Composite sandglass spring structure

An hourglass spring and composite technology, applied in the direction of the spring, the device for lateral relative movement between the chassis and the bogie, can solve the problems that affect the economic development of the enterprise, require high floor space, and increase the cost of accumulation, and achieve good results. Economic use value, excellent vibration reduction, high load-bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

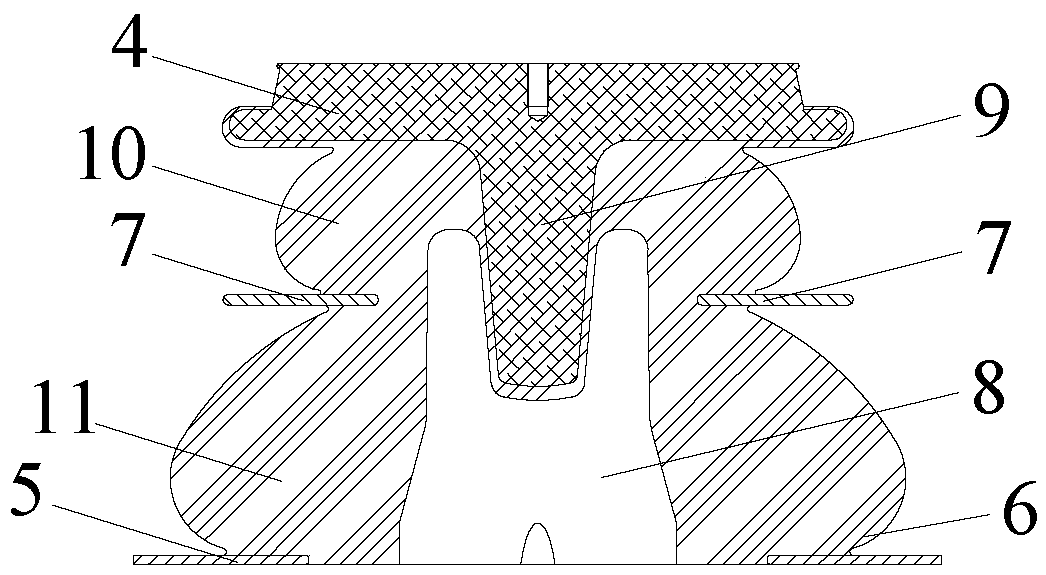

[0018] Such as figure 2 , Figure 4 As shown, the present invention comprises connecting plate, is divided into upper connecting plate 4, lower connecting plate 5, is vulcanized with rubber 6 between upper connecting plate 4, lower connecting plate 5, and rubber 6 is that the diameter of upper and lower ends is big, and middle diameter is little. One-piece hourglass-shaped structure, metal sheet 7 is inserted at the intersection of the upper part 10 and the lower part 11 of the rubber 6, which can achieve higher load capacity, fast rebound, excellent vibration damping, small creep, and impact resistance in a limited area , low natural frequency, etc., so that it can meet the use of more working conditions and occasions, and has a compact structure, low manufacturing cost, and can ensure the performance and life of the hourglass spring, and has good economic use value.

[0019] The middle part of the upper connecting plate 4 is provided with a protrusion 9 extending to the lo...

Embodiment 2

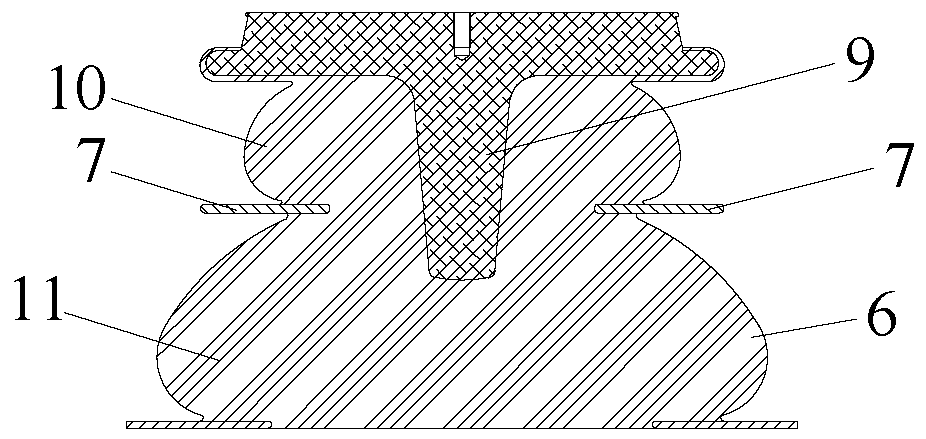

[0023] Such as image 3 , Figure 4 As shown, the rubber 6 is a solid structure, which also has a good damping effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com