Cell culture plate, manufacturing method thereof, and cell patch separating method

A technology of cell culture and manufacturing method, which is applied in the field of cell culture plates, can solve the problems of damaged cell activity and quality, and achieve the effect of ensuring activity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a cell culture plate capable of ensuring the activity and quality of cells when the cells are separated from the cell culture plate.

[0024] A cell culture plate, the cell culture plate includes a base plate and a photodisruption layer formed on the surface of the base plate.

[0025] The material of the substrate is selected from one of transparent plastic and glass, such as polystyrene.

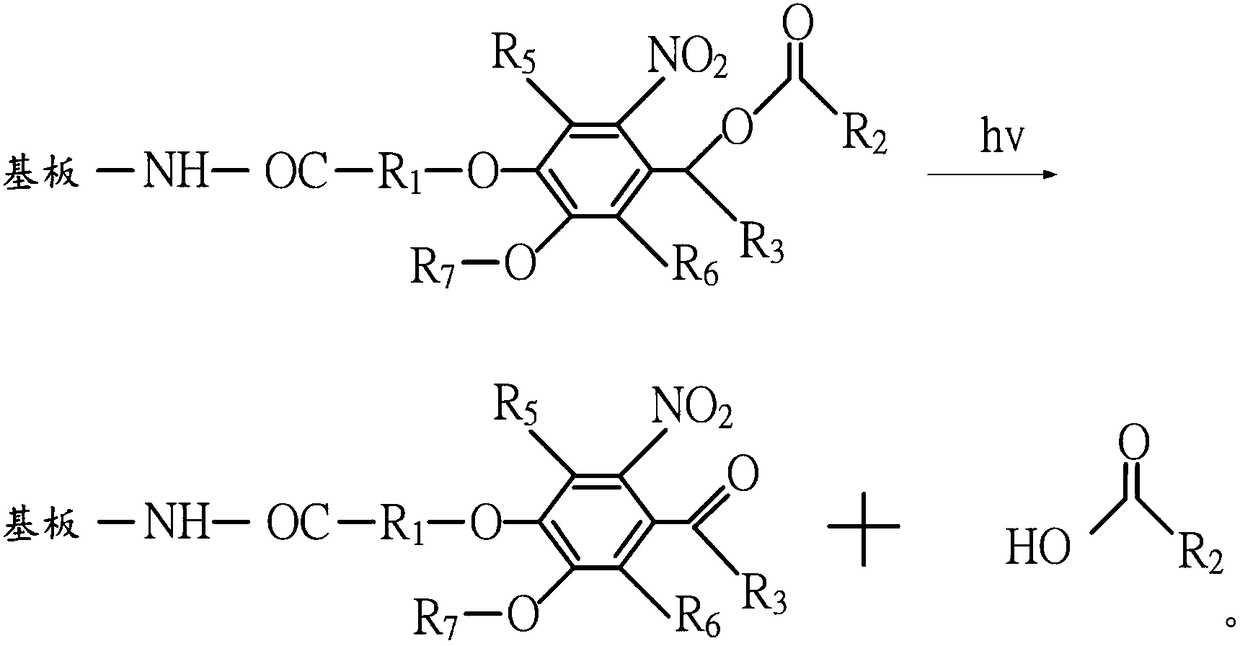

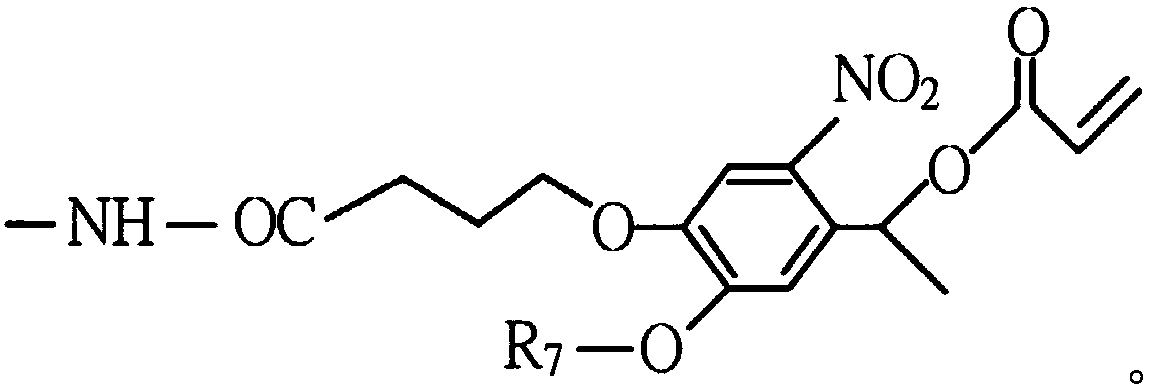

[0026] The photo-breakable layer includes several photo-breakable groups, and the photo-breakable groups are bonded to the surface of the substrate through amido groups. The chemical structural formula of the photocleavage group is Among them, R 1 group and R 3 The group is an alkane group, R 2 The group includes at least an alkane group or an alkene group, R 5 group, R 6 group and R 7 The groups are respectively one of a hydrogen group and an alkane group. Under the light, the ester group on the ortho position of the nitro group in the photocleavage ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap