Propylene epoxide-carbon dioxide copolymer and preparation method thereof

A technology of carbon dioxide and propylene oxide, which is applied in the field of polymers, can solve the problems of complex reaction process and difficult control of the synthesis process, and achieve the effects of easy selection, reduced production cost and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

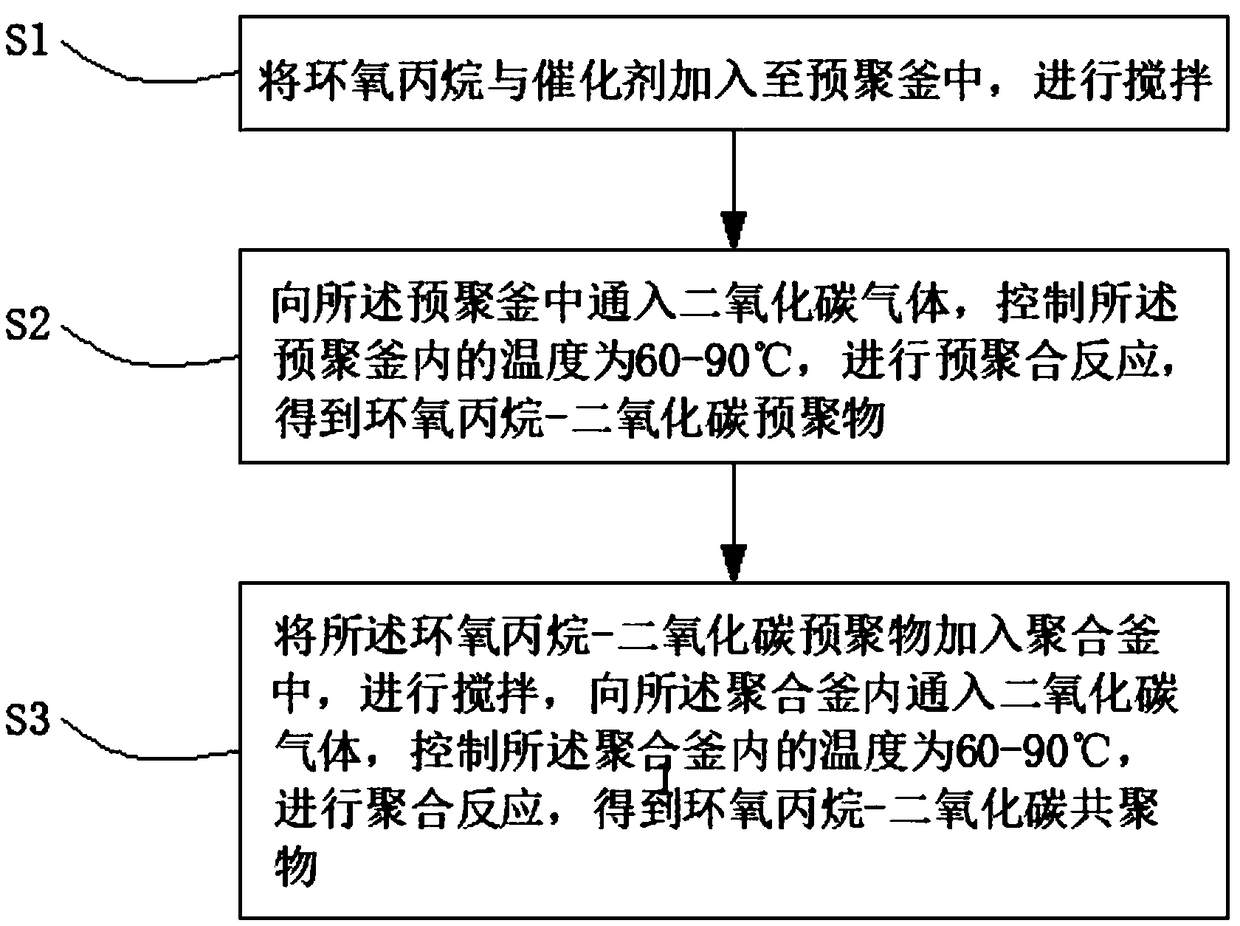

[0026] The invention provides a kind of preparation method of propylene oxide-carbon dioxide copolymer, see figure 1 As shown, the preparation method divides the preparation of propylene oxide-carbon dioxide copolymer into two processes of pre-polymerization and polymerization, wherein the pre-polymerization is carried out in a pre-polymerization kettle, and the polymerization is carried out in a polymerization kettle, that is, the present invention The preparation method of the provided propylene oxide-carbon dioxide copolymer adopts a multi-reservoir series polymerization process.

[0027] The specific preparation process is as follows: first, propylene oxide and the catalyst are added into the prepolymerization tank according to a certain ratio, and then stirred, and then carbon dioxide gas is introduced into the prepolymerization tank, and the amount of carbon dioxide added is determined according to the amount of propylene oxide added. ;Control the pressure in the prepoly...

Embodiment 1

[0036] The present embodiment provides a kind of preparation method of propylene oxide-carbon dioxide copolymer, and this preparation method comprises the steps:

[0037] S1: Add propylene oxide whose volume is 1 / 4 of the volume of the pre-polymerization tank and a catalyst whose mass is 0.5% of the mass of propylene oxide to the pre-polymerization tank, and stir at a stirring speed of 10 rpm;

[0038] S2: From the bottom of the prepolymerization kettle, feed carbon dioxide gas whose quality is 40% of the propylene oxide feed quality into the prepolymerization kettle, control the pressure in the prepolymerization kettle to be 4.0Mpag, and control the temperature in the prepolymerization kettle to be 60 ℃, carry out the prepolymerization reaction until the viscosity of the product in the prepolymerization tank is 200cP, and obtain the propylene oxide-carbon dioxide prepolymer;

[0039] S3: Add the propylene oxide-carbon dioxide prepolymer into the polymerization kettle, stir at...

Embodiment 2

[0044] Different from Example 1, the preparation method of the propylene oxide-carbon dioxide copolymer provided in this example comprises the following steps:

[0045] S1: Add propylene oxide whose volume is 1 / 2 of the volume of the pre-polymerization tank and catalyst whose mass is 1.5% of the mass of propylene oxide to the pre-polymerization tank, and stir at a stirring speed of 40 rpm;

[0046] S2: From the bottom of the prepolymerization kettle, feed carbon dioxide gas with a quality of 60% of the propylene oxide feed quality into the prepolymerization kettle, control the pressure in the prepolymerization kettle to be 5.5Mpag, and control the temperature in the prepolymerization kettle to be 75 ℃, carry out the prepolymerization reaction until the viscosity of the product in the prepolymerization tank is 450cP, and obtain the propylene oxide-carbon dioxide prepolymer;

[0047] S3: Add the propylene oxide-carbon dioxide prepolymer into the polymerization kettle, stir at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com