Original cream cheese and preparation method thereof

A cream cheese and whipping cream technology, applied in the cheese field, can solve the problems that the processed cream cheese is difficult to reach the original cream cheese, the original cream cheese production process is complicated, and the production equipment is multiple, and the production cycle is shortened, the taste is fine and the taste is better. Texture, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

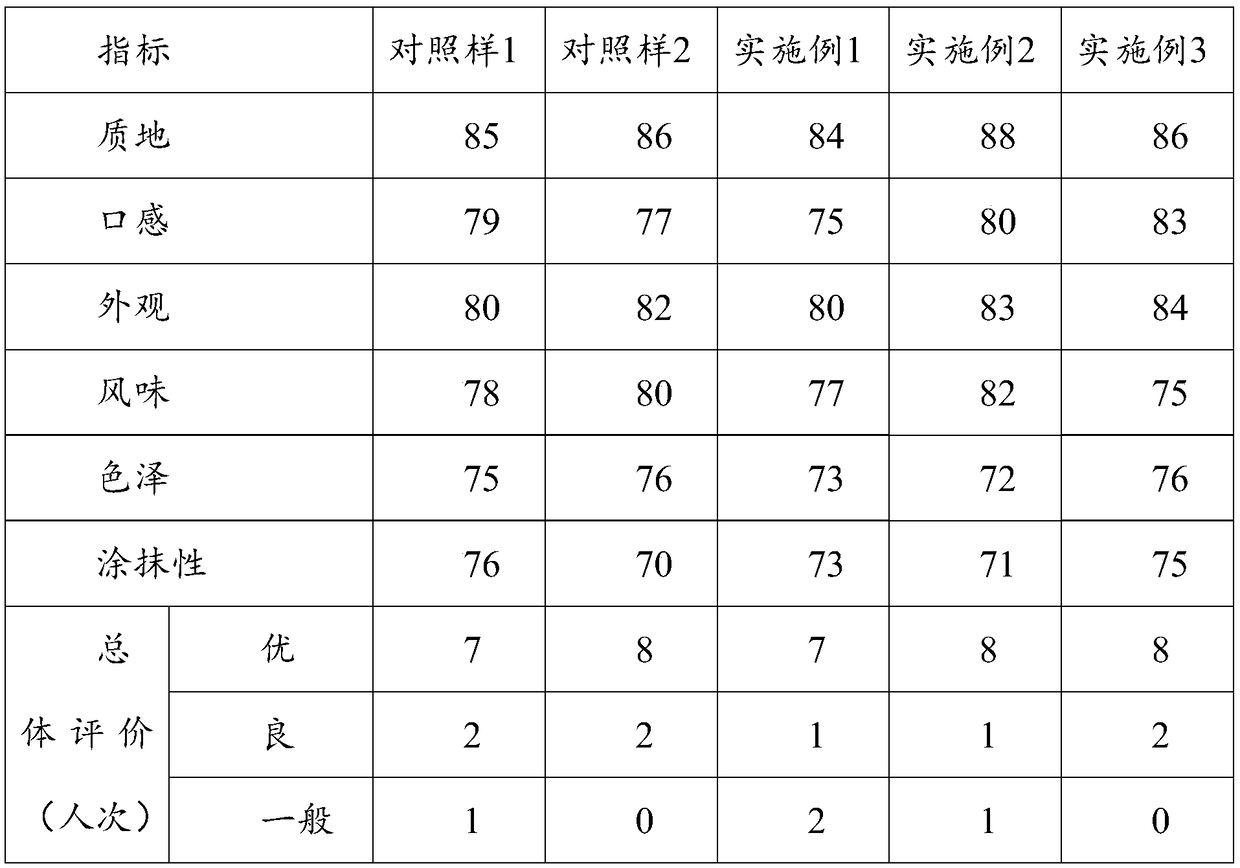

Examples

preparation example Construction

[0025] In another specific embodiment, a method for preparing original cream cheese is provided, the method comprising the following steps:

[0026] ① Preheat and then homogenize, heat the butter and homogenize;

[0027] ②Mix the materials, heat the materials obtained in step ①, add Greek yogurt, milk protein powder, cream, salt, stabilizer, keep warm and stir for 3-10 minutes, preferably, the milk protein powder uses milk protein content ≥ 55% whole milk protein powder.

[0028] ③ Sterilization, heat up the material obtained in step ② first and then keep it warm; the sterilization conditions, such as pasteurization.

[0029] ④ aseptic homogenization, step ③ aseptic homogenization of the obtained material while hot;

[0030] ⑤ Aseptic filling and cooling, the material obtained in step ④ canned, cooled at room temperature, and refrigerated, wherein the refrigerated temperature is 4-6 ° C, after aseptic homogenization and aseptic filling while hot, carry out at room temperatur...

Embodiment 1

[0037] An original cream cheese prepared from the following raw materials: 55% Greek yogurt, 2% butter, 1% milk protein powder, 20% cream, 0.3% table salt, 0.1% stabilizer, Wherein the Greek yogurt is fermented milk obtained by filtering out whey after fermenting raw milk.

[0038] The preparation method of the processed cheese is as follows: first preheating, then homogenizing → mixing → sterilizing → aseptic homogenizing → aseptic filling → cooling, and the specific steps are as follows:

[0039] ① Preheat and then homogenize, heat the butter to 40°C, and the homogenization pressure is 21Mpa;

[0040] ②Mix the ingredients. Heat the material obtained in step ① to 65°C, add Greek yogurt, milk protein powder, cream, salt, and stabilizer, and keep stirring for 3 minutes.

[0041] ③ Sterilize, heat up the material obtained in step ② to 80°C, and keep it warm for 10 minutes.

[0042] 4. Aseptic homogenization, step 3. The obtained material is aseptically homogenized under the co...

Embodiment 2

[0045] An original cream cheese prepared from the following raw materials: 35% Greek yogurt, 22% butter, 8% milk protein powder, 10% cream, 0.8% salt, 0.7% stabilizer, Wherein the Greek yogurt is fermented milk obtained by filtering out whey after fermenting raw milk.

[0046] The preparation method of the processed cheese is as follows: first preheating, then homogenizing → mixing → sterilizing → aseptic homogenizing → aseptic filling → cooling, and the specific steps are as follows:

[0047] ① Preheat and then homogenize, heat the butter to 65°C, and the homogenization pressure is 19Mpa;

[0048] ②Mix the ingredients, heat the materials obtained in step ① to 40°C, add Greek yogurt, milk protein powder, cream, salt, and stabilizer, and keep stirring for 10 minutes.

[0049] ③ Sterilize, heat up the material obtained in step ② to 95°C and keep it warm for 3 minutes.

[0050] 4. Aseptic homogenization, step 3. The obtained material is aseptically homogenized under 18Mpa conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com