Mixing improvement method and blending method for phyllite weathered soil and red clay

A technology of red clay and weathered soil, applied in roads, tracks, buildings, etc., can solve the problems of the compaction coefficient failing to meet the standard requirements, increasing costs, and difficult use of roadbed fillers, so as to achieve easy-to-qualify roadbed compaction quality and economical reinforcement Effect of Material Royalty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

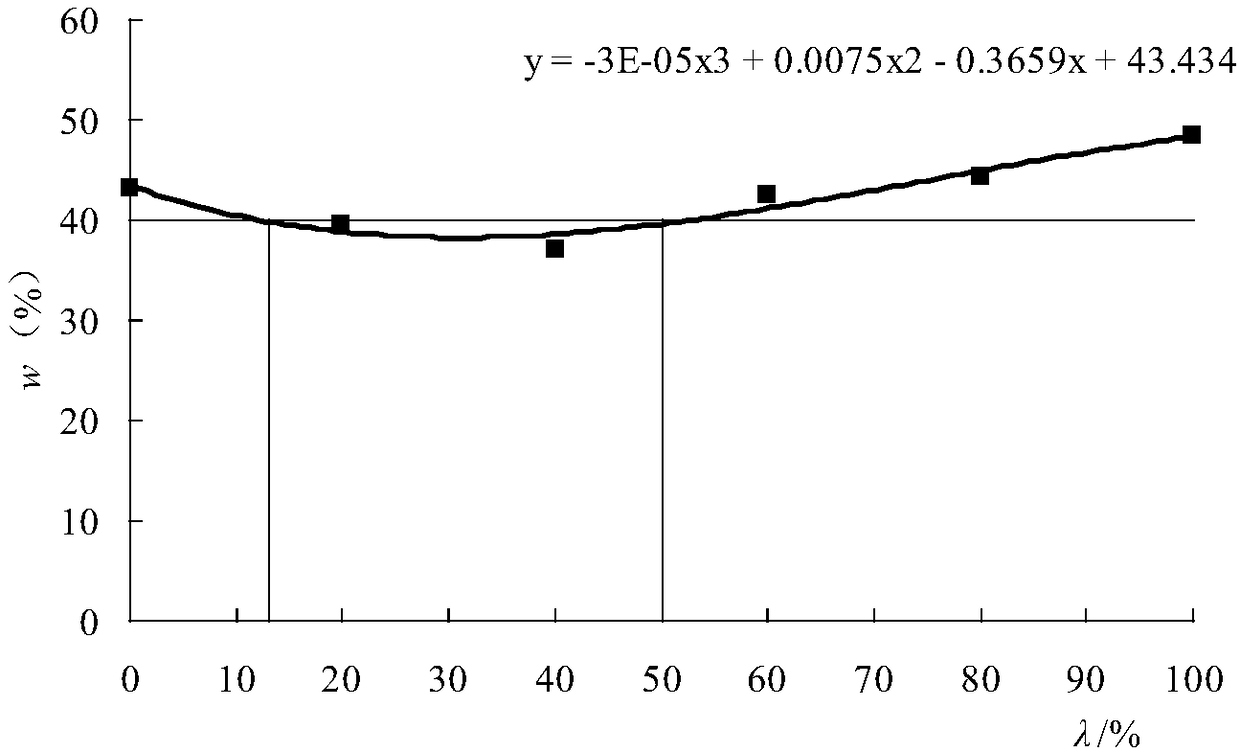

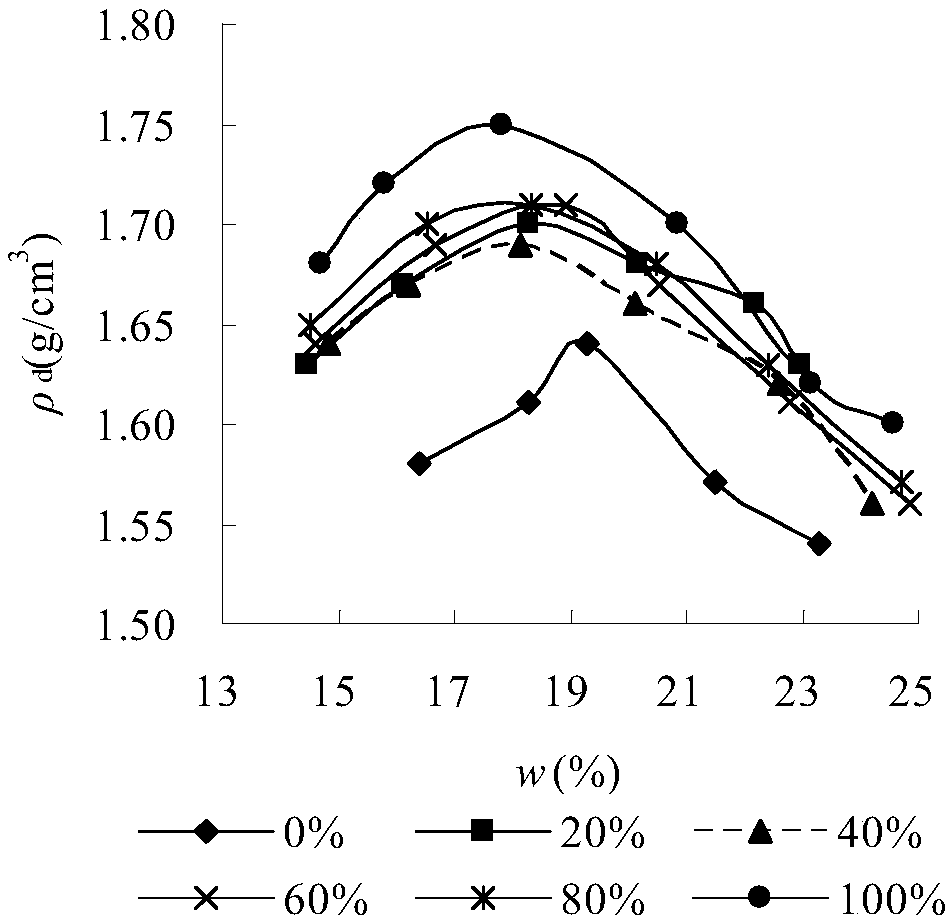

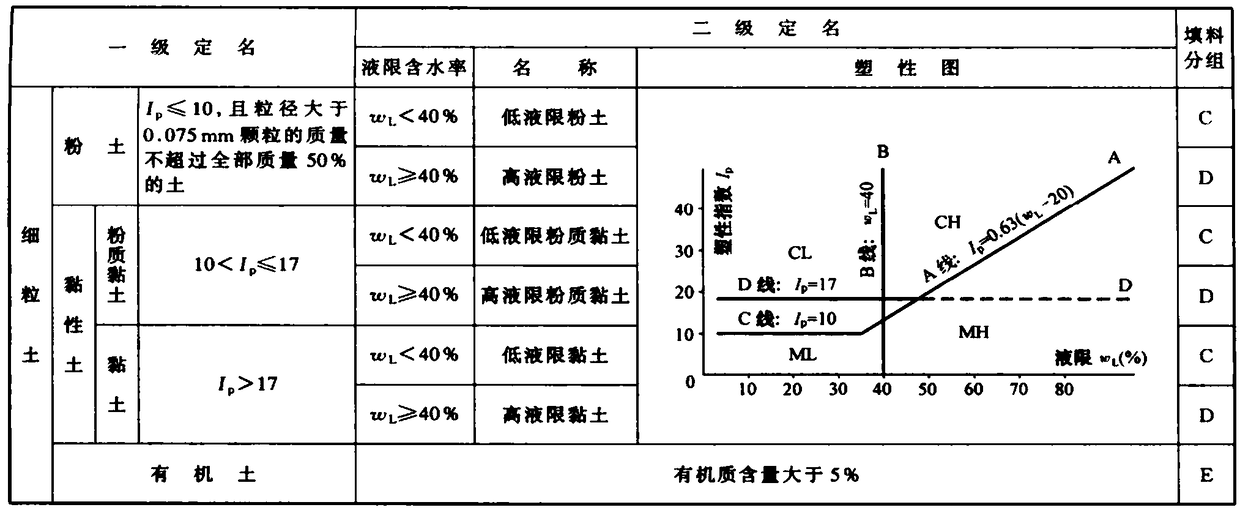

[0049] Please refer to Figure 1-2 , the method of mixing and improving phyllite weathered soil and red clay, the method is to mix a certain proportion of red clay into the phyllite weathered soil to form a mixed filler of Group C filler whose liquid limit is less than 40%. Two kinds of D-group fillers (bad fillers) which are not suitable for use are changed into C-group fillers available for roadbeds, which expands the application range of roadbed fillers. The mixed filler formed by blending phyllite weathered soil and red clay improves the strength and stability of phyllite weathered soil, and at the same time reduces the cracking defects of red clay after drying and wetting cycles. The mixed filler uses the high dispersion of phyllite weathered soil to reduce the high liquid limit and high shrinkage rate of red clay, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com