, which is applied in the field of ethylene glycol composition obtained by hydrogenation of oxalate, which can solve the problems of high production cost and single source of raw materials for the production of ethylene glycol composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

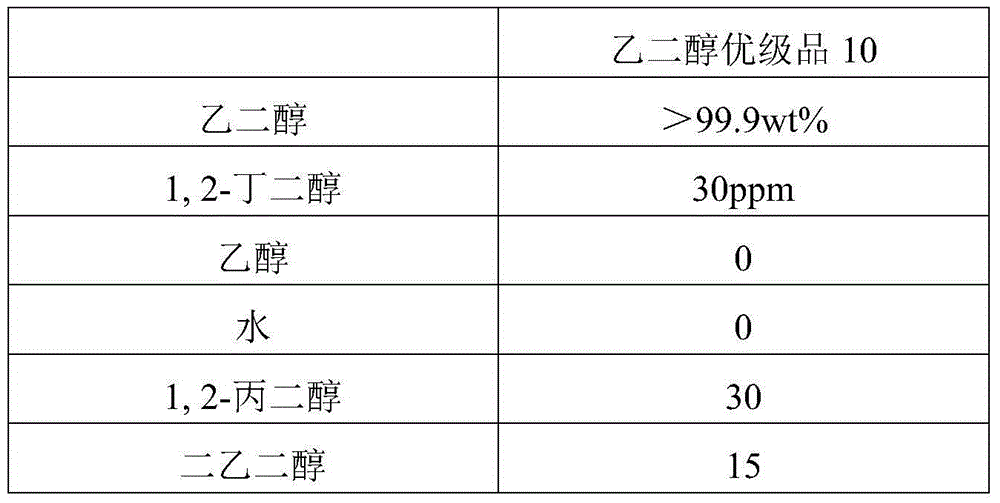

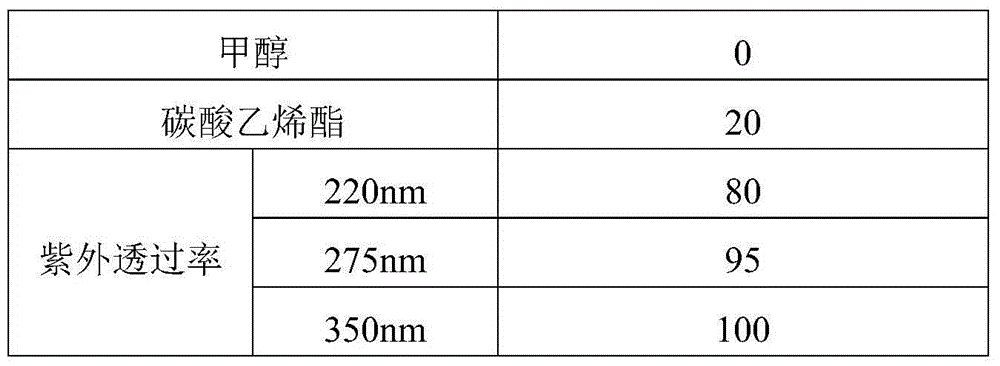

Embodiment 1

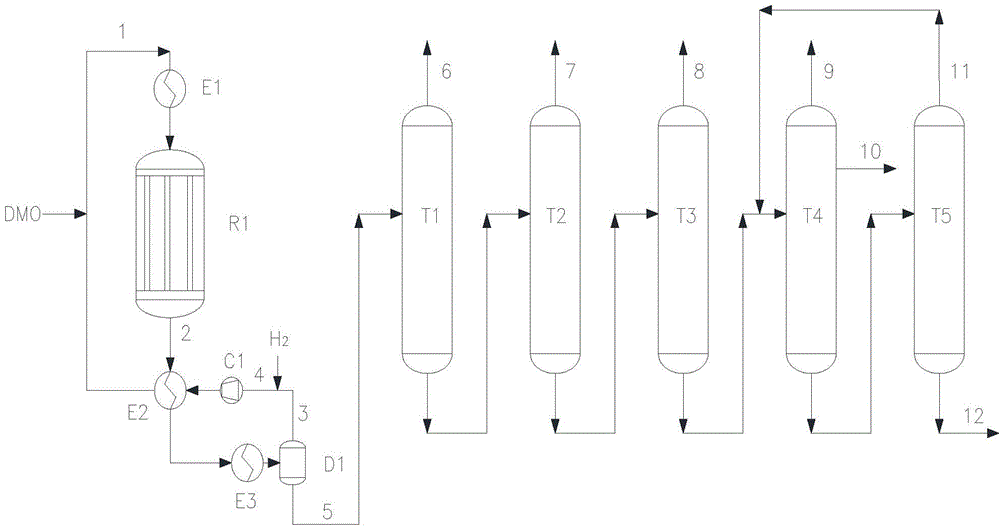

[0069] Combine below figure 1 Schematic of the reaction-separation system shown. At a reaction temperature of 150-300°C and a reaction pressure of 2.0-4.5 MPa, the mixed raw material of dimethyl oxalate and hydrogen passes through a fixed bed filled with catalyst, and the reaction produces methanol, ethanol, water, dimethyl ether, carbonic acid Vinyl ester, methyl glycolate, 1,2-propanediol, 1,2-butanediol, ethylene glycol monomethyl ether, diethylene glycol and their mixtures of crude ethylene glycol products, the catalyst contains Cu-based catalysts on silica. The unreacted hydrogen is recovered by gas-liquid separation and recycled to the reaction system, and the liquid phase product obtained by gas-liquid separation enters the product separation and refining system.

[0070] The specific implementation is as follows:

[0071]The feed 1 of hydrogen and dimethyl oxalate passes through the raw material gasifier E1 and enters the hydrogenation reactor R1 after being vaporiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com