Caked lime recycling and reusing device for building construction

A construction and agglomeration technology, which is applied in the direction of solid separation, sieve, grid, etc., can solve the problems of easy agglomeration and hardening, poor practicability, and inability to use, etc., and achieves good crushing effect, strong practicability, Effect of improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

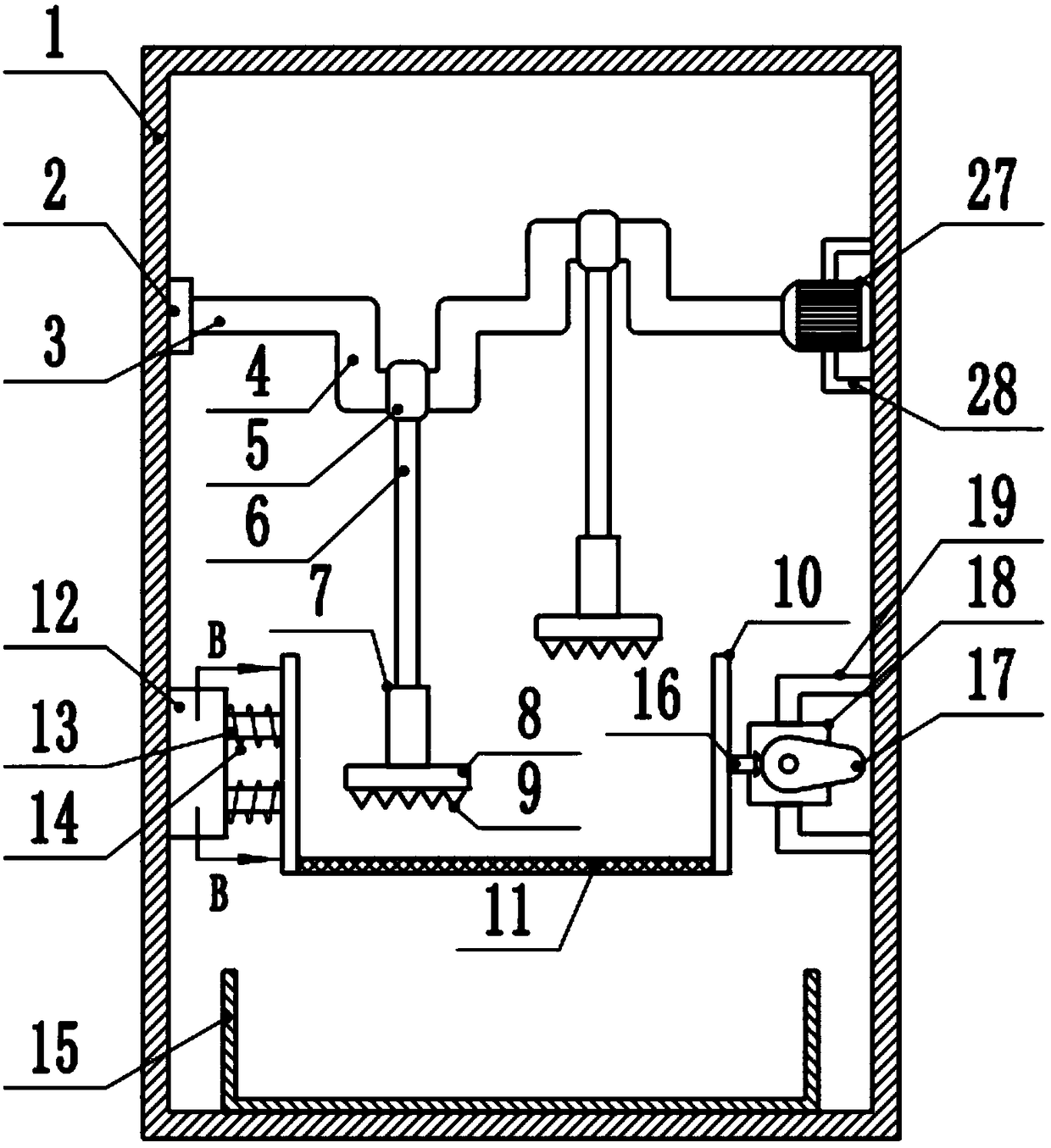

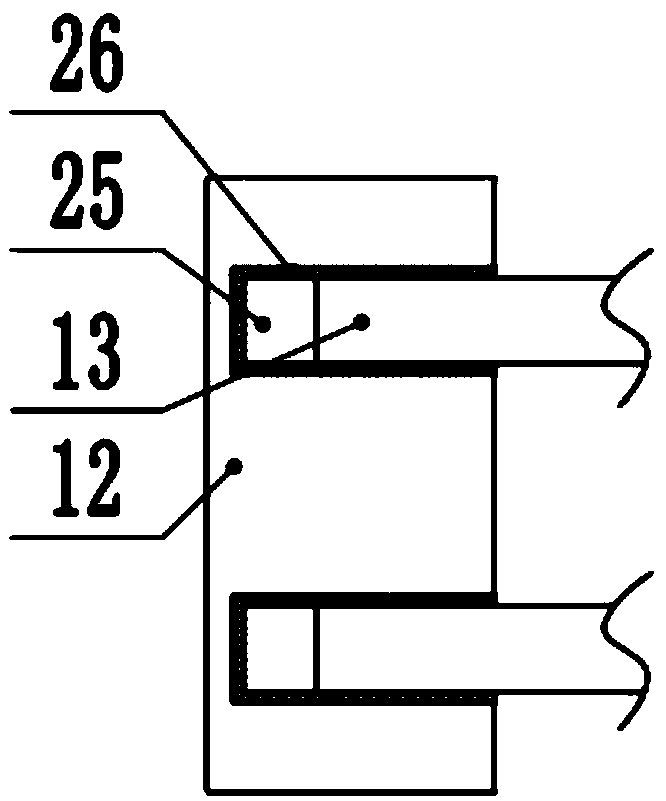

[0023] see Figure 1-2 , a kind of agglomerated lime recycling device for building construction, comprising a processing box 1, a shaft sleeve 2 is fixedly connected to the upper left side of the processing box 1, and a rotating rod 3 is slidably connected to the middle of the right side surface of the shaft sleeve 2, The right end of the rotary rod 3 is connected with a rotary motor 27, and the motor 27 is started, thereby driving the rotary rod 3 to rotate, and then driving the protrusion 4 to rotate, so that the two crushing teeth 9 are alternately reciprocated up and down, and the upper and lower sides of the rotary motor 27 are fixedly connected. There is a second motor fixing frame 28, the right end of the second motor fixing frame 28 is fixedly connected to the top of the inner right side of the processing box 1, and the upper and lower sides of the left and right sides of the middle part of the rotating rod 3 are fixedly connected with protrusions 4 respectively. 4. Th...

Embodiment 2

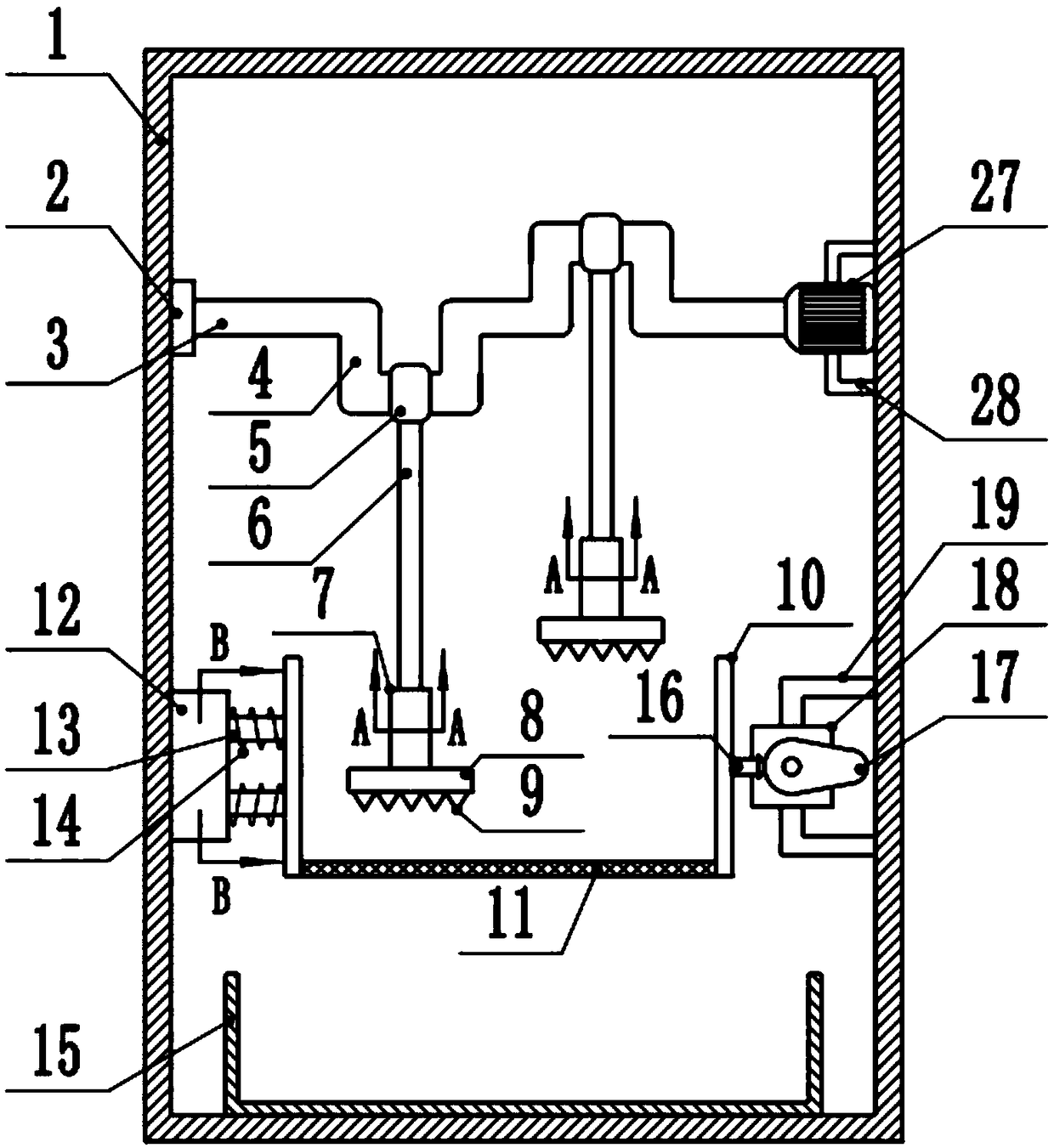

[0026] see Figure 3-4 The difference between the second embodiment and the first embodiment is that a slide bar 20 is fixedly connected to the bottom of the left and right sides of the inner wall above the connecting seat 7, and the lower end of the slide bar 20 is fixedly connected to a stopper 23. The surface is contact-connected with a slider 21, and the lower surface of the slider 21 is fixedly connected with a second spring 22. The lower end of the slider 20 passes through the middle of the second spring 22 and is connected with the second spring 22 in contact. The number of blocks 21 is two, and the inner surfaces of the two sliders 21 are fixedly connected with a fixed connecting rod 24. The middle part of the upper surface of the fixed connecting rod 24 is fixedly connected with the lower end of the connecting rod 6. When the crushing teeth 9 come into contact with the agglomerated lime, and When crushing, make the slider 21 slide upwards on the surface of the slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com