Stacking and carrying machine

A handling machine and palletizing technology, which is applied in the field of industrial automation production, can solve the problems of single function realization method and cumbersome structure of the palletizing machine, and achieve the effects of low energy consumption rate, fast rotation speed and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

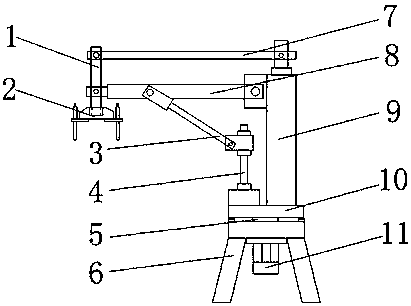

[0023] A palletizing and handling machine, comprising a base 6 and a column 9, a motor 11 is arranged under the base 6, the motor 11 is connected to the rotating base 10 through a rotating shaft 5, the rotating base 10 is provided with a column 9, and the column 9 passes through The hinge is connected with the mechanical arm 8, and the left side of the column 9 is provided with a hydraulic device 4, and the hydraulic device 4 is connected with the connecting rod 3. The connecting rod 3 is connected to the mechanical arm 8, and the end of the mechanical arm 8 is provided with a mechanical claw 2, and the mechanical claw 2 is connected to the column 9 through the connecting rod 1 and the connecting rod 7. An application method of a palletizing and handling machine is as follows: the device is arranged next to the conveyor belt. When carrying goods, the hydraulic device 4 shrinks and drives the mechanical arm 8 to descend through the connecting rod 3. The mechanical claw 2 grabs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com