Sound-insulation plate for hull

A sound insulation board and hull technology, applied in the direction of hull paneling, hull, hull parts, etc., can solve the problems of unsatisfactory sound insulation and noise reduction, no sound wave noise reduction structure, sound wave degradation and disappearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

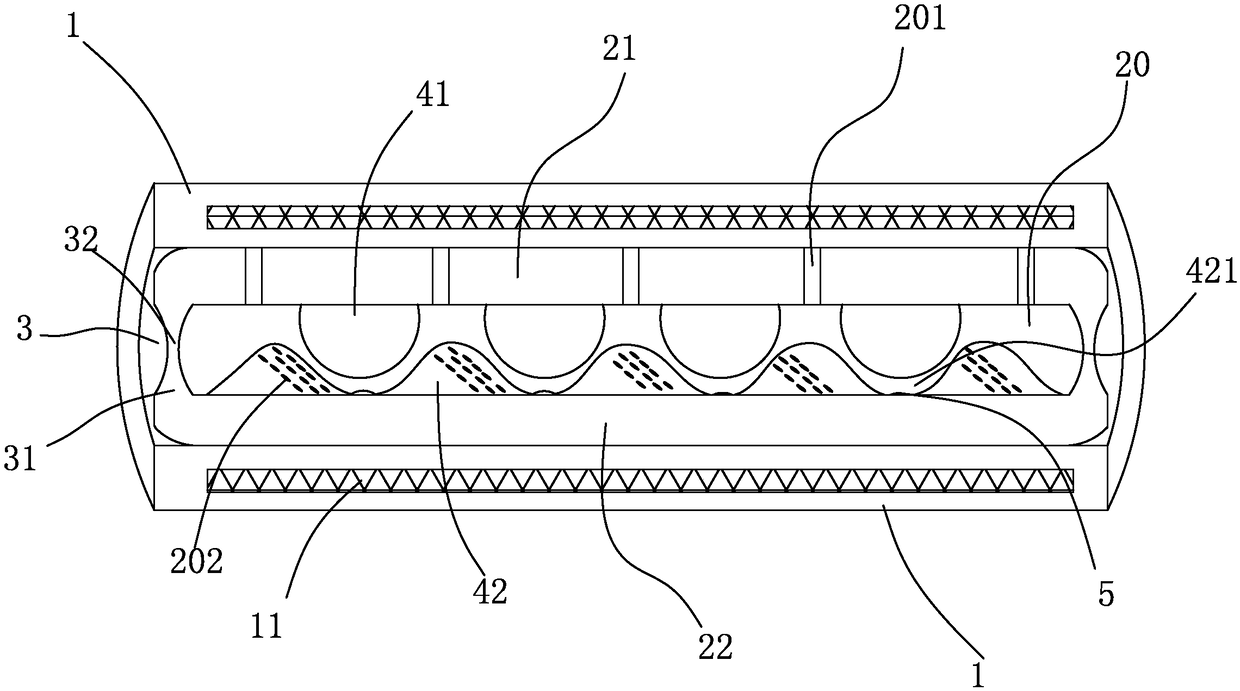

[0015] refer to Figure 1 to Figure 2 Embodiments of the present invention will be further described.

[0016] The specific structure of this embodiment: the sound insulation board includes two outer plates 1 and a sound-absorbing assembly placed between the two outer plates 1 , and the outer plates 1 are filled with sound-absorbing cotton 11 .

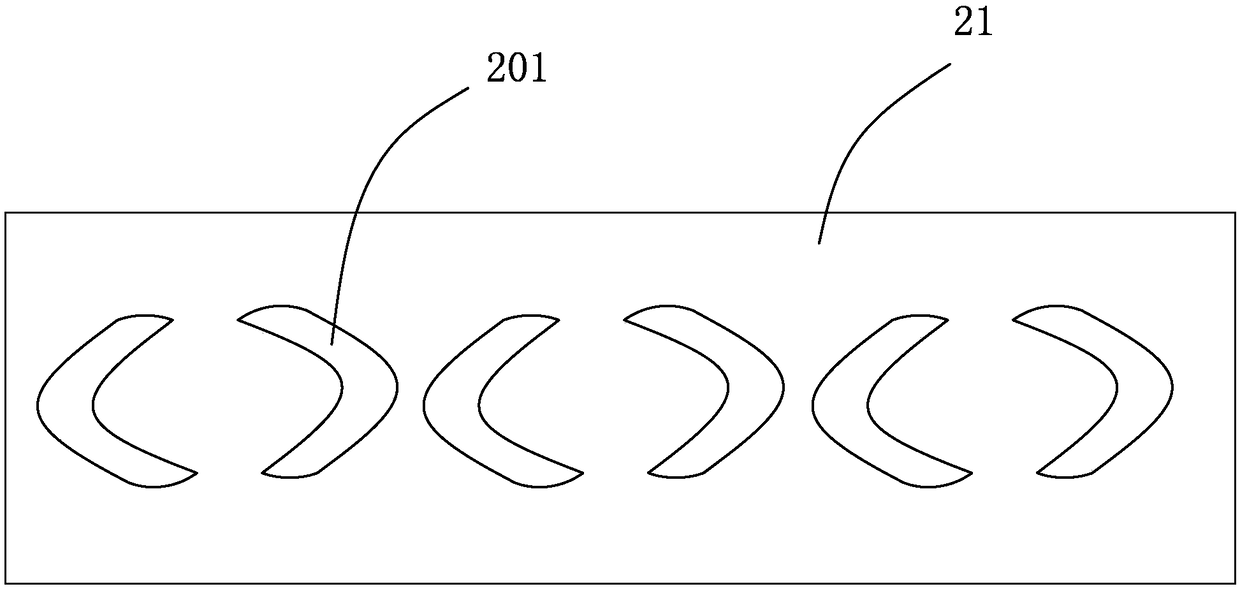

[0017] The sound-absorbing assembly is formed by sealing the periphery of the first sound-absorbing plate 21 and the second sound-absorbing plate 22 through the edge sealing strip 3, and constitutes the sound-absorbing chamber 20, in order to realize the extrusion of the first sound-absorbing plate 21 to the second sound-absorbing plate 22 Vibration, so the edge seal 3 must have elasticity. The thickness of the first sound-absorbing plate 21 and the second sound-absorbing plate 22 need to be equal, and the structure stability and the sound-absorbing ability of the sound-absorbing assembly composed of the combination of the two are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com