Method for synthesizing polyacrylic acid carrying cinchonine quaternary ammonium salt

A technology of polyacrylic acid and synthesis method, which is applied in the field of synthesizing polymer-loaded cinchonine quaternary ammonium salt, which can solve the problems of difficult separation of product and catalyst, difficult re-use, high synthesis cost, etc., and achieves low cost, short reaction time and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

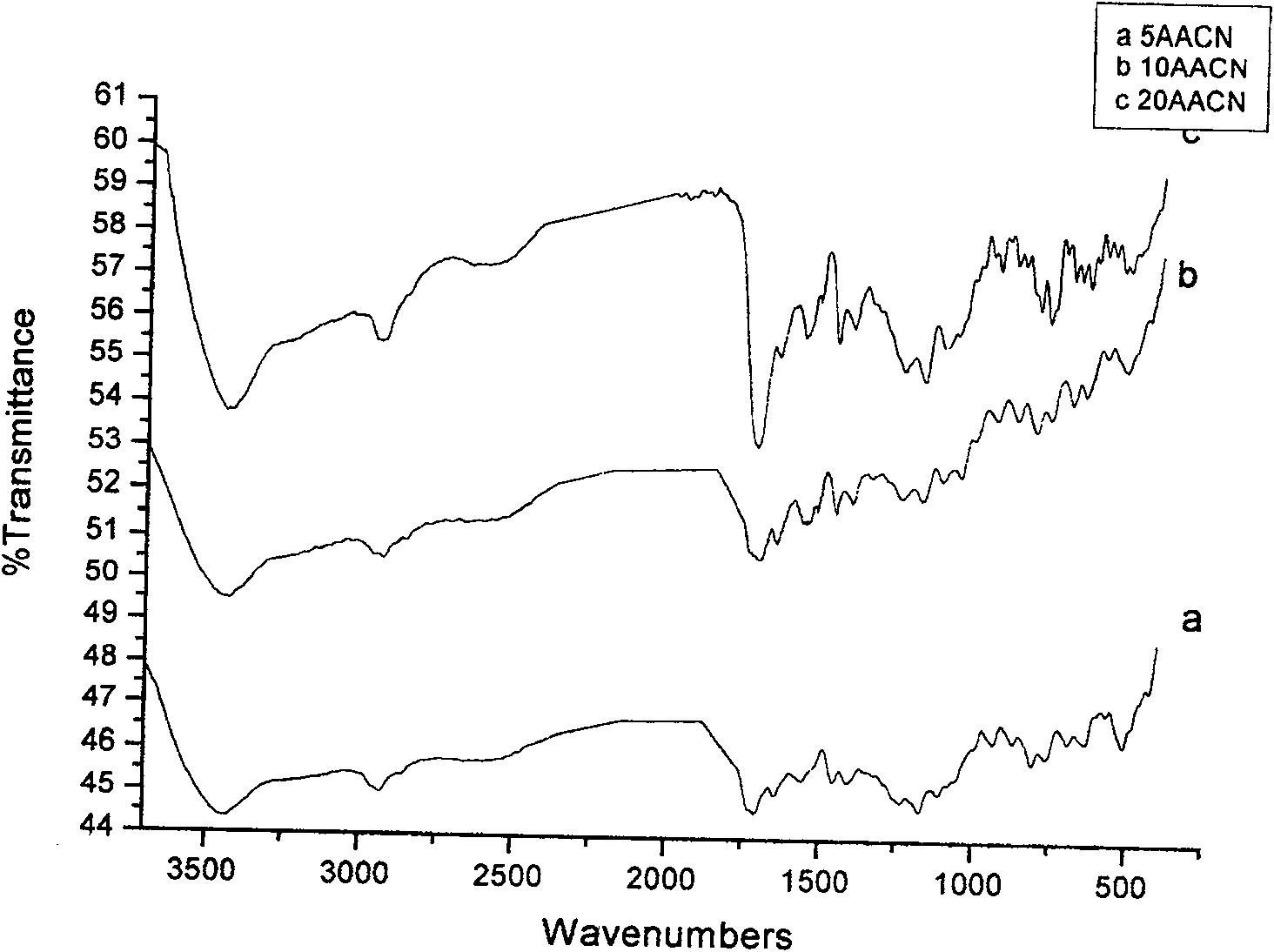

Embodiment 1

[0034] The cinchonine used in the present invention is analytically pure and imported from Shanghai Xingzhi Chemical Factory.

[0035] The synthesis steps of polymer-loaded cinchonine quaternary ammonium salt are: in a reactor, 0.72g polyacrylic acid is dissolved in deionized water, and the temperature is controlled at 40°C to obtain solution A; 0.588g cinchonine is dissolved in 95% ethanol, Obtain solution B; Then solution B is slowly added dropwise to solution A, and reacts for 4 hours to obtain reaction solution C; Then, the solid obtained by filtering reaction solution C is vacuum-dried to obtain off-white blocky solid D, which is treated with chloroform The solid D is extracted to obtain the product—polyacrylic acid cinchonine quaternary ammonium salt.

Embodiment 2

[0037] In the reaction kettle, dissolve 0.72g of polyacrylic acid in deionized water, and control the temperature at 50°C to obtain solution A; dissolve 1.44g of cinchonine in 95% ethanol to obtain solution B; then slowly add solution B to React in solution A for 4 hours to obtain reaction solution C; then, filter reaction solution C to obtain solid and dry it in a vacuum to obtain off-white blocky solid D, and extract solid D with chloroform to obtain the product—polyacrylic acid cinchonine quaternary ammonium salt.

Embodiment 3

[0039] In the reaction kettle, dissolve 0.72g of polyacrylic acid in deionized water, and control the temperature at 55°C to obtain solution A; dissolve 2.88g of cinchonine in 95% ethanol to obtain solution B; slowly add solution B to React in solution A for 4 hours to obtain reaction solution C; then, filter reaction solution C to obtain solid and vacuum dry to obtain off-white blocky solid D, and extract solid D with chloroform to obtain the product—polyacrylic acid cinchonine quarter ammonium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com