Anti-off-tracking chip mounter capable of replacing suction nozzle

A technology of anti-deviation and placement machine, applied in the direction of electrical components, electrical components, etc., can solve the problems of glue nozzles sticking together, glue viscosity is high, affecting the quality of equipment placement processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

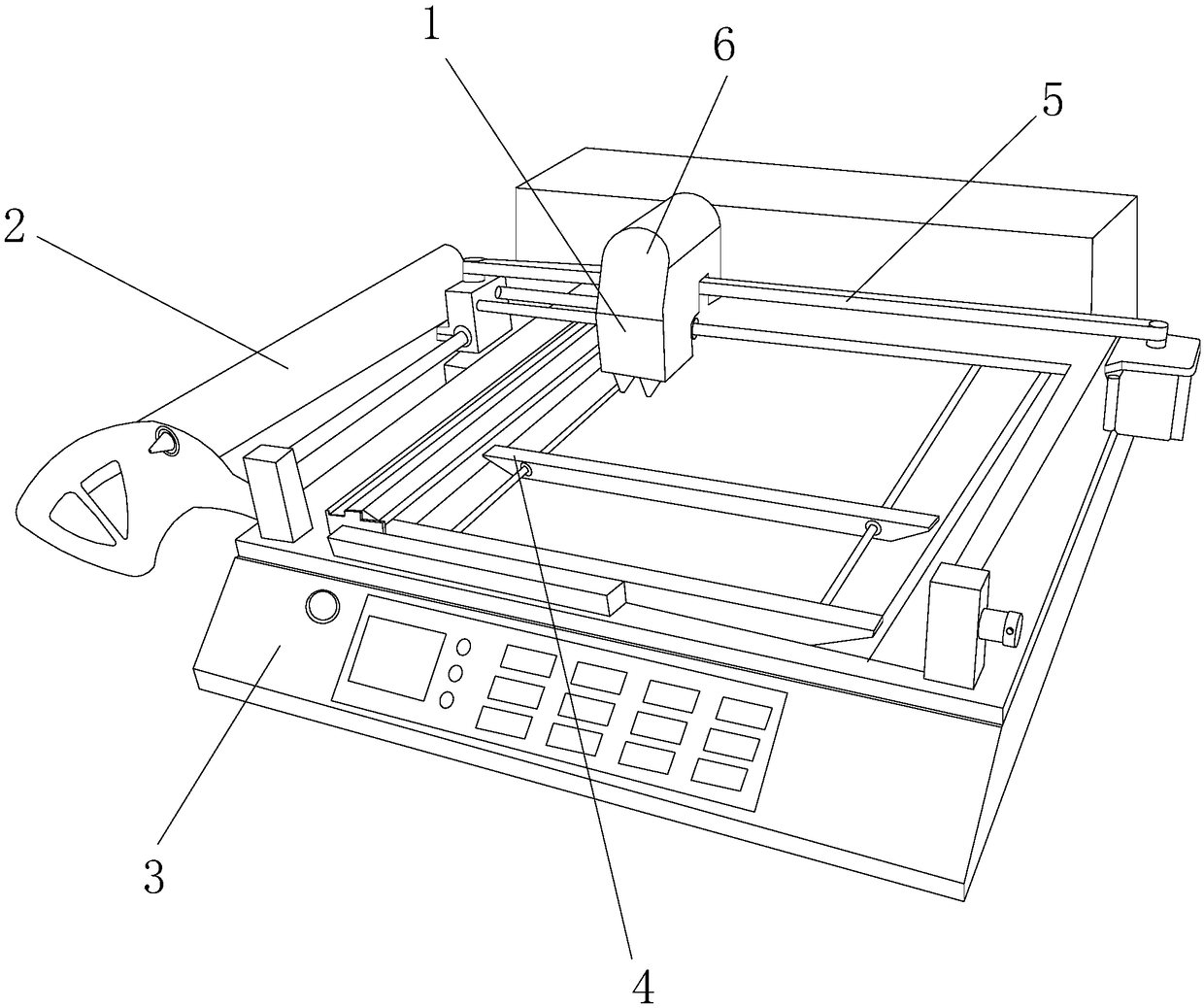

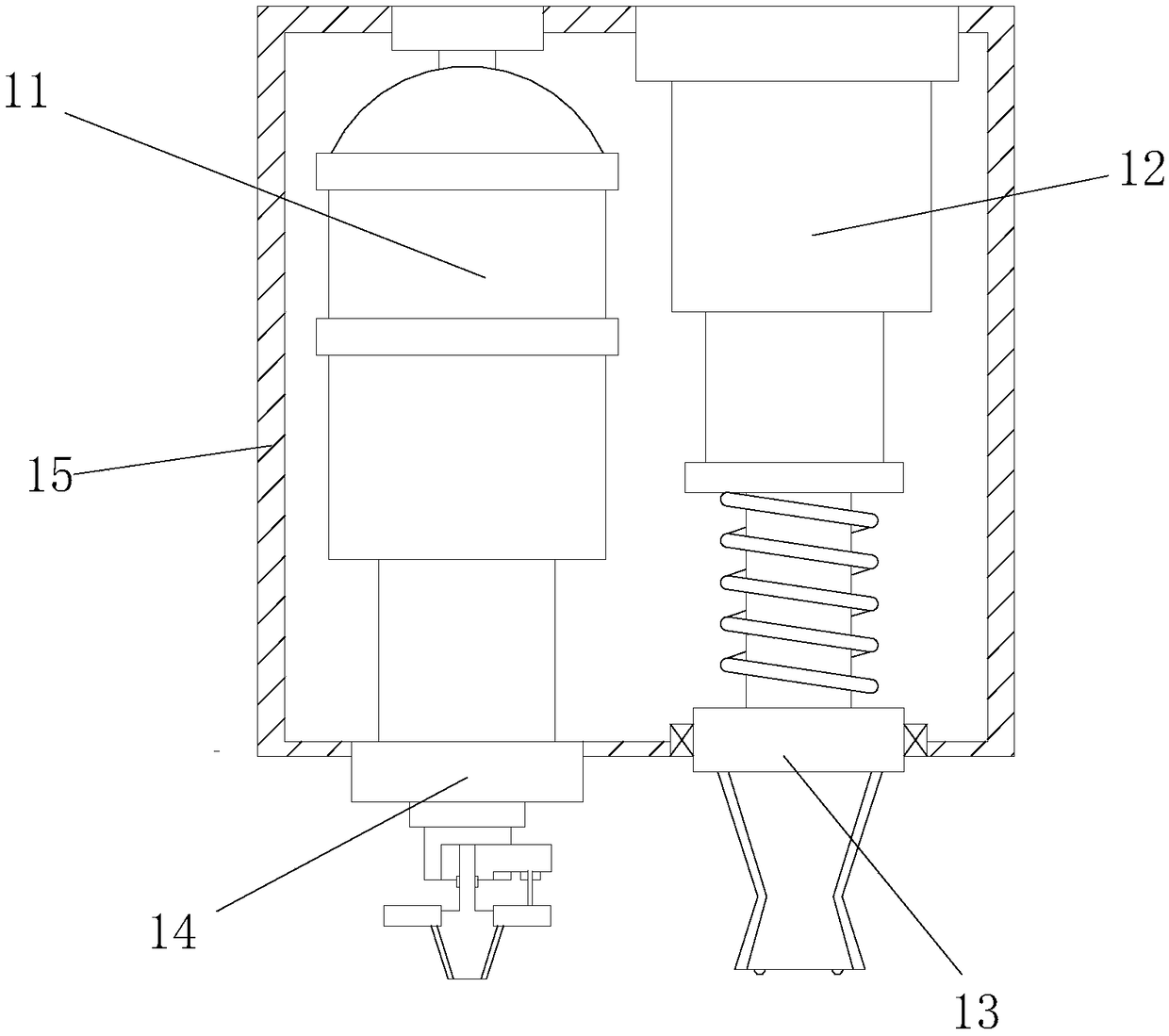

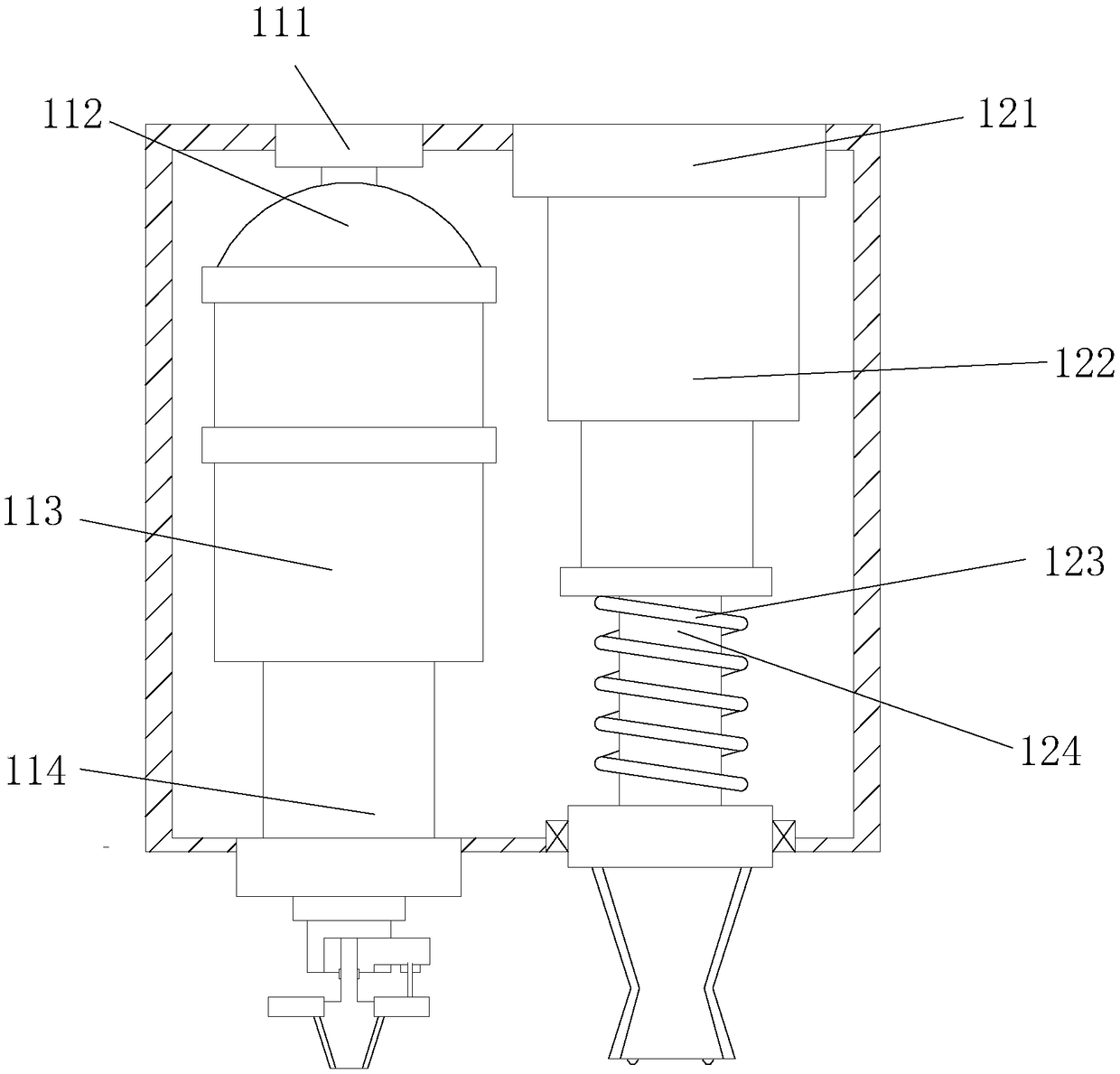

[0027] see Figure 1-Figure 7, the present invention provides a placement machine with replaceable suction nozzles for anti-deviation, the structure of which includes a dispensing head 1, a conveying roller 2, a control body 3, a stopper 4, an anti-deviation track 5, and a detachable control block 6. The dispensing patch head 1 is vertically embedded in the bottom end of the detachable control block 6, the conveying roller 2 is arranged on the left side of the control body 3, the bottom end of the block 4 is welded with the top end of the control body 3, the The detachable control block 6 is horizontally embedded on the anti-deviation track 5, and the dispensing patch head 1 includes a glue spraying control assembly 11, a vacuum suction assembly 12, a suction head mechanism 13, a glue spraying connection mechanism 14, and a housing 15. The glue control assembly 11 is located on the left side of the vacuum adsorption assembly 12. The glue spray control assembly 11 is vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com