Novel noise reduction and bacteriostasis method for water cooling tower

A cooling water tower, a new method of technology, applied in separation methods, chemical instruments and methods, water shower coolers, etc., can solve problems such as environmental protection and negative impact on staff, damage to sound insulation walls, and reduced heat exchange efficiency, and reduce water vapor. Evaporative and blow-off losses, no site requirements, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

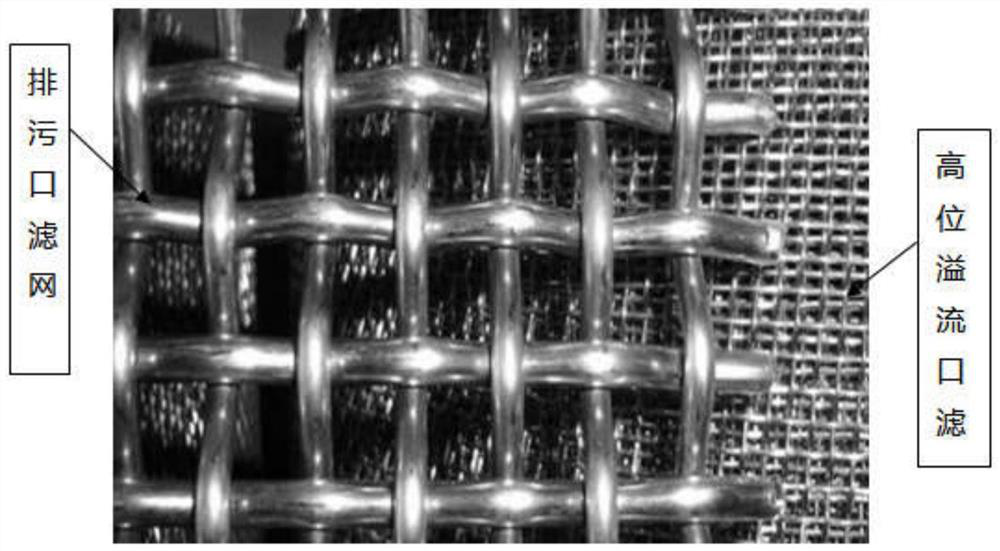

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] Such as figure 1 Shown, a kind of cooling tower noise reduction and bacteriostasis novel method of the present invention, this method is to drop into high-density polyethylene black vacuum plastic ball (as figure 1 ), the number of high-density polyethylene black vacuum plastic balls should be sufficient to cover the surface of the water body in the tower pool, and the rounded curved surface of the spheres can be used to change the impact direction of the water droplets falling from the cooling tower's sprinkler tray, thereby reducing and absorbing the spraying noise of the cooling tower.

[0018] Because the density of high-density polyethylene black vacuum plastic ball is lower than that of water, it can float on the surface of the water body, absorb the heat energy of the sun preferentially, isolate the sunlight from irradia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com