Cleaning food suction all-in-one machine

An all-in-one, clean technology, applied in the field of agricultural machinery, to achieve the effect of improving work efficiency, saving time, and exquisite structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

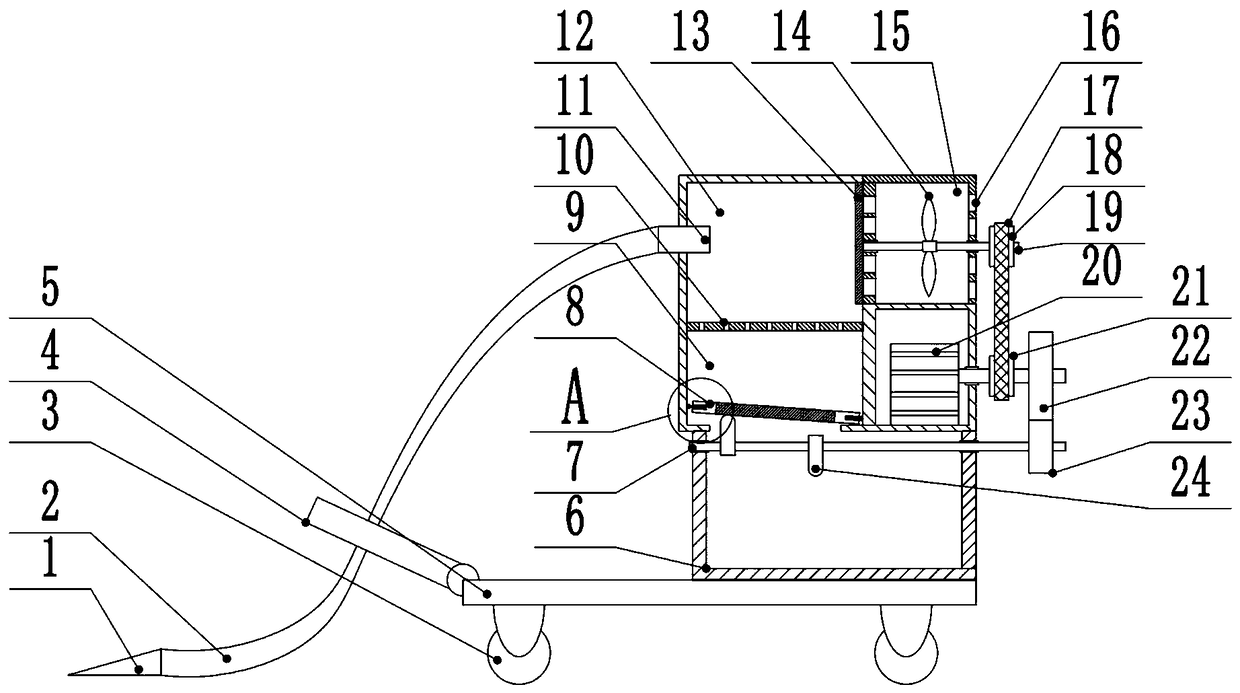

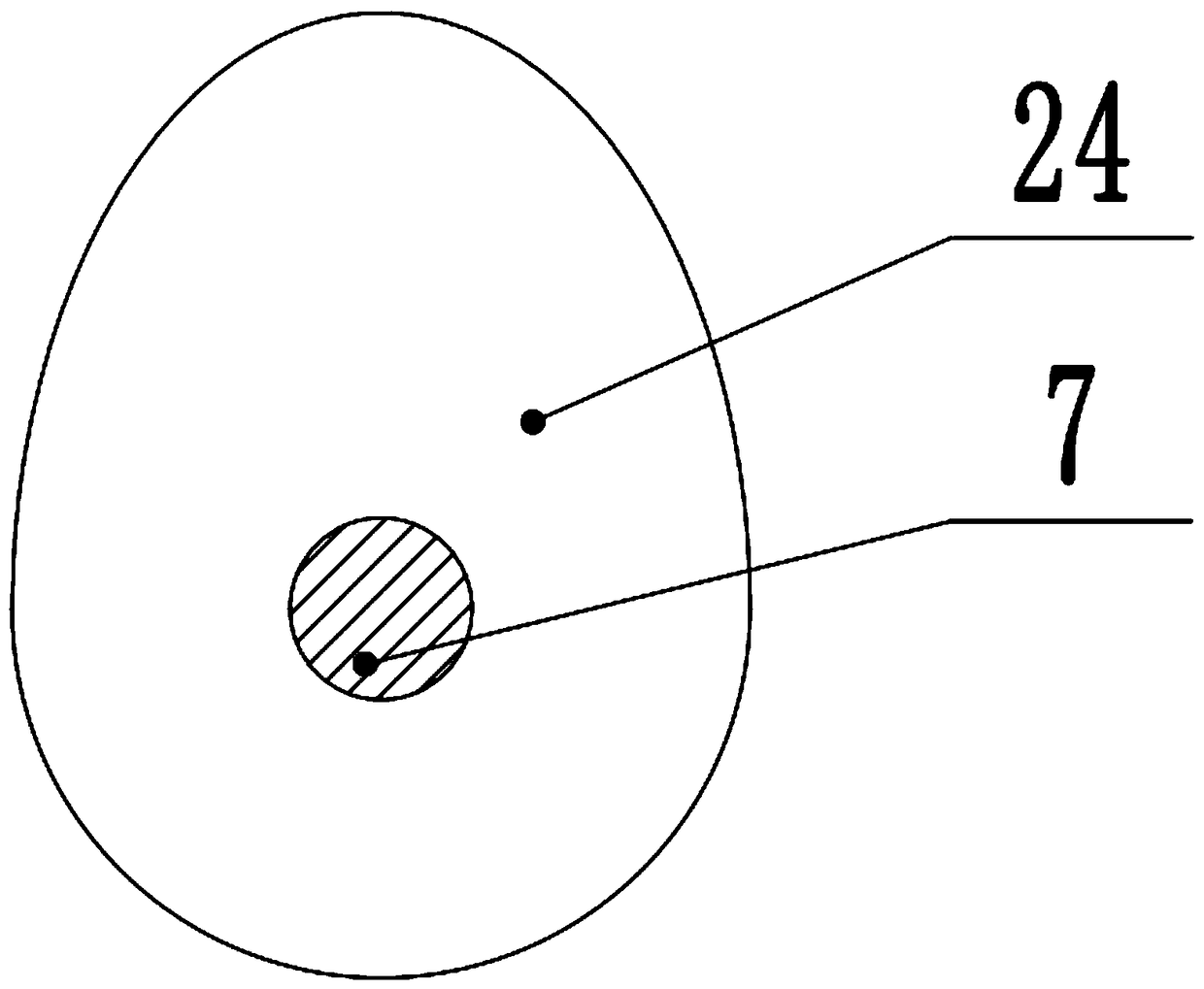

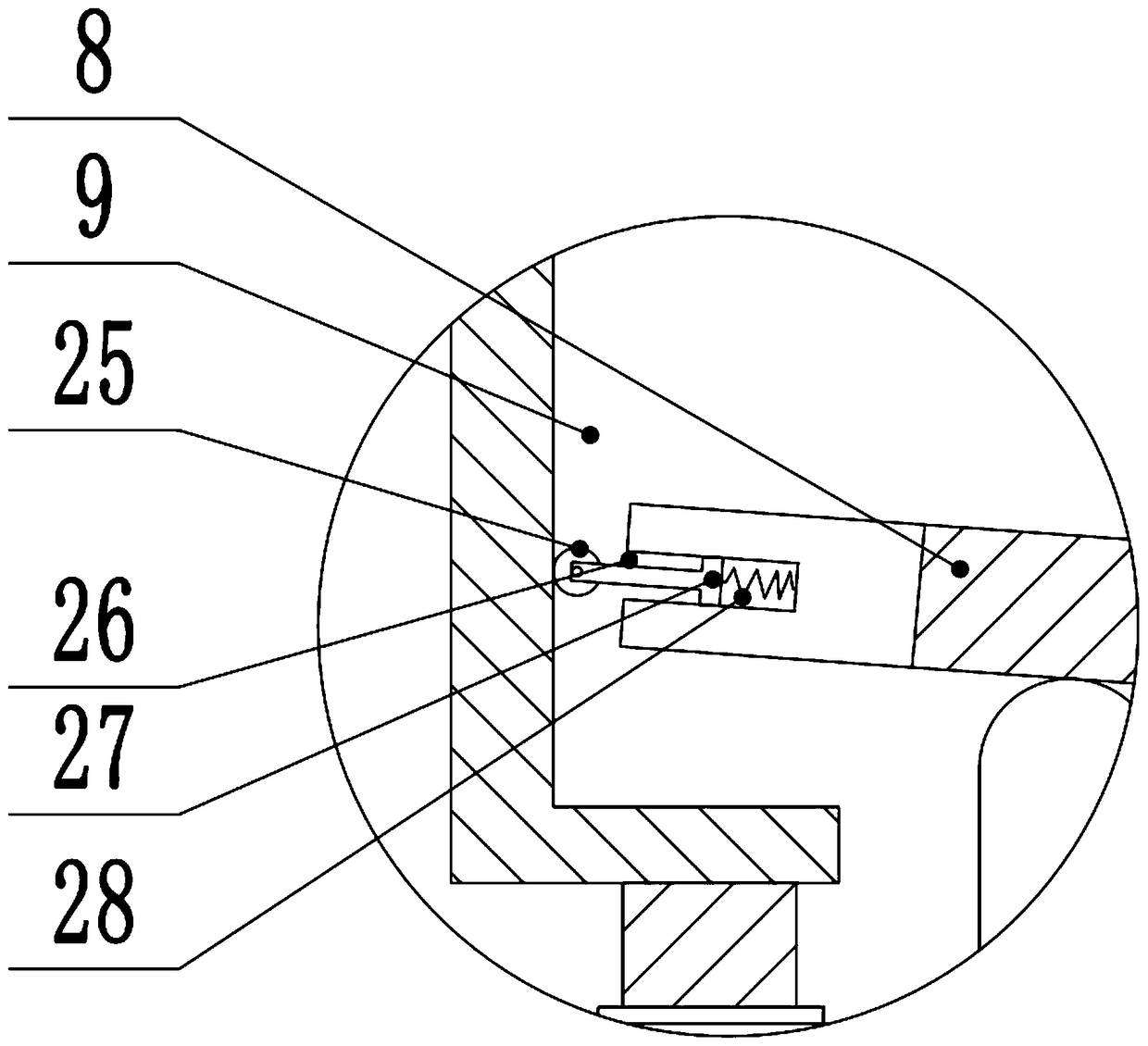

[0025] see figure 1 with 2 , an all-in-one machine for cleaning and absorbing food, comprising a base plate 5, the base plate 5 is fixedly connected to a frame 6, the bottom of the base plate 5 is fixedly connected to a caster 3, and the entire device can be pushed to move freely through the caster wheel 3; the left side of the base plate 5 is hinged with a hose fixing part 4 , the hose fixing part 4 is fixedly connected to the hose 2, the left end of the hose 2 is fixedly connected to the suction head 1, and the food on the ground is sucked into the device through the hose 2 and the suction head 1, and the hose fixing part 4 can control the connection between the suction head 1 and the suction head 1. The angle of the ground; the upper left side of the frame 6 is provided with a separation chamber 12, the left side wall of the separation chamber 12 is provided with a feed port 11, the feed port 11 is fixedly connected to the hose 2, and the right side of the separation chambe...

Embodiment 2

[0028] see Figure 4 The second embodiment is improved on the basis of the first embodiment, the right side of the frame 6 is fixedly connected to the fixed block 29, the fixed block 29 is fixedly connected to the second spring 30, and the other end of the second spring 30 is fixedly connected to the baffle 31, the The baffle plate 31 is slidably connected to the frame 6, and the bottom right side of the frame 6 is provided with a grain unloading port 32.

[0029] In the present invention, during use, the device is first pushed to the place where the grain is dried, the angle between the suction head 1 and the ground is adjusted by rotating the hose fixing part 4, and the motor 20 is started, and the motor 20 drives the fan 14 to rotate through a belt drive, and the fan 14 rotates. 14 forms an airflow from left to right, so that the pressure in the separation chamber 12 decreases, the grain enters the separation chamber 12 through the suction head 1 and the hose 2, and some du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com