Fan blade machining equipment and method

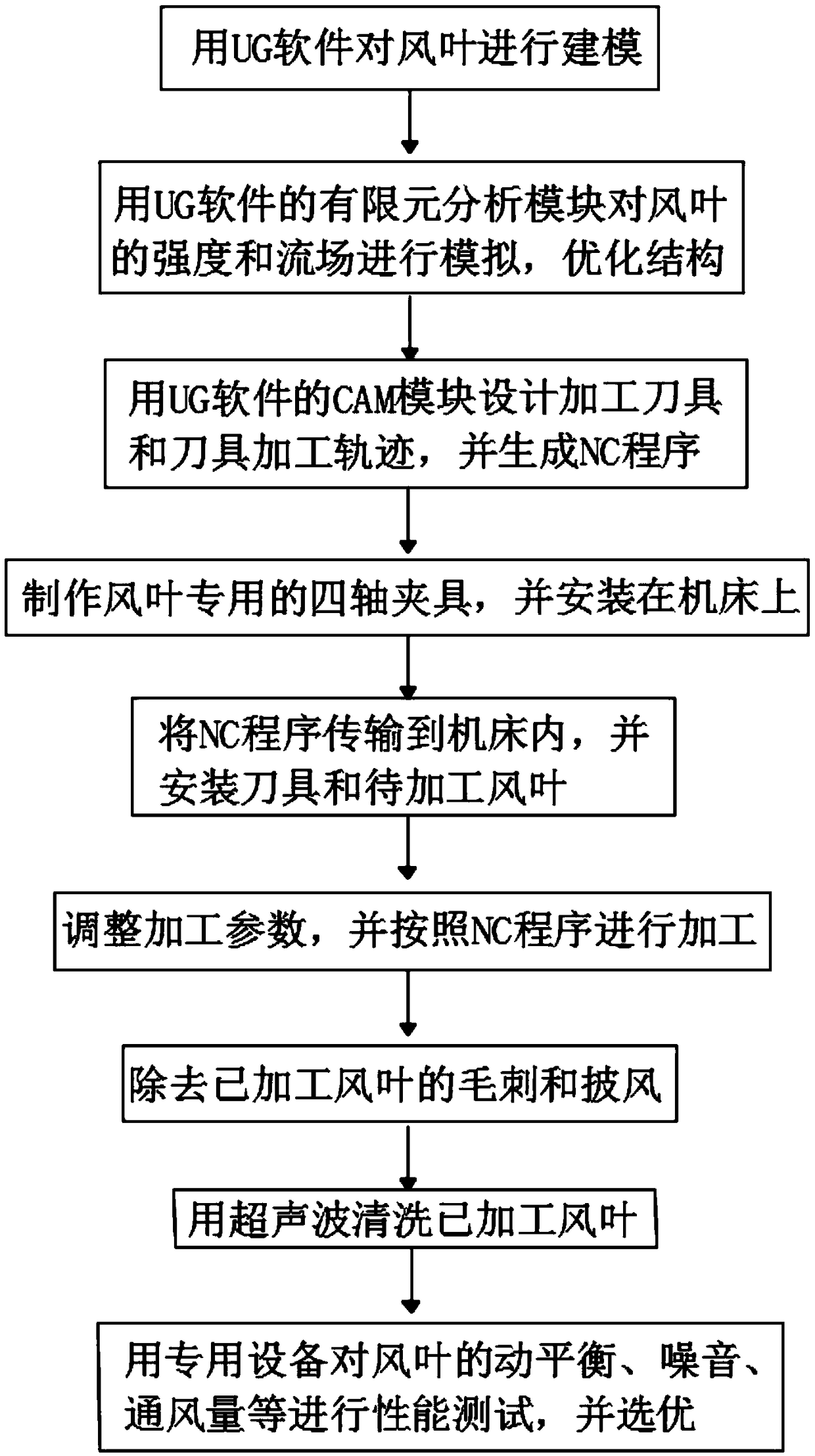

A technology of processing equipment and processing methods, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low processing efficiency, high cost, complicated tool path, etc., and achieve high processing efficiency, improved efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention, but this does not constitute a limitation to the protection scope of the present invention.

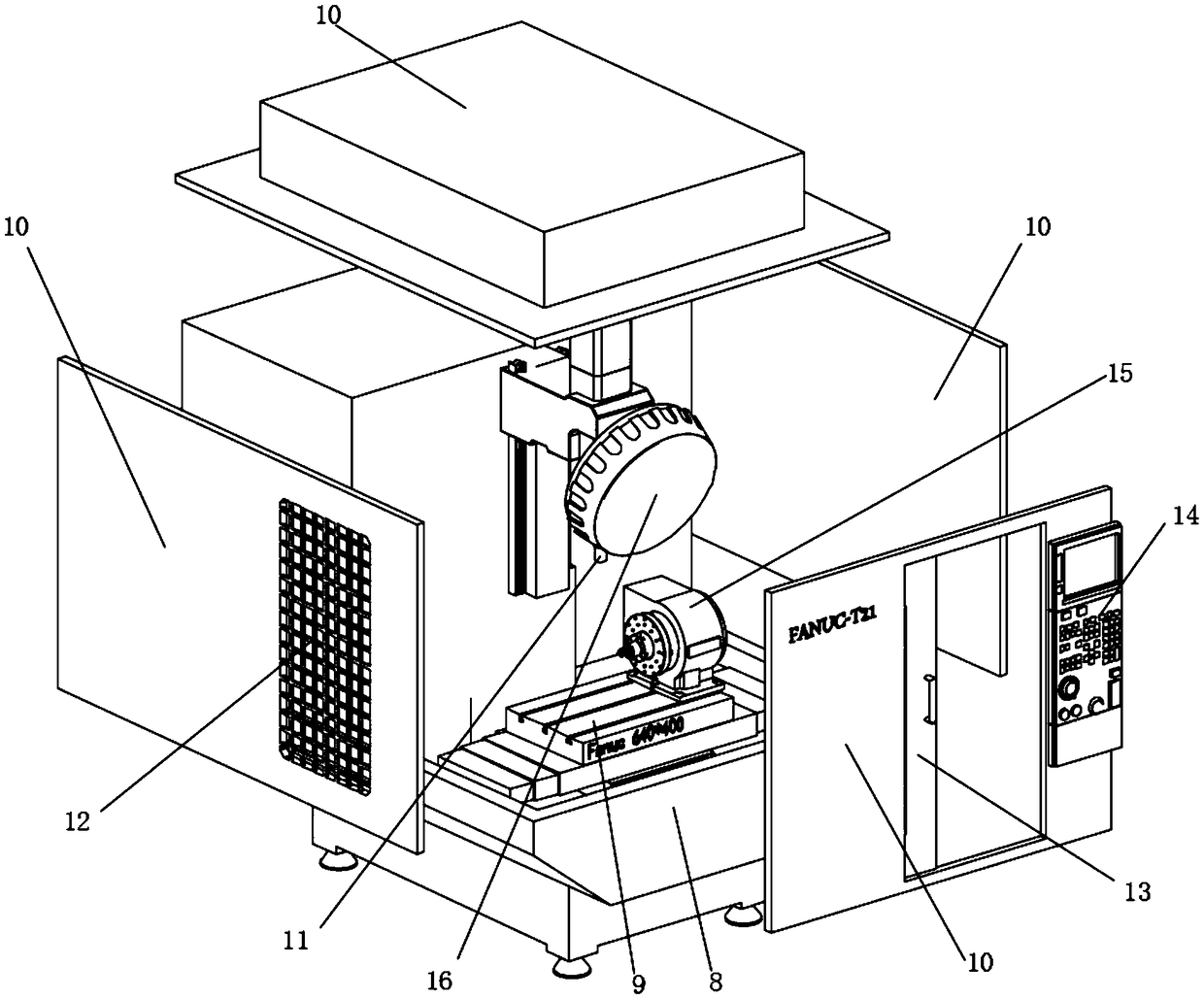

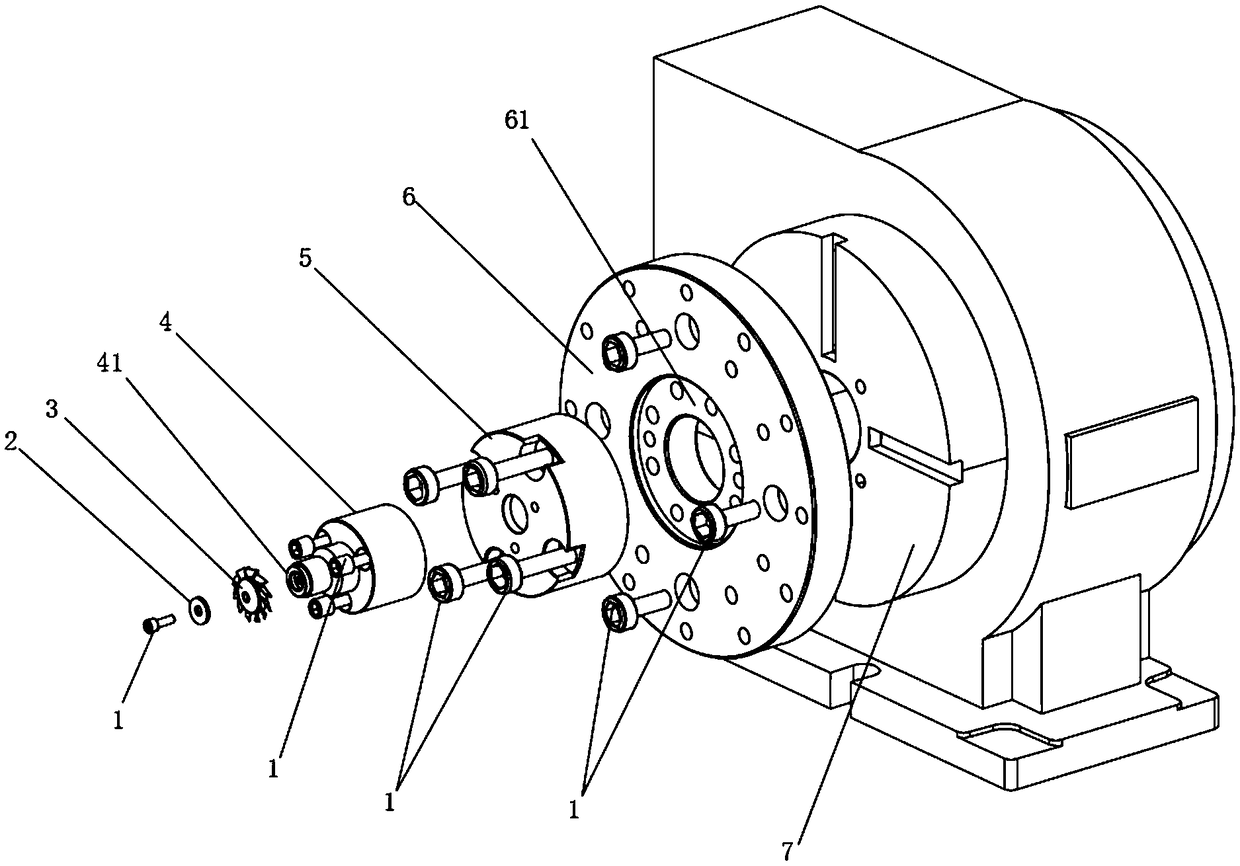

[0026] see figure 1 , figure 2 , are various related diagrams of a wind blade processing equipment provided by the present invention. In this embodiment, a wind blade processing equipment mainly includes: a machine tool 8, a workbench 9 arranged on the machine tool 8, and a The tool magazine 16 on the machine tool 8 is provided with various cutters for processing wind blades in the tool magazine 16, such as flat-bottomed end mills, spherical milling cutters and round nose cutters, etc., and the machining spindle 11 arranged on the machine tool 8, The protective plate 10 arranged around and above the machine tool 8, the protective plate 10 is used to prevent the cut meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com