Branchial filter

A technology of filters and filter chambers, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve problems such as difficult cleaning, long working hours, troubles in user use and maintenance, etc., and achieve simple and convenient operation and removal of impurities Dirty effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0024] The problem to be solved by the present invention is to provide a gill filter which can efficiently filter solids in water and works stably.

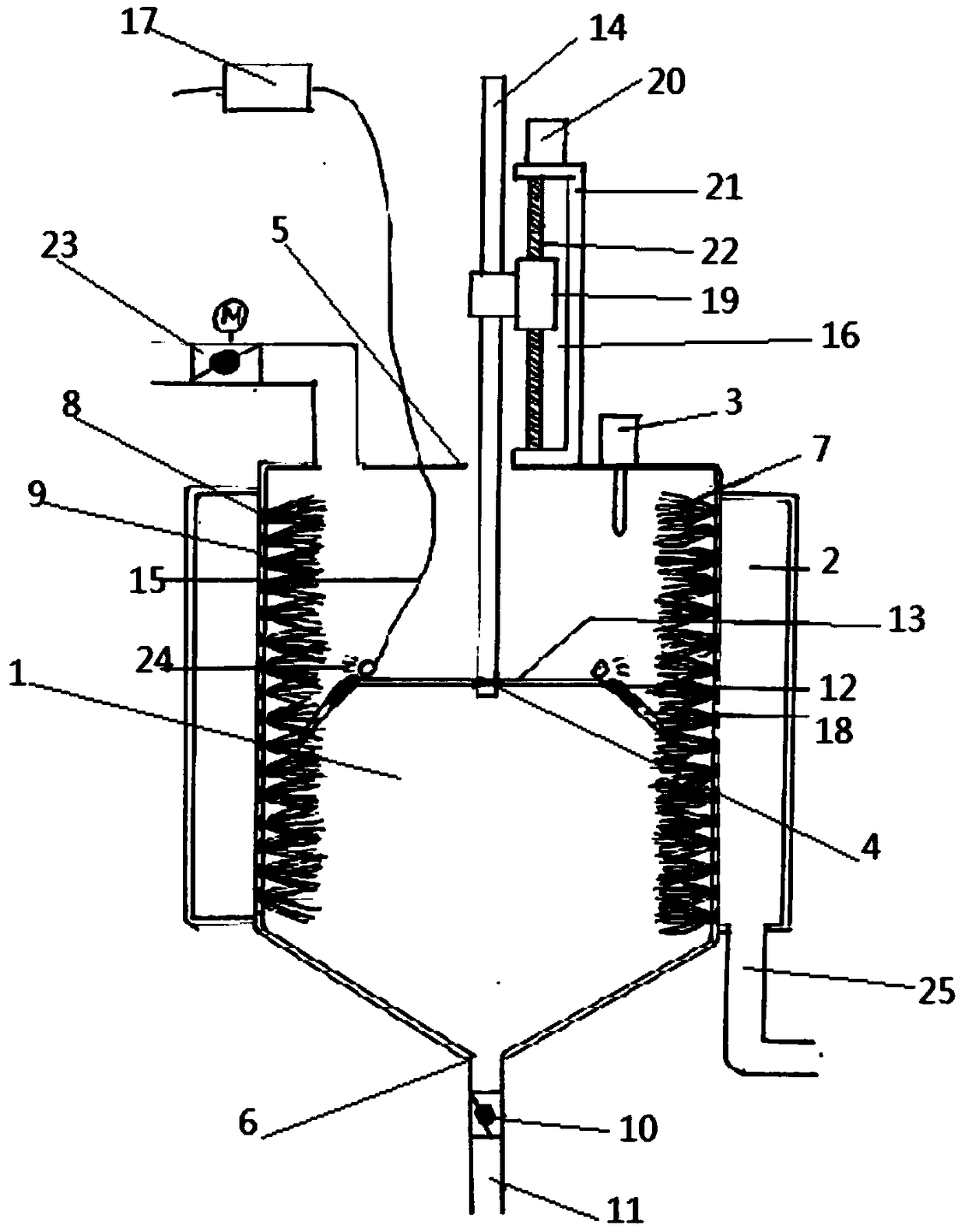

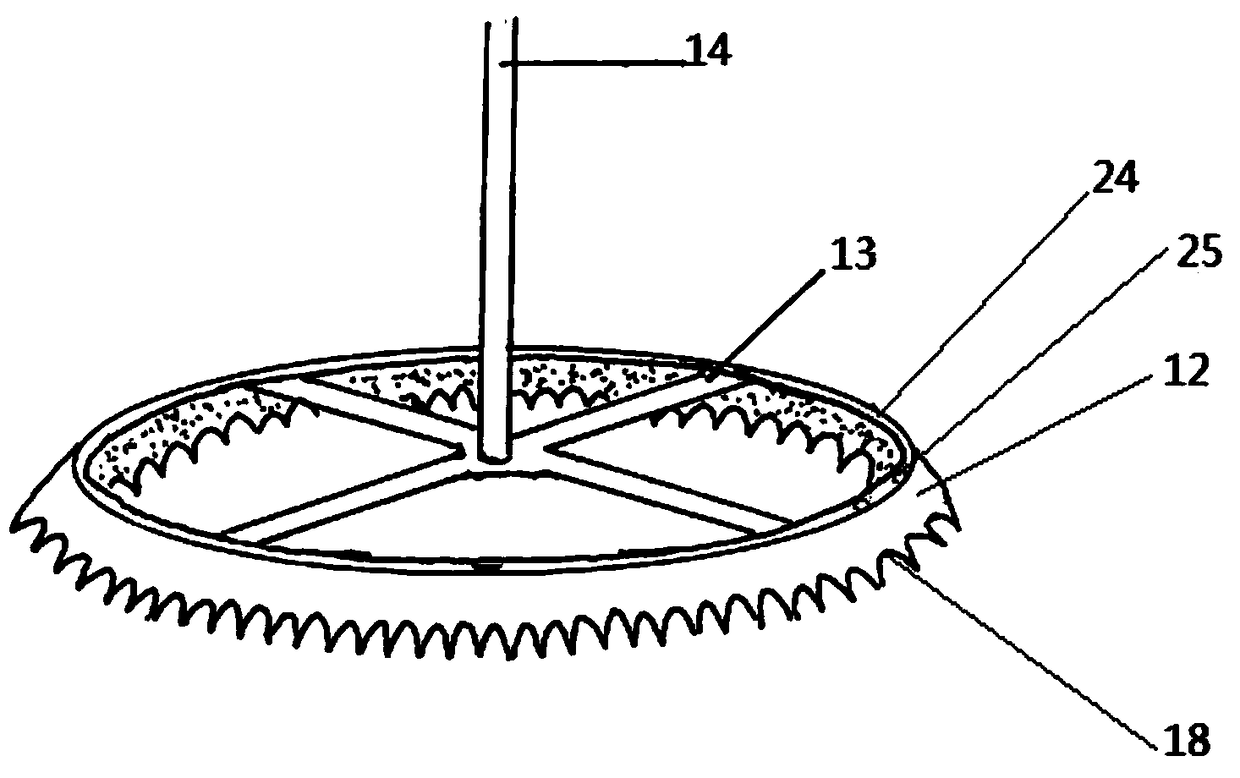

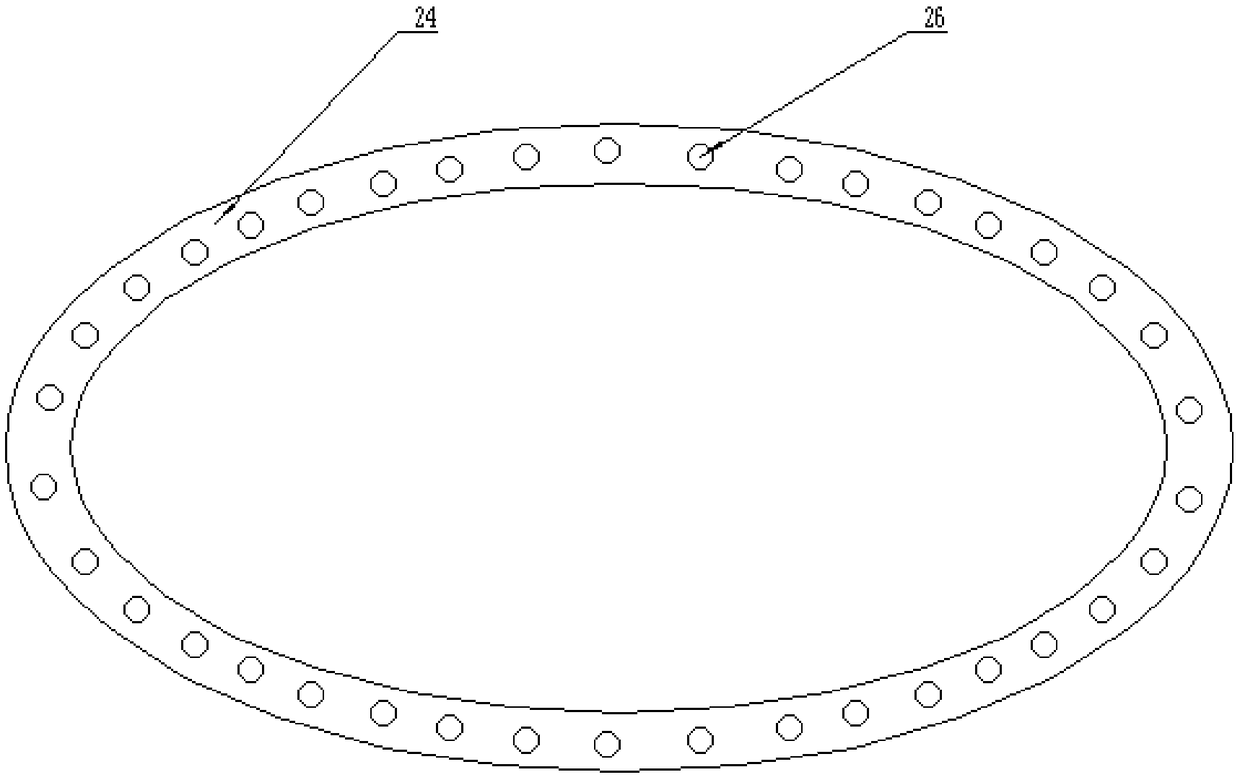

[0025] Such as figure 1 As shown, in order to ensure that the gill filter works stably and reliably and efficiently filters solids in water during use, the present invention relates to a gill filter, including:

[0026] Filter cavity 1, jacket cavity 2, liquid level gauge 3, automatic cleaning device 4;

[0027] The filter cavity 1 is in a barrel-shaped structure; the upper end of the filter cavity 1 is open, and the lower end of the filter cavity 1 is inverted tapered; the outer casing 2 is wrapped around the filter cavity 1 to form a cavity structure for collecting The water flow flowing out from the filter cavity 1; the liquid level gauge 3 is fixed on the upper right end of the filter cavity 1 for measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com