Novel mounting bracket of pilot and brake travel switch

A technology for switching mounting brackets and braking strokes, which is applied in the directions of bogies, transportation and packaging, railway car body components, etc., can solve the problems of low first-order modal frequency of brackets, reduced operating safety of rail vehicles, and low rigidity, etc. Achieve the effect of light weight, high reliability and improved overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

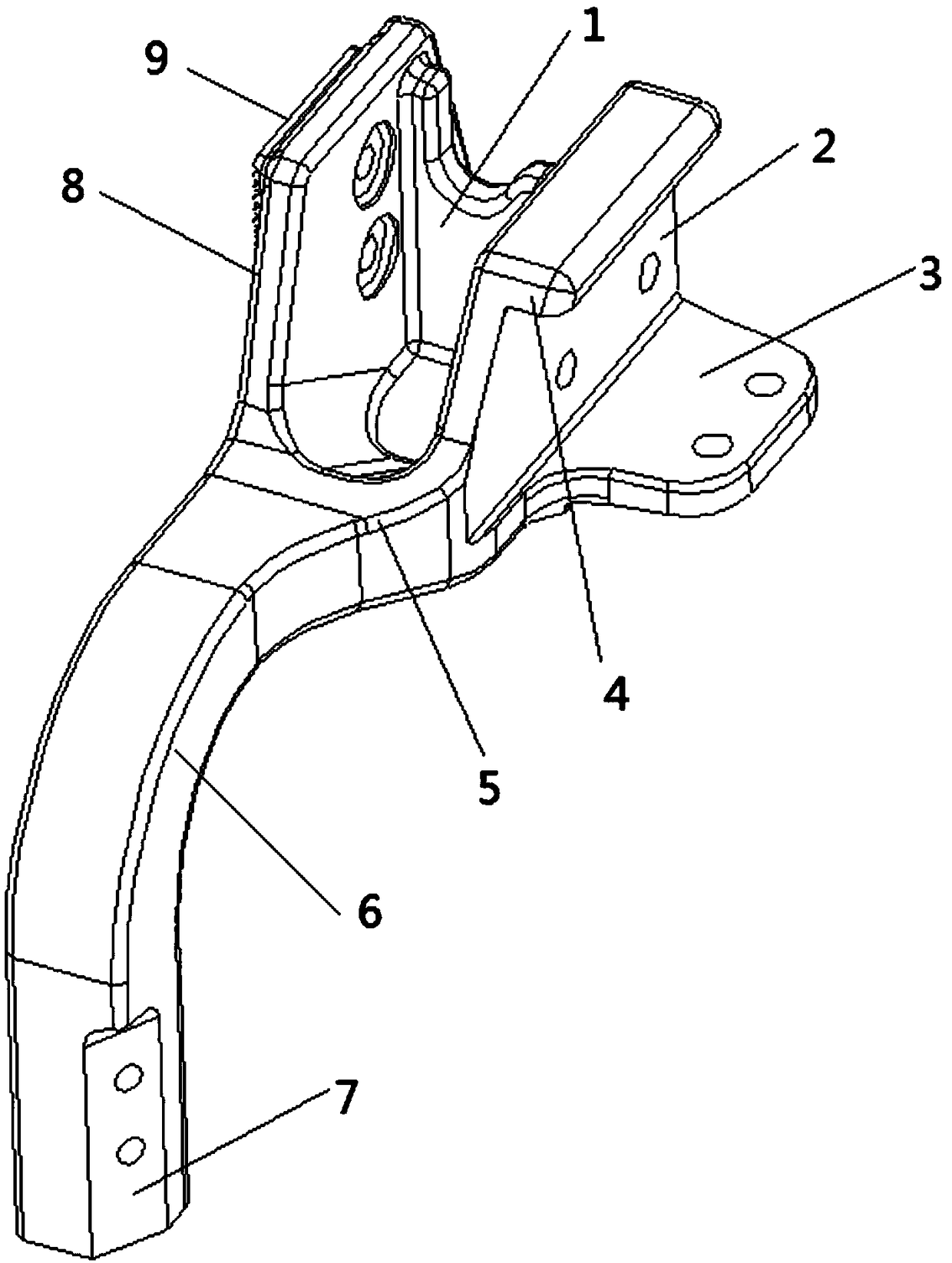

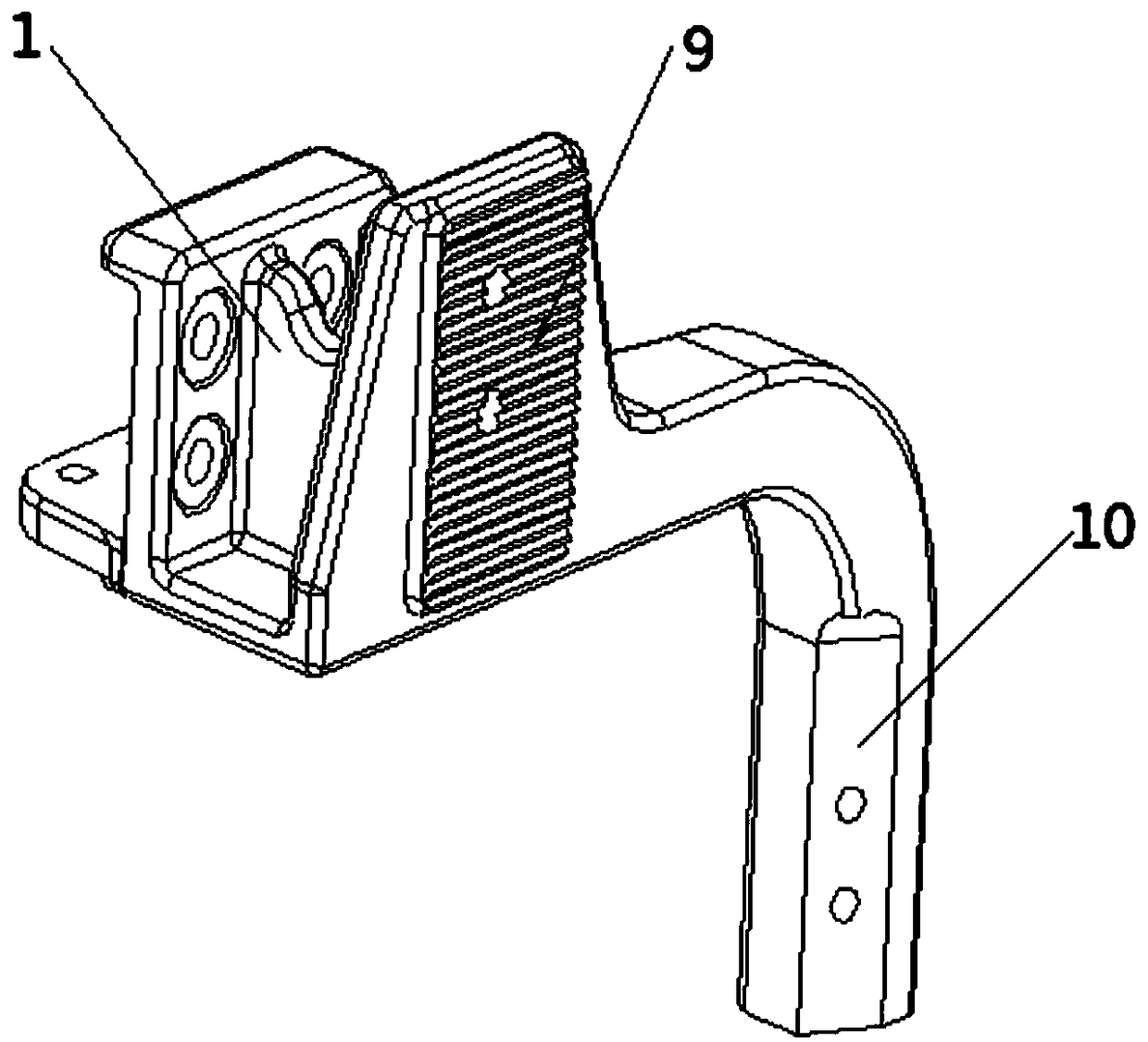

[0016] refer to figure 1 , figure 2 , the specific embodiment of the present invention includes the mounting end and the cantilever 6, one side 2 of the mounting end is the connecting surface of the axle box end, and the opposite side 8 is the mounting surface of the travel switch, and the above mounting surface of the travel switch is a toothed connecting surface 9, Since the weight of the brake travel switch is close to 10KG, under the condition of line vibration, it will have a greater impact on the bolt connection. Since there are only two bolts installed at the end of the axle box, in order to ensure sufficient connection reliability, the tooth surface and the tooth surface are used to ensure sufficient connection reliability. The friction between the surfaces ensures a firm and stable installation. The lower part of the cantilever is processed with a longitudinally inward 30-degree slope 10 relative to the tooth-shaped connecting surface 9 as the installation surface f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com