Disposable thermal telescopic switch material and method for preparing same

A switch material and thermal expansion technology, applied in the direction of thermal switch components, etc., can solve the problems of low temperature, unsatisfactory switching equipment, narrow temperature control range, etc., and achieve the effect of simple preparation method, cheap raw materials, and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

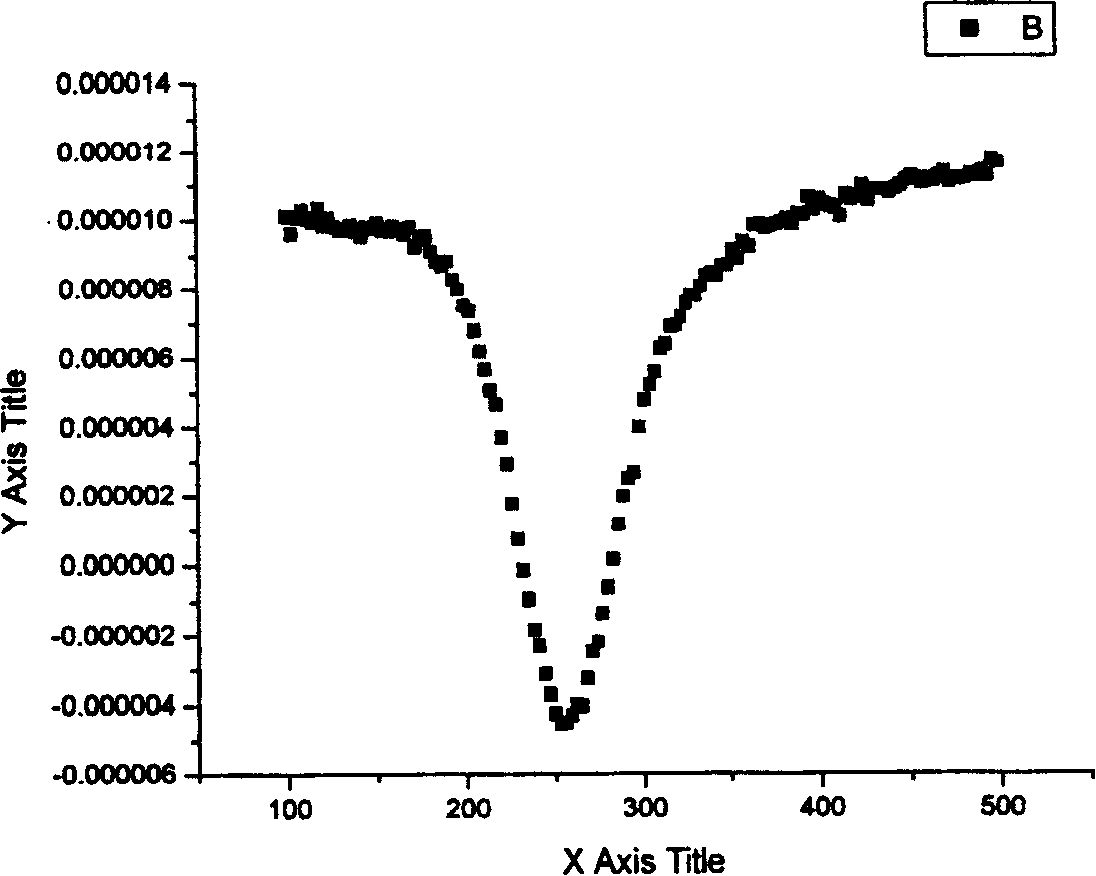

[0008] Embodiment 1: La is taken as 1: 2 by molar ratio 2 o 3 (lanthanum oxide) and CeO 2 (Cerium oxide) powders were mixed and ground for 20 minutes, then the sample was heated to 1400°C for 24 hours at a constant temperature, then slowly cooled to room temperature, and the operation was repeated twice, and the synthesized powder sample was pressed into a steel mold at 90 MPa. Strip, sintered at 1450°C. The heat shrinkage curve of this ceramic material is as follows Figure 1 . attached Figure 1 It is the thermal shrinkage curve in the temperature range of Example 1 of the present invention; wherein the abscissa is temperature, and the ordinate is physical expansion coefficient. From embodiment 1 and accompanying drawing, we can find out, the material that this method obtains can make such a kind of switch material: when lower than 204 ℃ the low temperature area needs switch connection, when the temperature is higher than 204 ℃ and lower than 256 A switch material that a...

Embodiment 2

[0009] Embodiment 2: La is taken as 1: 1 by molar ratio 2 o 3 (lanthanum oxide) and CeO 2 (Cerium oxide) powders were mixed and ground for 25 minutes, then the sample was heated to 1200°C for 18 hours at a constant temperature, then slowly cooled to room temperature, and the operation was repeated twice, and the synthesized powder sample was pressed into a steel mold at 120MPa. Strip, sintered at 1550°C.

Embodiment 3

[0010] Embodiment 3: Take La as 1:4 in molar ratio 2 o 3 (lanthanum oxide) and CeO 2 (Cerium oxide) powders were mixed and ground for 30 minutes, then the sample was heated to 1500°C for 12 hours at a constant temperature, then slowly cooled to room temperature, and the operation was repeated twice, and the synthesized powder sample was pressed into a steel mold at 150MPa. Strip, sintered at 1650°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com