Curing method of precast concrete integrated pipe gallery

An integrated pipe gallery and concrete technology, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of large maintenance water consumption, high construction cost, and cracks in the side walls of the culvert, achieving environmental friendliness, saving construction time, and improving model Effect of Turnover Speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the technology of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

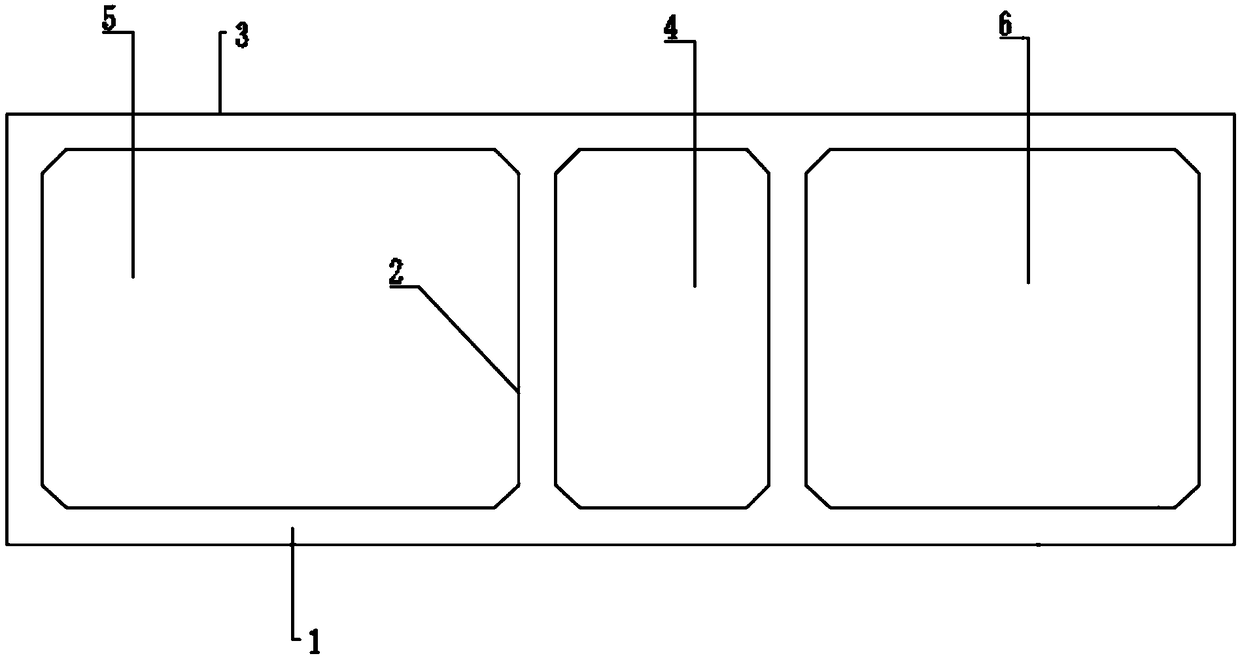

[0014] Such as figure 1 Shown is a schematic diagram of the prefabricated part of the comprehensive pipe gallery of the present invention, wherein 1 is the bottom plate, 2 is the web, 3 is the top plate, 4 is the gas tank, 5 is the comprehensive tank, and 6 is the sewage tank.

[0015] The concrete pouring process of the pipe gallery: horizontal pouring is adopted, and its characteristics are that the height of the A1-type pipe gallery is 3.6 meters, the width is 10.3 meters, and the middle is divided into three warehouses, the comprehensive warehouse, the gas warehouse, the sewag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com