Vacuum pump

a vacuum pump and pump body technology, applied in the field of vacuum pumps, can solve the problems of high cost and achieve the effect of reducing the cost of the pump, facilitating the rotation of the shaft, and contributing to the cost-effectiveness and compactness of the inventive vacuum pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

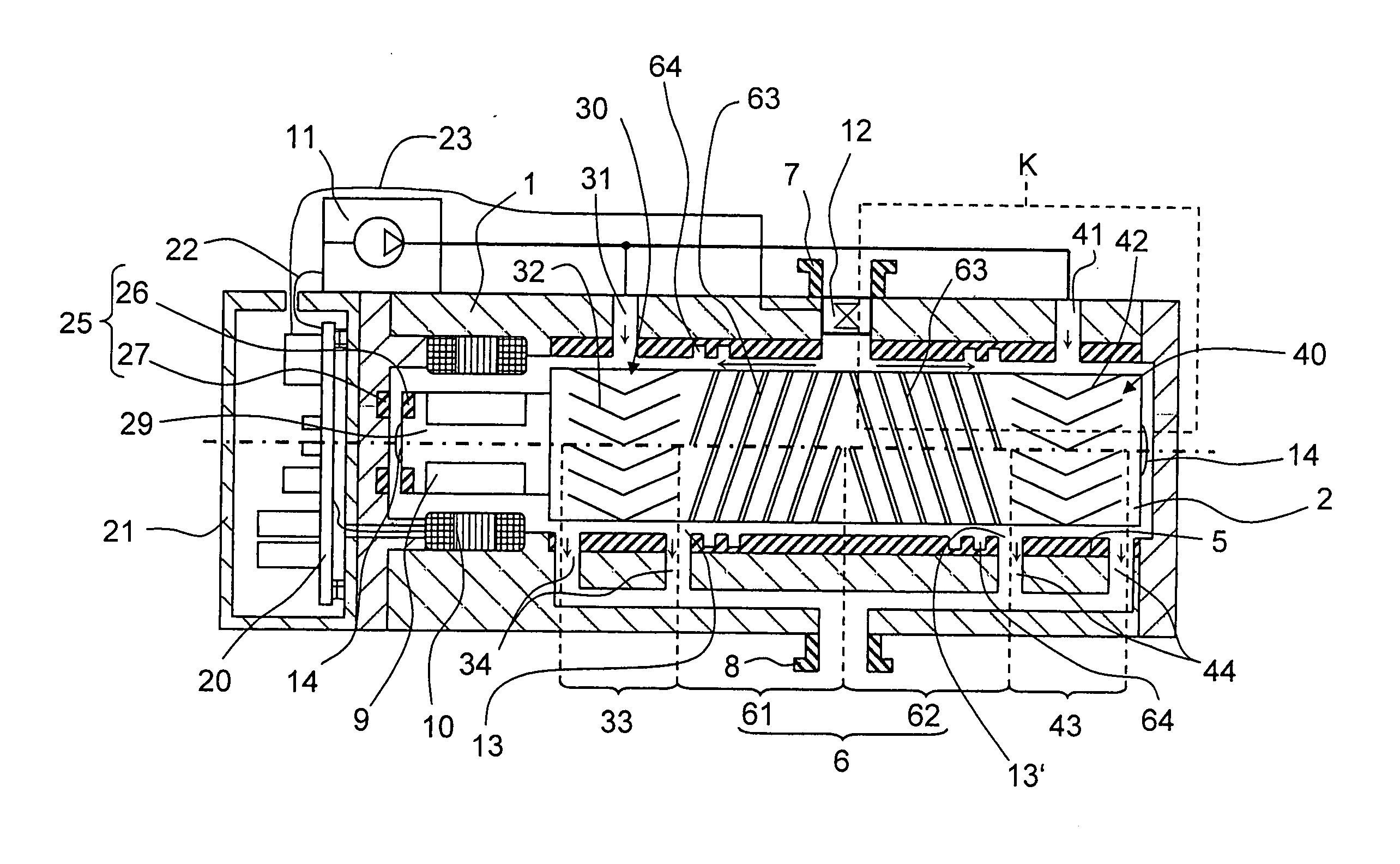

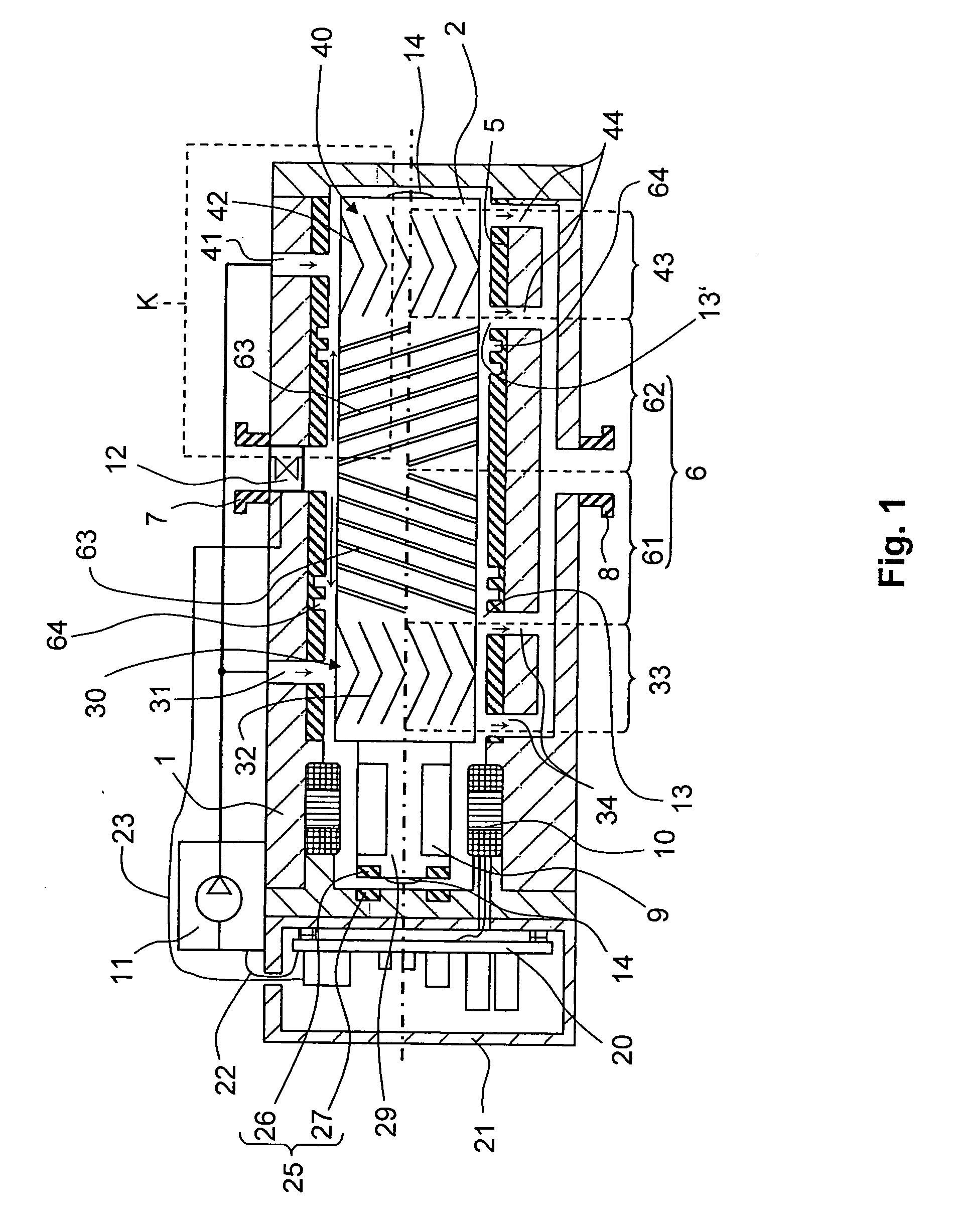

[0021]A vacuum pump according to the present invention, which is shown in FIG. 1, has a housing 1 having a gas inlet 7 and a gas outlet 8. Inside the housing 1, there is arranged a cylinder 5 in which a shaft 2 is rotatably supported. At its opposite ends, the shaft is supported by two gas bearings 30 and 40, respectively.

[0022]The first gas bearing 30 includes a gas inlet 31, a shaft-side bearing structure 32 and a bearing gas outlet 34. The bearing structure 32 forms a bearing section 33 extending in the shaft axial direction.

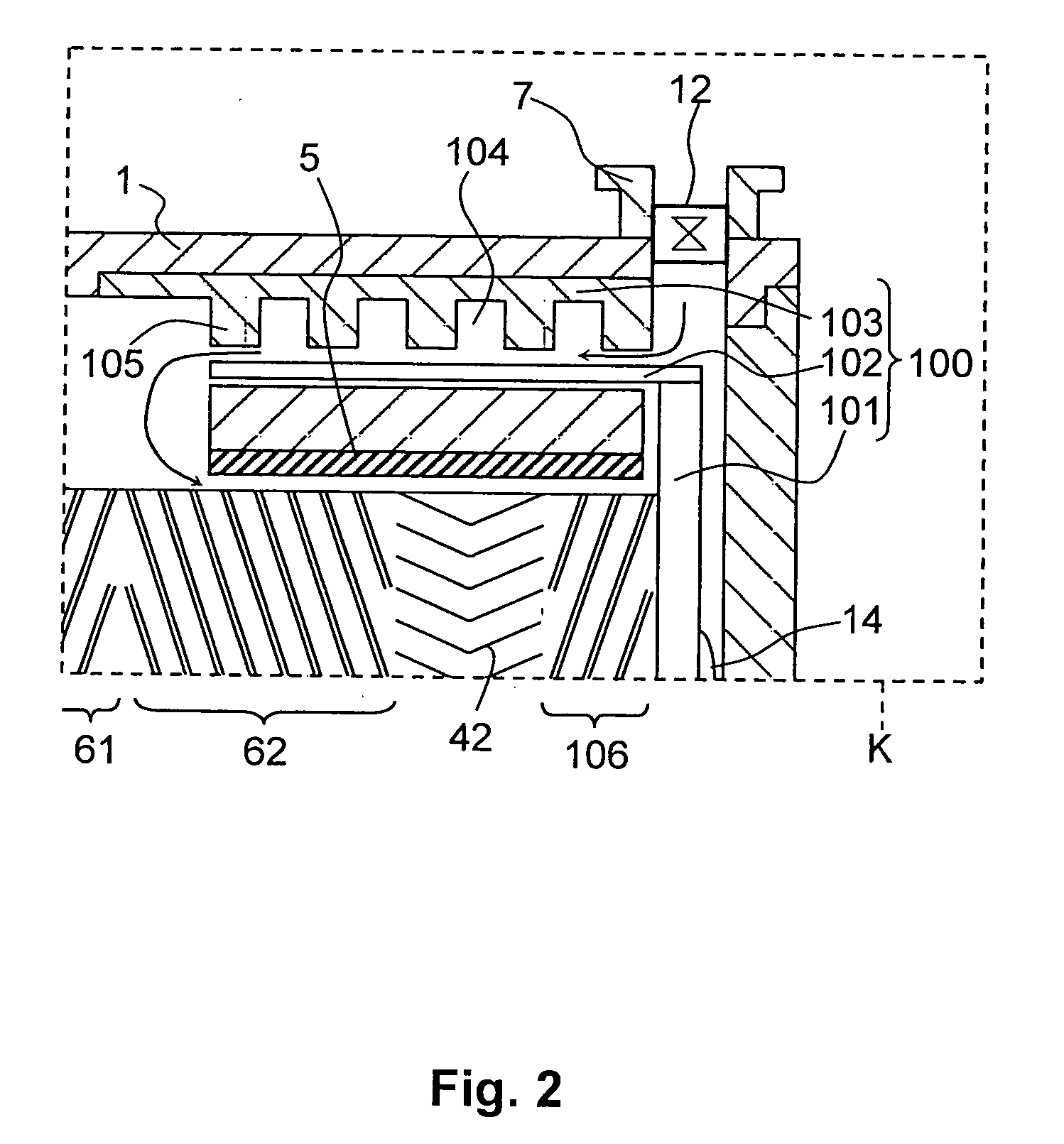

[0023]The second gas bearing 40 includes a gas inlet 41, a shaft-side bearing structure 42 and a bearing gas outlet 44. The bearing structure 42 forms a bearing section 43 extending in the shaft axial direction.

[0024]The bearing structures 32 and 42 include recesses formed in the surface of the shaft 2.

[0025]In the embodiment shown in FIG. 1, each of the gas bearing outlets 34 and 44 is provided with two openings located, respectively, at opposite ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com