Automobile automatic fire extinguishing system

An automatic fire extinguishing system and automobile technology, which is applied in fire rescue and other fields, can solve the problems of easy loosening and falling off of fire extinguishers, damaged insulating rubber, unstable performance, etc., and achieves simple and easy installation, slow burning speed of large fires, small and compact shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the specific embodiments of the present invention are only for the purpose of describing the technical solution more clearly, but not as a limitation of the protection scope of the present invention.

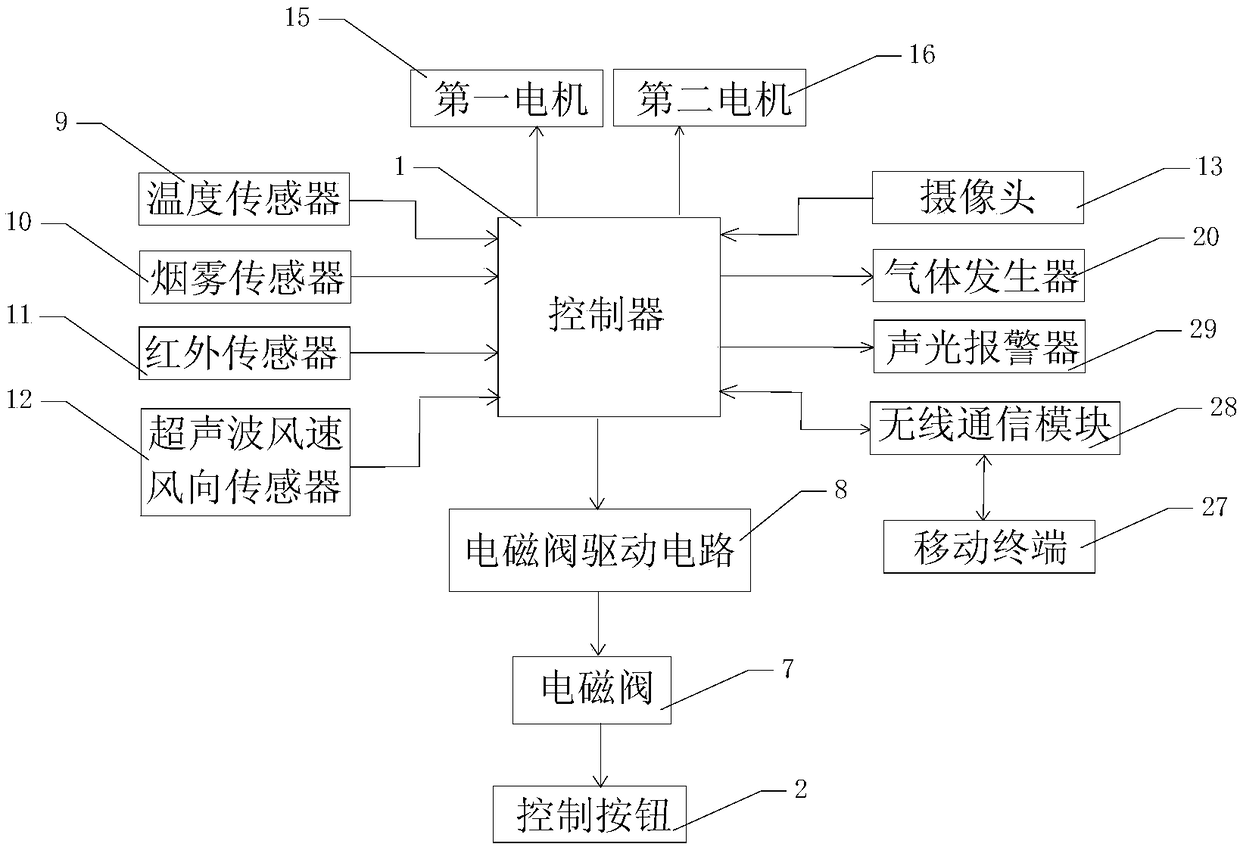

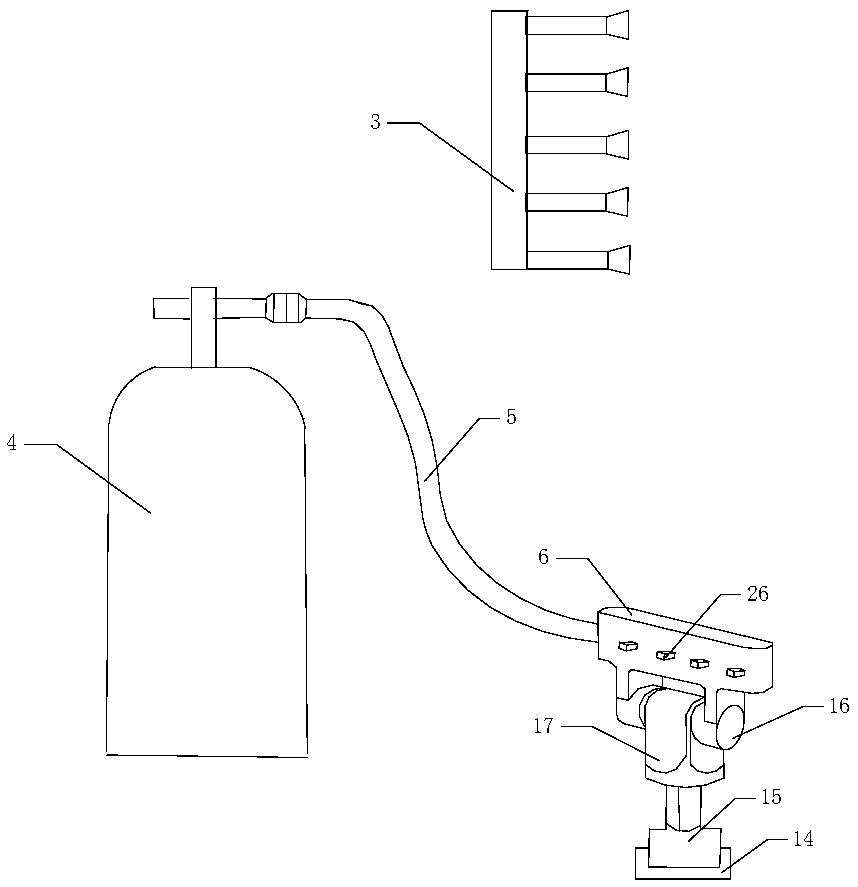

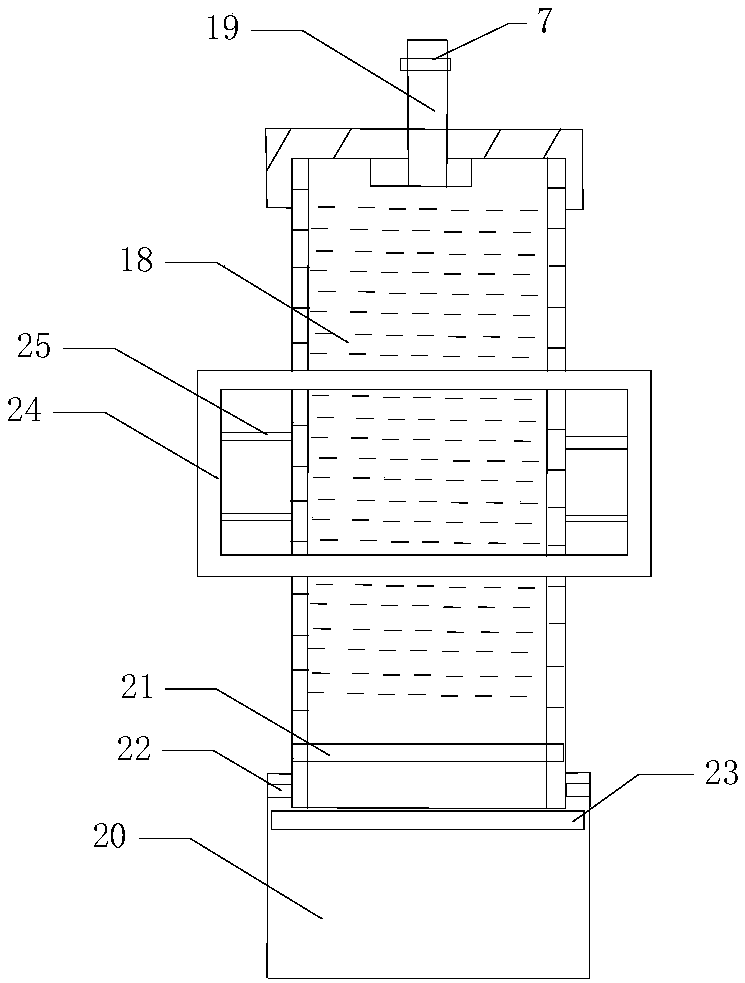

[0028] see Figure 1-3 , an automobile automatic fire extinguishing system, comprising a controller 1, a control button 2 and several fire extinguishing assemblies, the controller 1 and the control button 2 are arranged in the cab, and the fire extinguishing assemblies are respectively arranged at a plurality of fire positions to be detected inside the car body , the fire extinguishing assembly includes a fire detection sensor 3, a fire extinguisher 4, a metal pipe 5 and a nozzle 6, the fire detection sensor 3 is electrically connected to the controller 1, and the fire detection sensor 3 is used to generate an alarm signal from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com