Differential pressure sensor

A pressure difference sensor technology, applied in the field of pressure difference sensors, can solve problems such as adverse electrical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

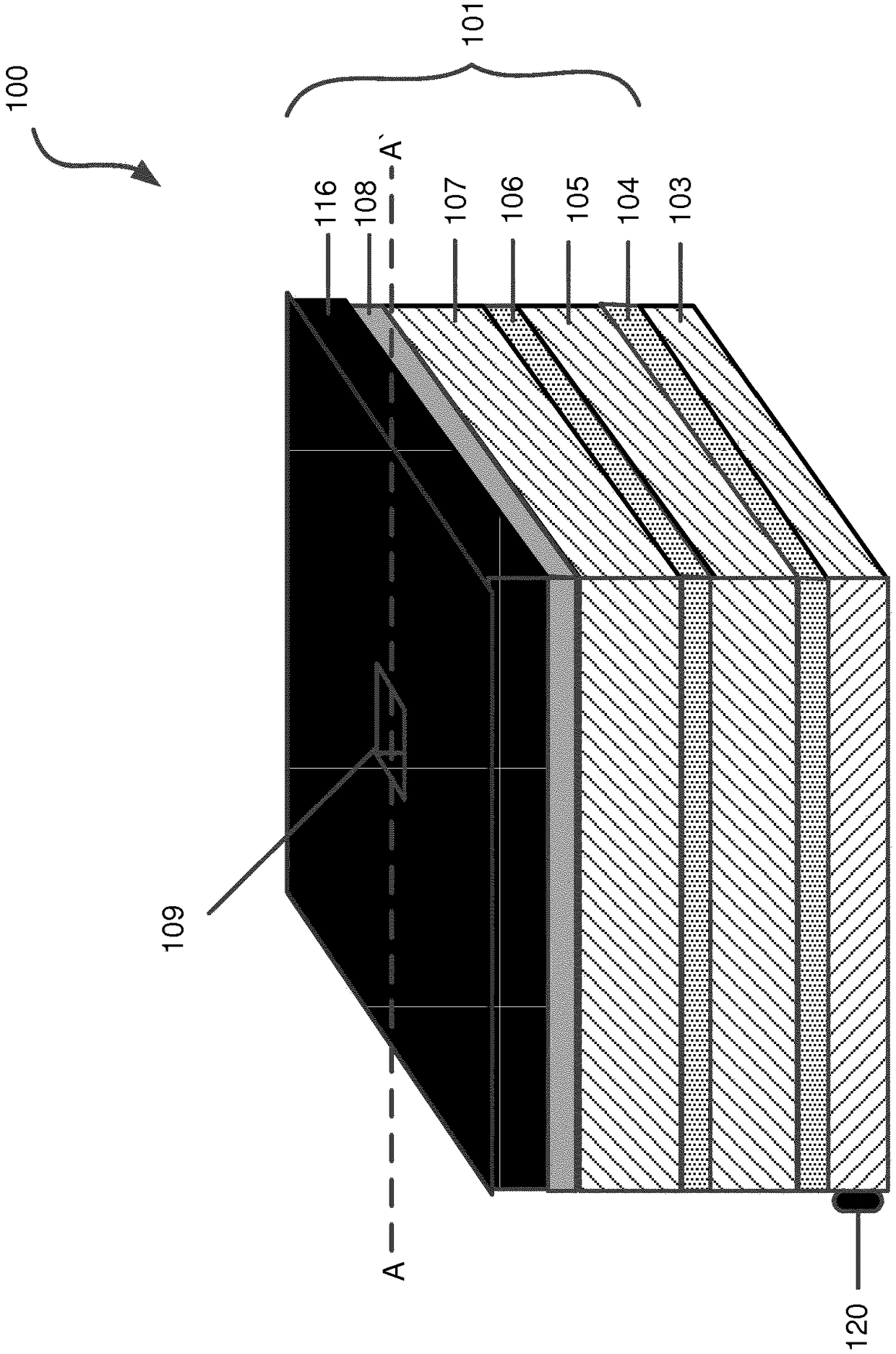

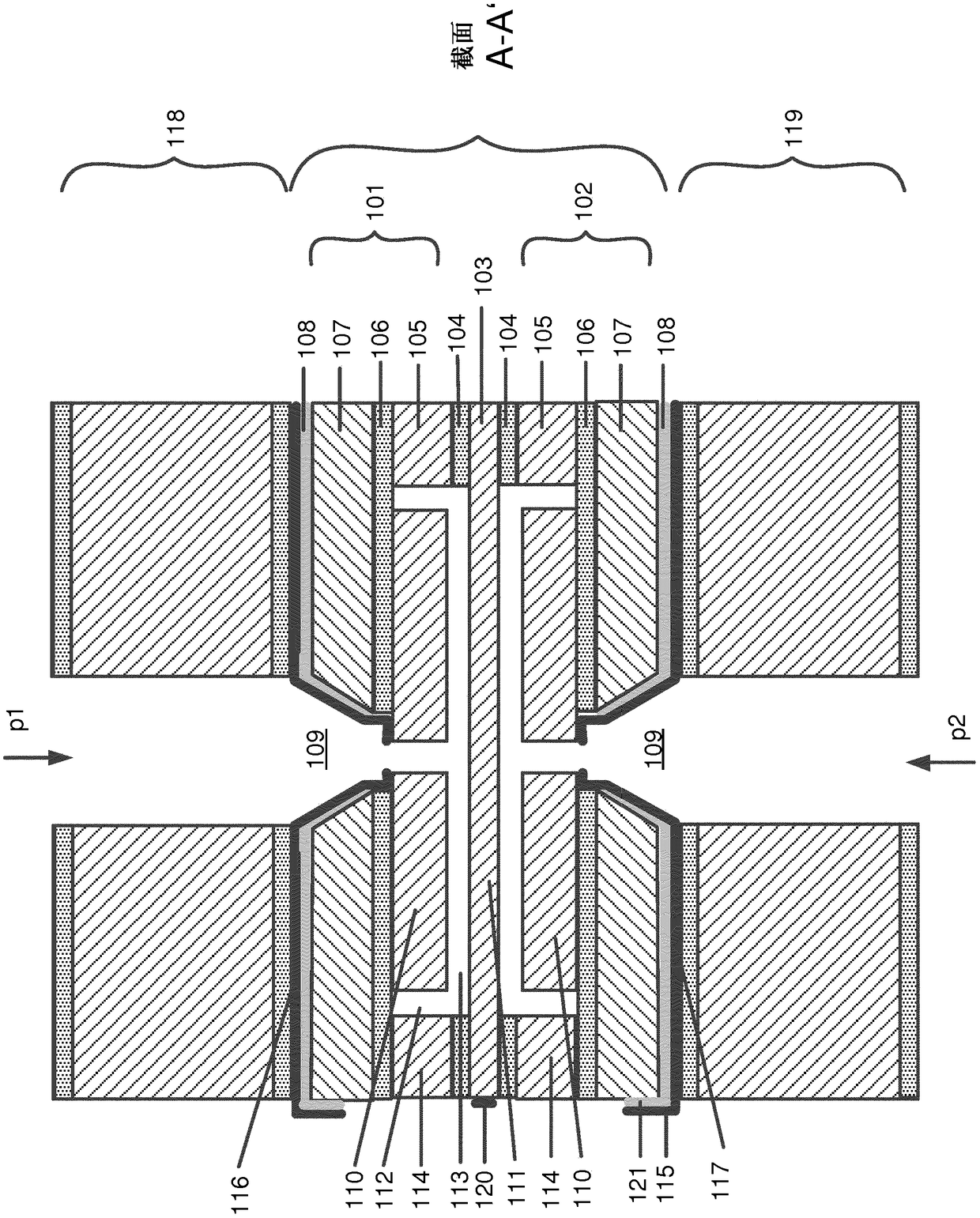

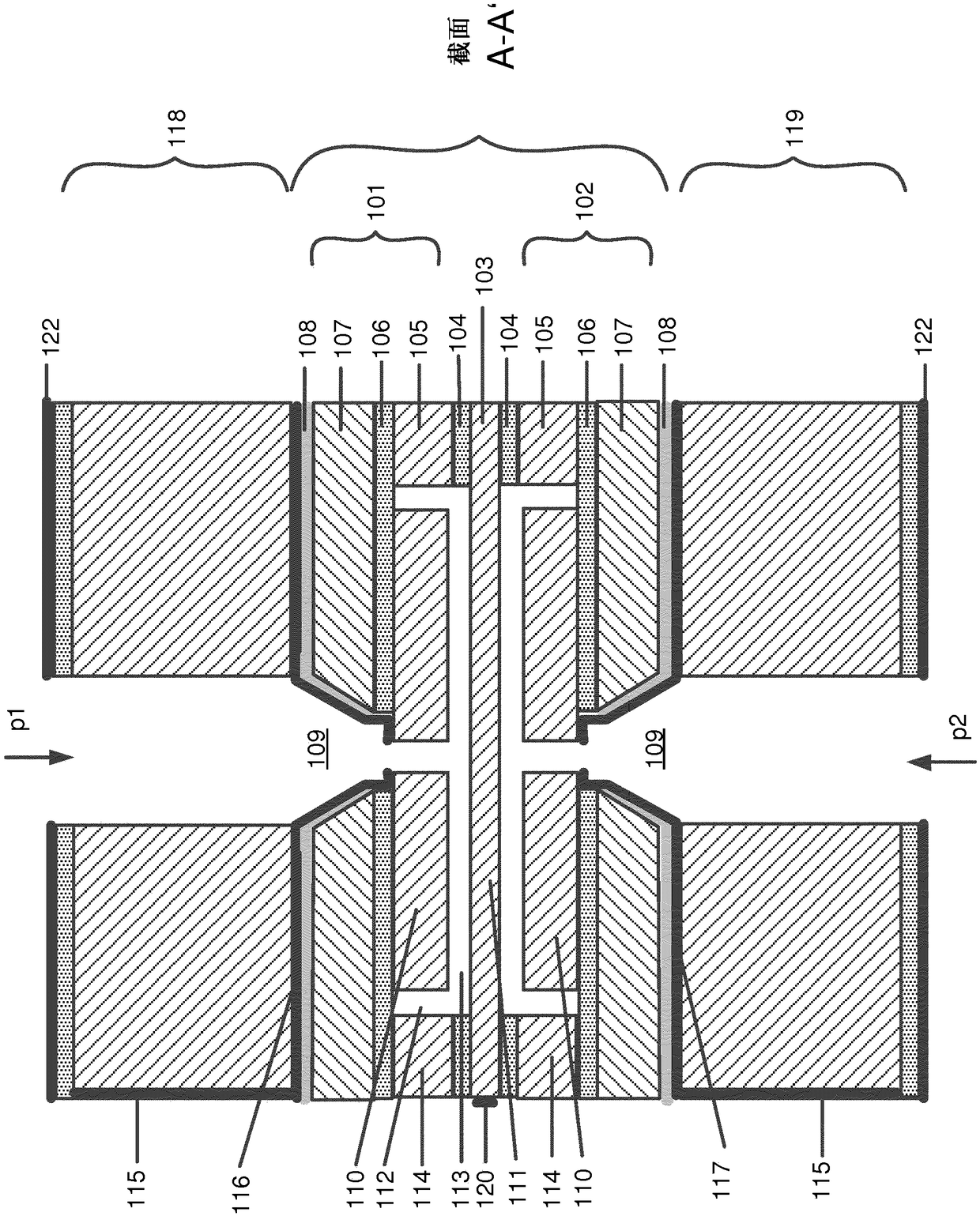

[0034] figure 1 A schematic view of the platform 101 as part of a differential pressure sensor is shown. figure 1 In particular, it is used to indicate the orientation of other figures in a drawing. Figure 2 to Figure 4 A cross-sectional view showing along the figure 1 Layer structure of different forms of embodiments of the differential pressure sensor of the invention in section AA'. The section is essentially in the center through the figure 1 The platforms shown in .

[0035] In principle, the differential pressure sensor of the invention comprises a differential pressure measuring cell 100 substantially implemented from a semiconductor material. Commonly used as semiconductor material is silicon, which is suitably structured or processed by standardized processes, such as are known from the semiconductor industry. The differential pressure measuring cell 100 is bonded via or via a first bonding layer 116 composed of a metallic material to a first reinforcing element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com