Anti-aging polyethylene composite plastic and preparation method thereof

A composite plastic and polyethylene technology, applied in the field of polyethylene processing, can solve the problems of poor heat resistance, poor molding shrinkage, waste of resources, etc., achieve broad market prospects, excellent flame retardancy and mechanical properties, and avoid serious aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

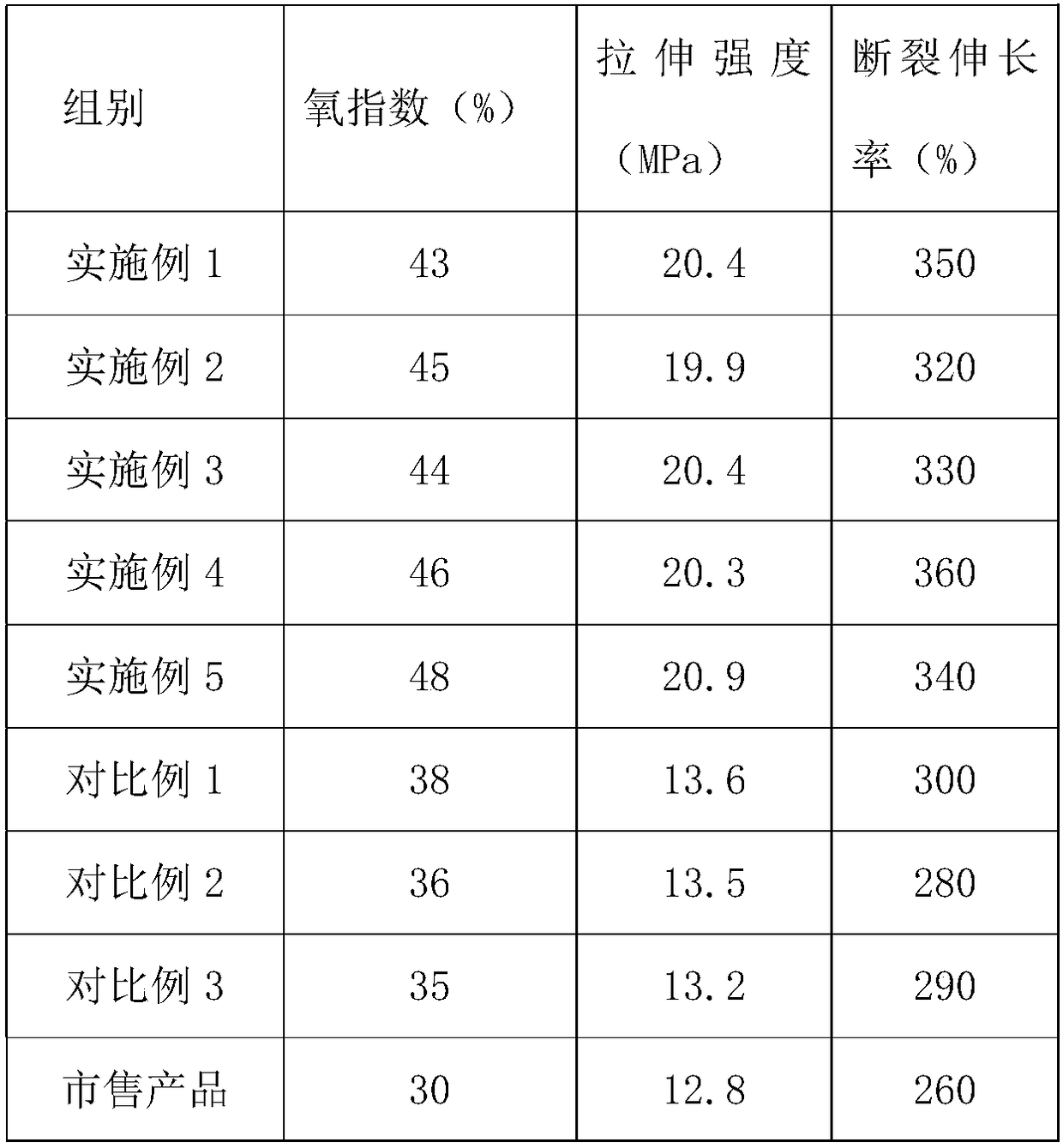

Examples

Embodiment 1

[0021] An anti-aging polyethylene composite plastic, comprising the following raw materials in parts by weight: 120 parts of polyethylene, 50 parts of maleic anhydride grafted polypropylene, 5 parts of polycarbonate, 15 parts of graphite powder, 15 parts of calcium aluminum borosilicate 10 parts, 10 parts of pyrophyllite, 2 parts of trioctyl trimellitate, 10 parts of antistatic agent, 10 parts of light stabilizer, 10 parts of dibasic lead phosphite, and 10 parts of monoammonium phosphate.

[0022] The antistatic agent is an ethoxylated alkyl acid amine.

[0023] Described light stabilizer is one or more mixtures in light stabilizer 99, light stabilizer 3529 and light stabilizer 2020, and the mass ratio of light stabilizer 99, light stabilizer 3529 and light stabilizer 2020 is 1:1.5: 1.8.

[0024] In the present embodiment, the preparation method of the anti-aging polyethylene composite plastic, the steps are as follows:

[0025] 1) Weighing pyrophyllite and trioctyl trimelli...

Embodiment 2

[0032] An anti-aging polyethylene composite plastic, comprising the following raw materials in parts by weight: 150 parts of polyethylene, 90 parts of maleic anhydride grafted polypropylene, 12 parts of polycarbonate, 25 parts of graphite powder, and 30 parts of calcium aluminum borosilicate 20 parts of pyrophyllite, 8 parts of trioctyl trimellitate, 18 parts of antistatic agent, 12 parts of light stabilizer, 20 parts of dibasic lead phosphite, and 15 parts of monoammonium phosphate.

[0033] The antistatic agent is pentamethylenediamine.

[0034] The light stabilizer is light stabilizer 99.

[0035] In the present embodiment, the preparation method of the anti-aging polyethylene composite plastic, the steps are as follows:

[0036] 1) Weighing pyrophyllite and trioctyl trimellitate, pulverizing, after pulverizing, passing through a 70-mesh sieve to obtain mixture A;

[0037] 3) Add acetone solution as a solvent to the first mixture, then stir and mix, let stand for 30min, t...

Embodiment 3

[0043] An anti-aging polyethylene composite plastic, comprising the following raw materials in parts by weight: 130 parts of polyethylene, 60 parts of maleic anhydride grafted polypropylene, 7 parts of polycarbonate, 19 parts of graphite powder, and 16 parts of calcium aluminum borosilicate 12 parts of pyrophyllite, 3 parts of trioctyl trimellitate, 12 parts of antistatic agent, 11 parts of light stabilizer, 12 parts of dibasic lead phosphite, and 11 parts of monoammonium phosphate.

[0044] The antistatic agent is an ethoxylated alkyl acid amine.

[0045] The light stabilizer is a mixture of light stabilizer 3529 and light stabilizer 2020, and the mass ratio of light stabilizer 3529 and light stabilizer 2020 is 1:1.5.

[0046] In the present embodiment, the preparation method of the anti-aging polyethylene composite plastic, the steps are as follows:

[0047] 1) Weighing pyrophyllite and trioctyl trimellitate, pulverizing, after pulverizing, passing through a 50-mesh sieve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com