Rice polishing device

A polishing device and rice technology, applied in application, grain finishing, grain germ removal, etc., can solve the problem that rice cannot be sieved cleanly, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

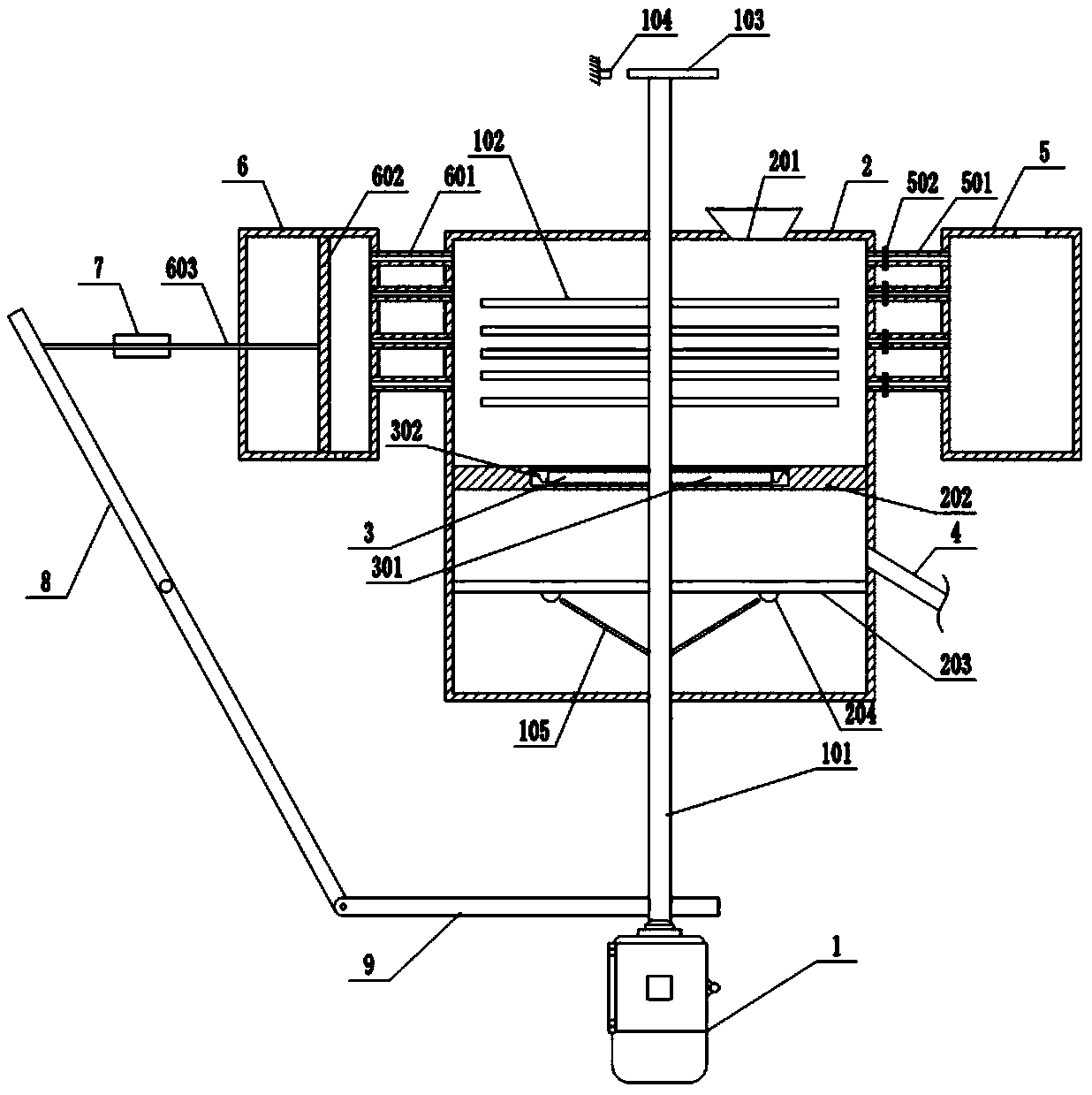

[0024] Polishing device for rice, such as figure 1 As shown, including the frame, the frame is fixed with an air box 6, an operation box 2 and a water tank 5 successively from left to right, and a drive member fixed on the frame is provided directly below the operation box 2. In this embodiment, the drive The component is a motor 1, the output shaft of the motor 1 is coaxially connected with a rotating shaft 101 vertically penetrating through the operation box 2, the top of the rotating shaft 101 is coaxially connected with a cam 103, and the frame is fixedly connected with a button switch 104 that can be squeezed by the cam 103 .

[0025] The top wall of the operation box 2 is provided with a power supply (not shown in the figure), the power supply in the present embodiment is a dry battery pack, and the operation box 2 is welded with a handle that can divide the operation box 2 into the top of the operation box 2 and the bottom of the operation box 2. Partition plate 202 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com