Proton exchange membrane for battery, preparation method and nanofiber composite structure

A technology of proton exchange membranes and nanofibers, which is applied in nanotechnology, fuel cells, nanotechnology, etc. for materials and surface science, and can solve the problems of thermal stability, chemical stability and low structural stability of proton exchange membranes. Poor membrane proton conductivity, complex proton exchange membrane preparation process and other problems, to achieve the effect of enhanced proton transport capability, good dimensional stability, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

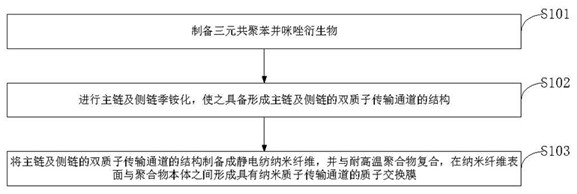

[0088] like figure 1 As shown, the preparation method of the stable and high-efficiency proton exchange membrane provided by the embodiment of the present invention includes:

[0089] S101, preparing a ternary copolymerized benzimidazole derivative.

[0090] S102, the main chain and the side chain are quaternized so as to have the structure of forming a double proton transport channel of the main chain and the side chain.

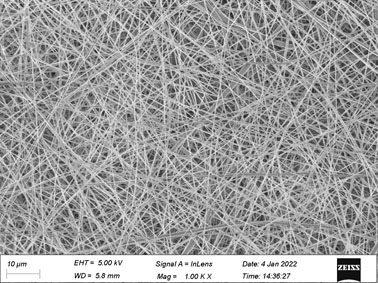

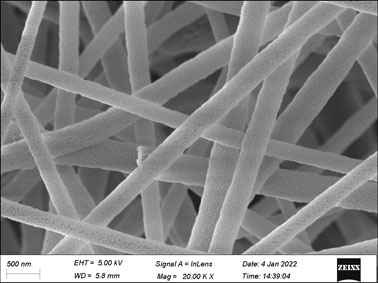

[0091] S103, the structure of the double proton transport channel of the main chain and the side chain is prepared into an electrospun nanofiber, which is compounded with a high temperature resistant polymer to form a proton exchange membrane with a nanoproton transport channel between the surface of the nanofiber and the polymer body .

[0092] In a preferred embodiment of the present invention, the ternary copolymerized benzimidazole derivative of the step S101 is made of biphenylenediamine monomer, aromatic diacid monomer, amino or hydroxyl substitute...

Embodiment 1

[0118] Preparation of terpolymerized benzimidazole derivatives. 3,3'-diaminobenzidine was first recrystallized from 4M hydrochloric acid to give the monomer as a white hydrochloride salt. Take 1.8006 grams of diaminobenzidine hydrochloride and 0.8306 grams of isophthalic acid / 5-aminoisophthalic acid and dissolve them in 25 grams of PDMA (methanesulfonic acid / P 2 O 5 = 10:1). Under mechanical stirring, the system was heated to 180 degrees Celsius and reacted for 5 hours. The reaction mixture was poured into 1000 mL of 2M aqueous sodium hydroxide solution, resulting in a fibrous precipitate. The precipitate was filtered, washed, and dried in an oven at 120 degrees Celsius.

Embodiment 2

[0120] Quaternization of the backbone of polybenzimidazole derivatives. 15 grams of polybenzimidazole derivatives and 400 grams of DMSO were placed in a three-necked flask, and were dissolved by mechanical stirring at 60 degrees Celsius for 12 hours. 8.1 g of KOH powder was added and stirring was continued at 70 degrees Celsius for 17 hours. Then 18 ml of methyl iodide were added and the reaction was continued at 70 degrees Celsius for 20 hours. Precipitated with 10 volumes of acetone, the resulting polymer was oven dried at 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com