Method for synthesizing cinchona alkaloids microwave radiation non-solvent

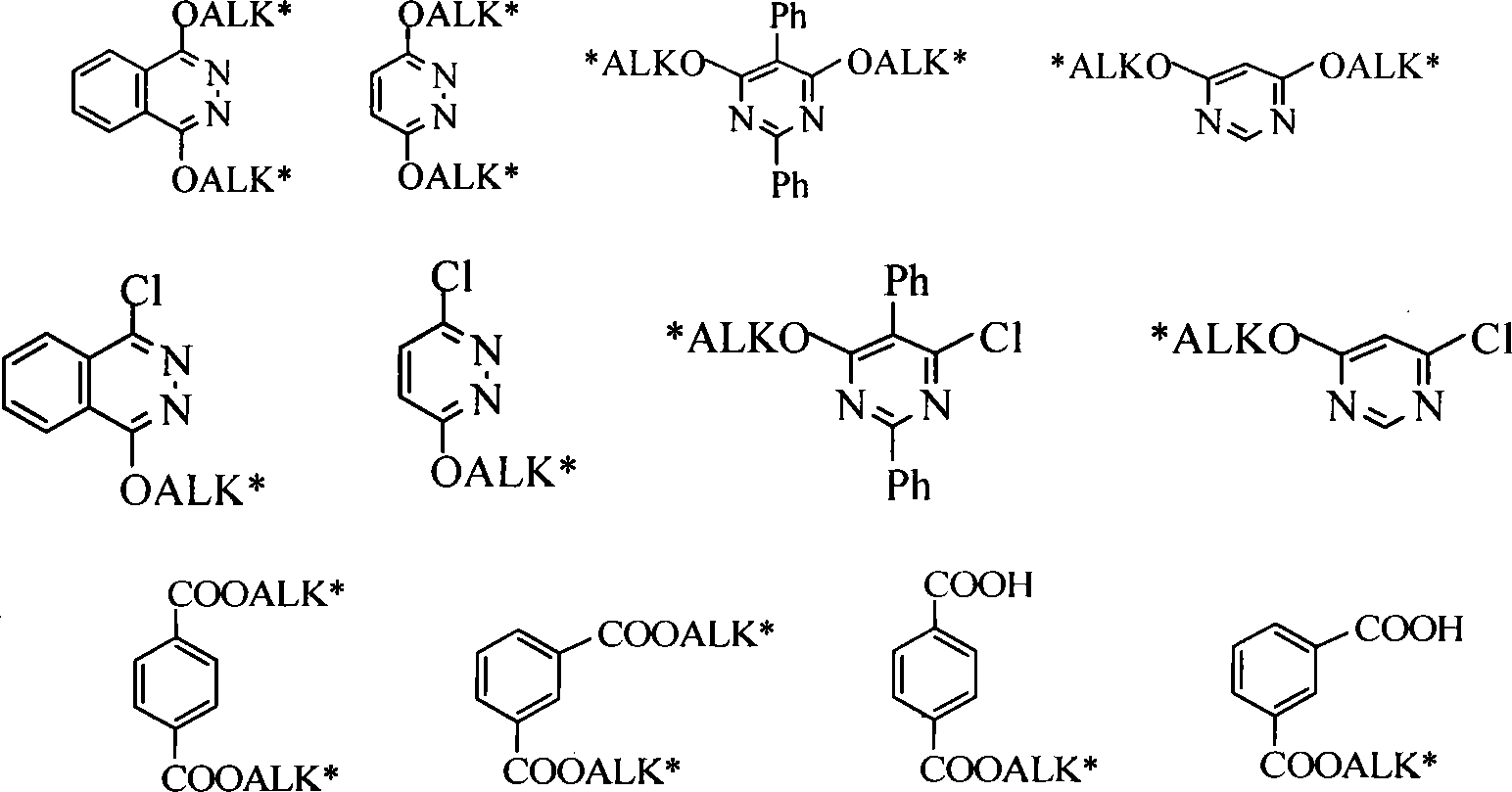

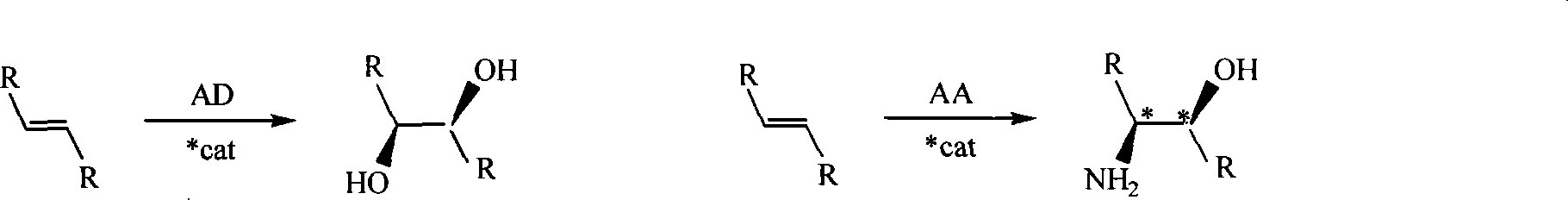

A technology of cinchona alkaloids and a synthesis method is applied in the field of solvent-free synthesis of cinchona alkaloid derivatives by microwave irradiation, and the effects of increasing power, mild reaction conditions and prolonging reaction time are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

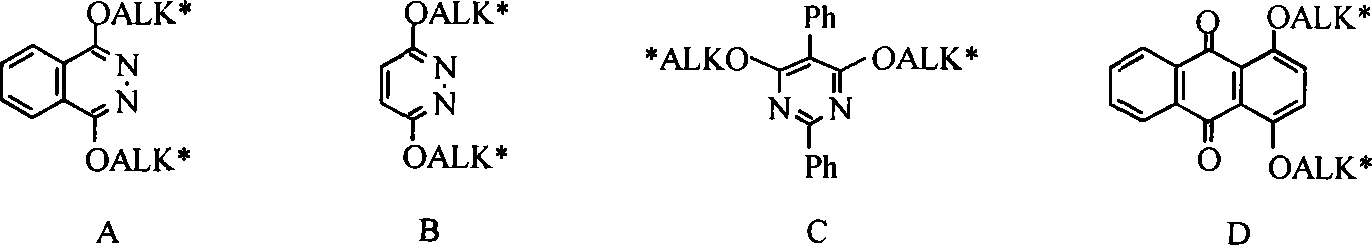

[0026] Embodiment 1: the synthesis of derivative 1:

[0027] In the 50mL round bottom flask, add 0.295g (0.0015mol) 1,4-dichloro-2,3 naphthyridine, 0.487g (0.0015mol) quinine, 0.84g (0.006mol) K 2 CO 3 , a catalytic amount of tetrabutylammonium bromide (TBAB), magnetically stirred and mixed evenly, placed in a microwave reactor, adjusted power 850W, temperature 125°C, reacted for 10min, monitored by TLC, added CH 2 Cl 2 After extraction (25 mL×3), the organic layers were combined, concentrated under reduced pressure, and separated by column chromatography to obtain 0.58 g of a light yellow solid with a yield of 68.7%.

Embodiment 2

[0028] Embodiment 2: the synthesis of derivative 2:

[0029] In the 50mL round bottom flask, add 0.295g (0.0015mol) 1,4-dichloro-2,3 naphthyridine, 0.97g (0.003mol) quinine, 1.7g (0.012mol) K 2 CO 3 , a catalytic amount of tetrabutylammonium chloride, magnetically stirred and mixed evenly, placed in a microwave reactor, adjusted power 850W, temperature 135°C, reacted for 5min, monitored by TLC, added CH after the reaction was completed 2 Cl 2 Extract (25mL×3), combine the organic layers, concentrate under reduced pressure, and separate by flash column chromatography, the yield is 73.8%.

Embodiment 3

[0030] Embodiment 3: the synthesis of derivative 3:

[0031] In the 50mL round bottom flask, add 1.77g (0.006mol) cinchonine, 1.19g (0.006mol) 1,4-dichloro-2,3 naphthyridine, 3.38g (0.024mol) K 2 CO 3 , a catalytic amount of tetrabutylammonium bromide (TBAB), magnetically stirred and mixed evenly, placed in a microwave reactor, adjusted power 800W, temperature 120°C, reacted for 10min, monitored by TLC, added CH 2 Cl 2 After extraction (75mL×3), the combined organic layers were concentrated under reduced pressure and separated by flash column chromatography with a yield of 75.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com