Mechanical ceramic-pulverizing device

A grinding and ceramic technology, applied in grain processing and other directions, can solve the problem of not being able to automatically adjust the torque of mechanical grinding, and achieve the effect of fast rotation speed and increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

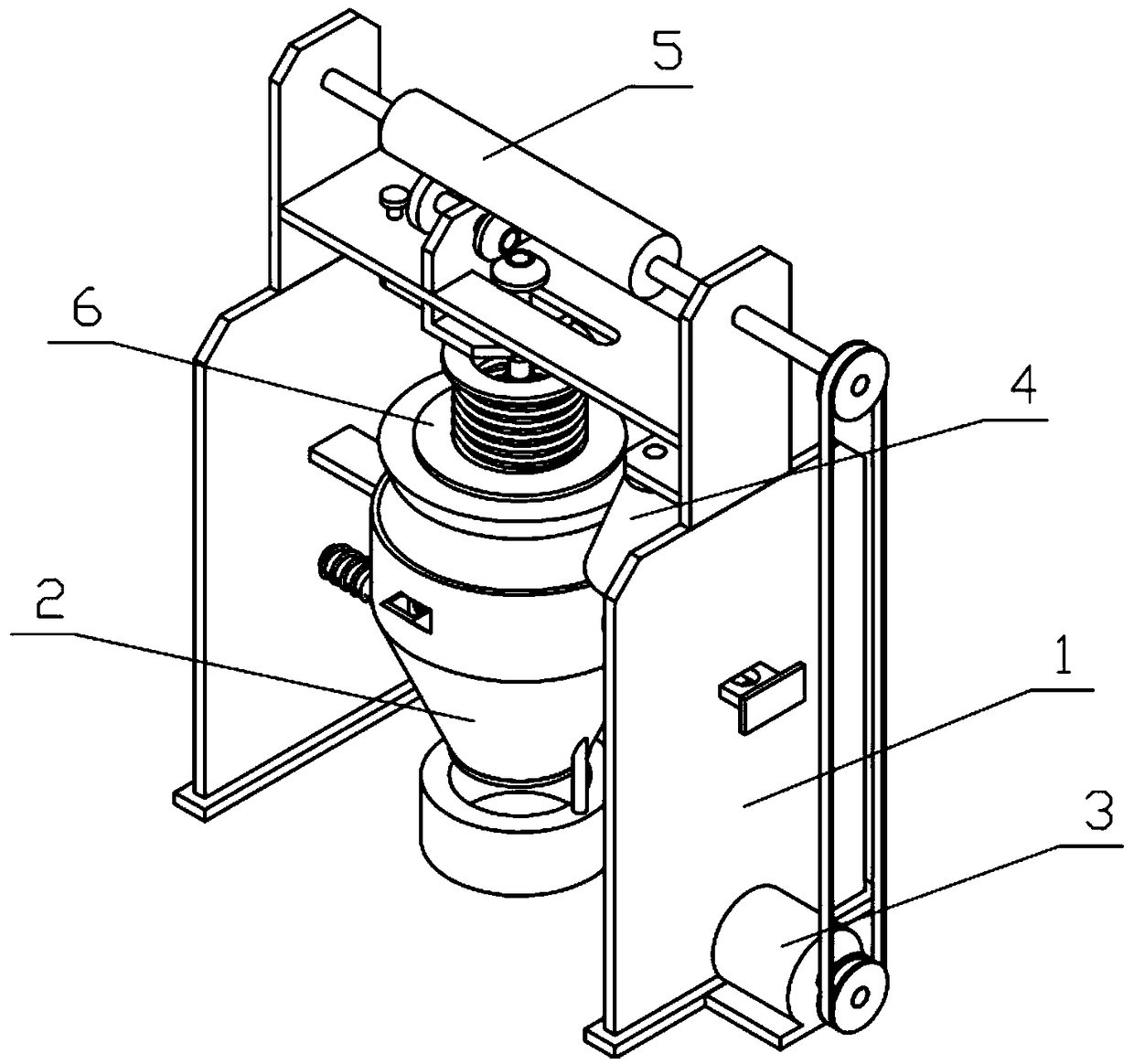

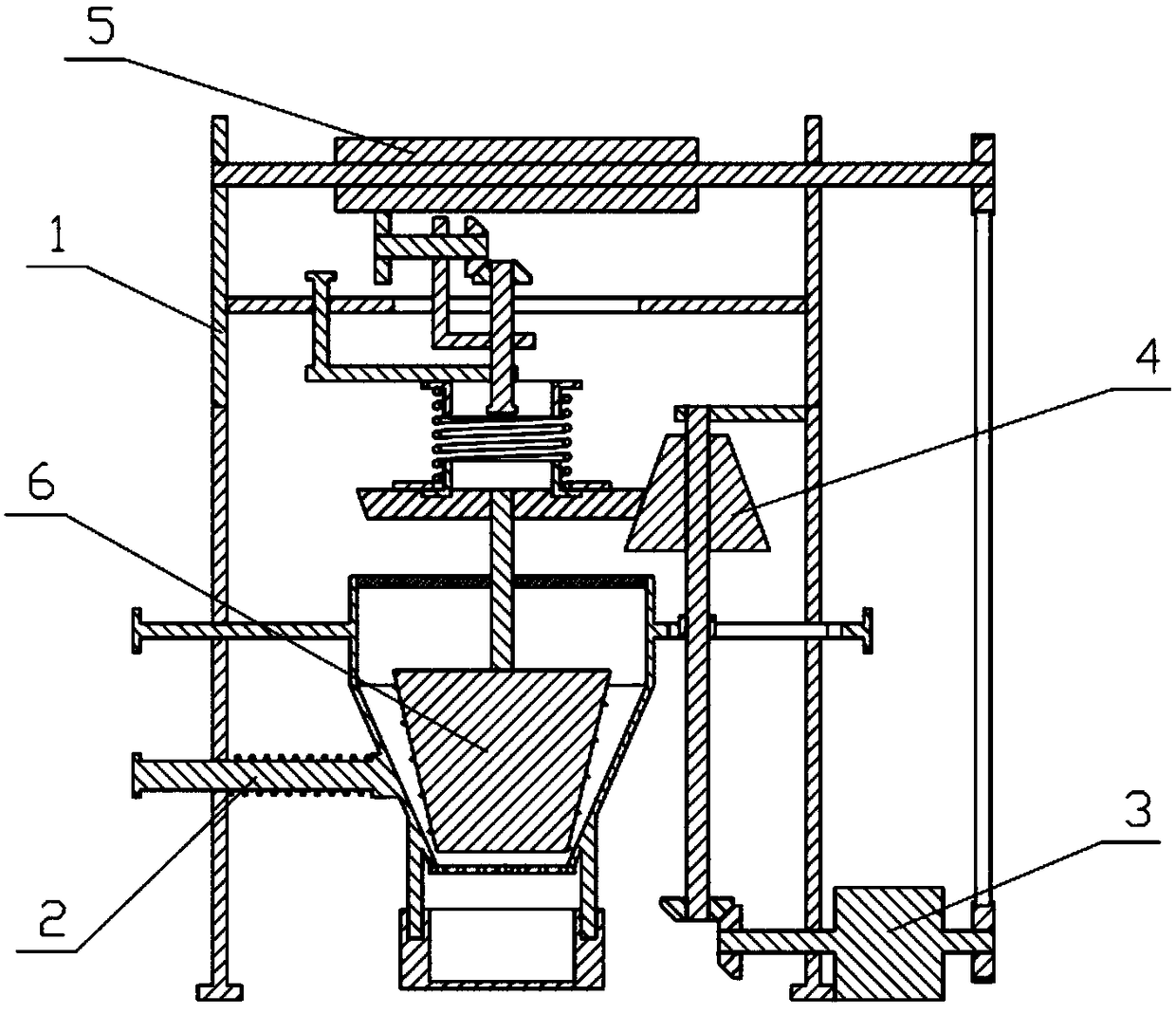

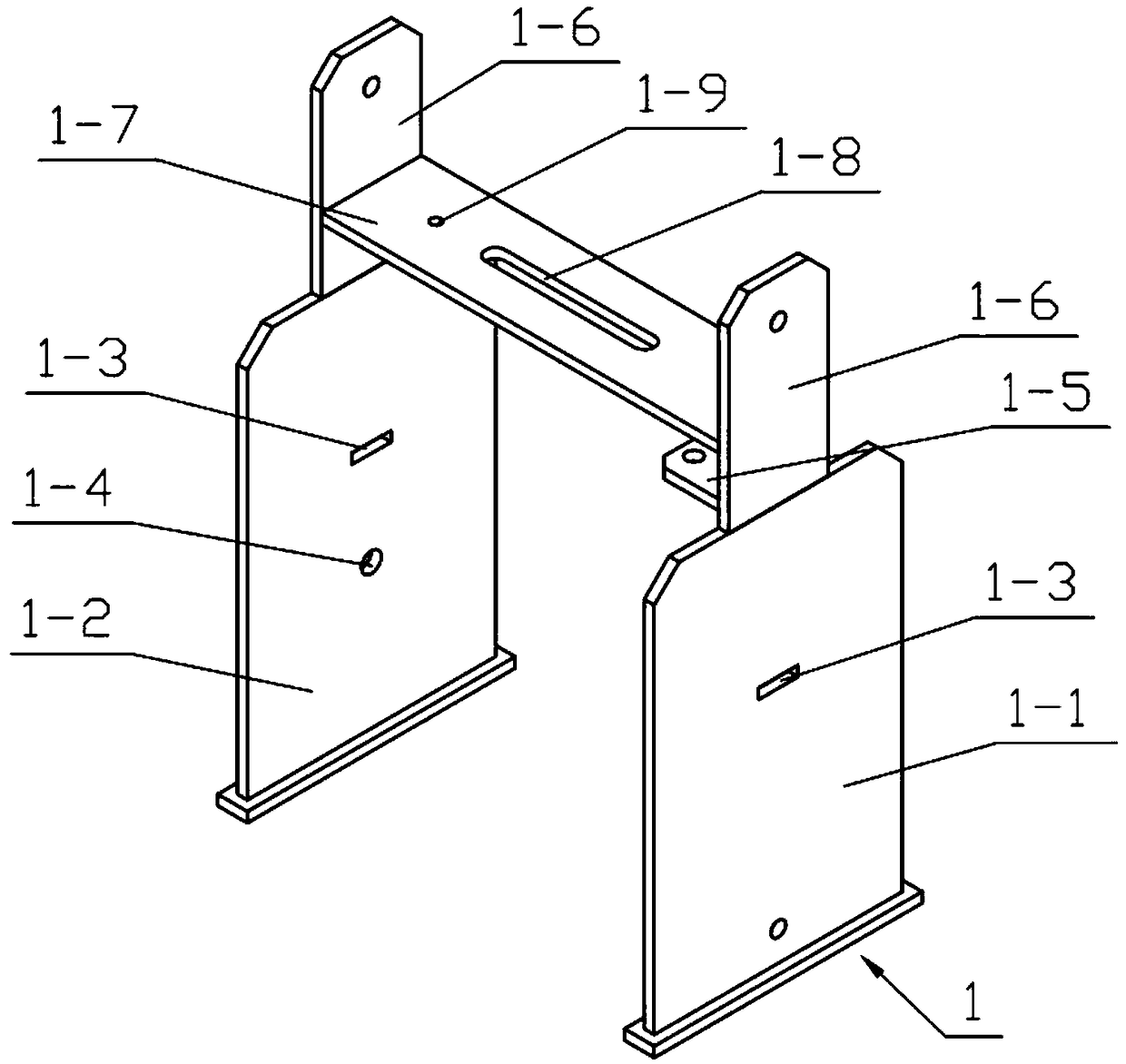

[0031] Combine below Figure 1-10 Describe this embodiment, a ceramic mechanical grinding device, including the whole machine bracket 1, the grinding cylinder 2, the power mechanism 3, the feedback mechanism 4, the transmission mechanism 5 and the grinding mechanism 6, and the feedback mechanism can be driven by the power mechanism 3 at the same time 4 and the transmission mechanism 5 rotate at the same time, and the transmission mechanism 5 pushes the milling mechanism 6 to move downward through the horizontal transmission of the thread, and the compression spring II set on the milling mechanism 6 produces a certain extrusion force on the milling wheel 6-16 , the grinding wheel 6-16 is driven by the conical friction wheel II 6-14 to rotate in the grinding cone 2-2, and the taper of the grinding wheel 6-16 is smaller than the taper of the grinding cone 2-2 , the upper diameter of the milling wheel 6-16 and the milling cone 2-2 is greater than the lower diameter, and the millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com