Light guide plate protecting film

A technology of protective film and light guide plate, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of warpage of light guide plate, high thermal expansion rate of PMMA material, poor ductility of PE protective film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

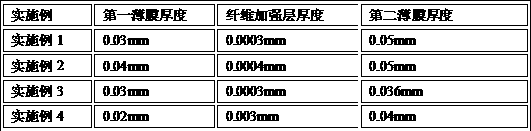

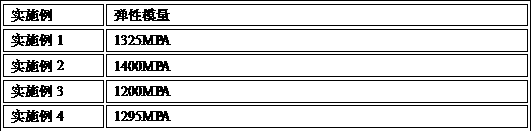

Embodiment 1

[0015] A protective film for a light guide plate comprises a first film, a fiber reinforced layer and a second film from top to bottom, wherein the second film is in contact with the light guide plate.

[0016] The first film is made of polyethylene, the second film is made of a blend of polyethylene and polypropylene, where the ratio of polyethylene to polypropylene is 2:1, and the density of polyethylene in the first and second films is 0.95 , the elastic modulus of the second film is 1100MPA.

[0017] The fiber reinforced layer is formed by blending sodium dodecyl sulfate and carbon nanotubes and coating between the first film and the second film.

Embodiment 2

[0019] A protective film for a light guide plate comprises a first film, a fiber reinforced layer and a second film from top to bottom, wherein the second film is in contact with the light guide plate.

[0020] The first film is made of polyethylene, the second film is made of a blend of polyethylene and polypropylene, where the ratio of polyethylene to polypropylene is 2.5:1, and the density of polyethylene in the first and second films is 0.942 , the elastic modulus of the second film is 1000MPA.

[0021] The fiber reinforced layer is formed by blending sodium dodecyl sulfate and carbon nanotubes and coating between the first film and the second film.

Embodiment 3

[0023] A protective film for a light guide plate comprises a first film, a fiber reinforced layer and a second film from top to bottom, wherein the second film is in contact with the light guide plate.

[0024] The first film is made of polyethylene, the second film is made of a blend of polyethylene and polypropylene, where the ratio of polyethylene to polypropylene is 3:1, and the density of polyethylene in the first film and the second film is 0.96 , the elastic modulus of the second film is 1000MPA.

[0025] The fiber reinforced layer is formed by blending sodium dodecyl sulfate and carbon nanotubes and coating between the first film and the second film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com