Rotary valve type pressure pulse generator

A pressure pulse and generator technology, applied in the field of rotary valve pressure pulse generators, can solve the problems of inability to generate effective pressure pulse amplitude, affecting pulse pressure amplitude, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

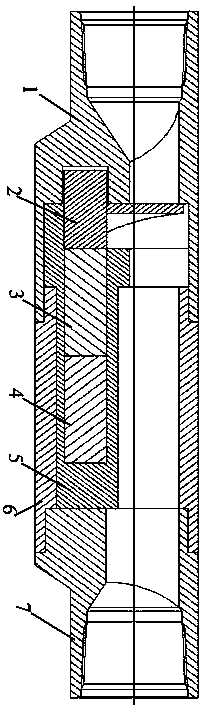

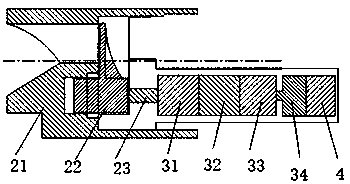

[0025] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

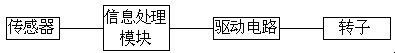

[0026] as attached Figure 1-3 As shown, a rotary valve type pressure pulse generator includes a cylinder structure composed of an upper joint 1, an outer cylinder 6, and a lower joint 7 in sequence. An overflow channel is formed inside the cylinder structure, and a rotary valve 2 is also included. The rotary valve is installed inside the cylinder structure. The rotary valve includes a stator 21, a rotor 22, and a main shaft 23. The stator has a flow hole, and the rotor is fixed on the main shaft. The hole changes the flow area.

[0027] A drive mechanism is also provided inside the cylinder structure, and the power output end of the drive mechanism is connected to the main shaft of the rotary valve. The rotor is connected with a reducer through a main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com