Temporary structure for installation of continuous steel girder bridge and beam segment construction method thereof

A temporary structure and installation technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficulty in erecting main beams, affecting the lower traffic, high cost, and achieving easy installation and disassembly, cost saving, and easy transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

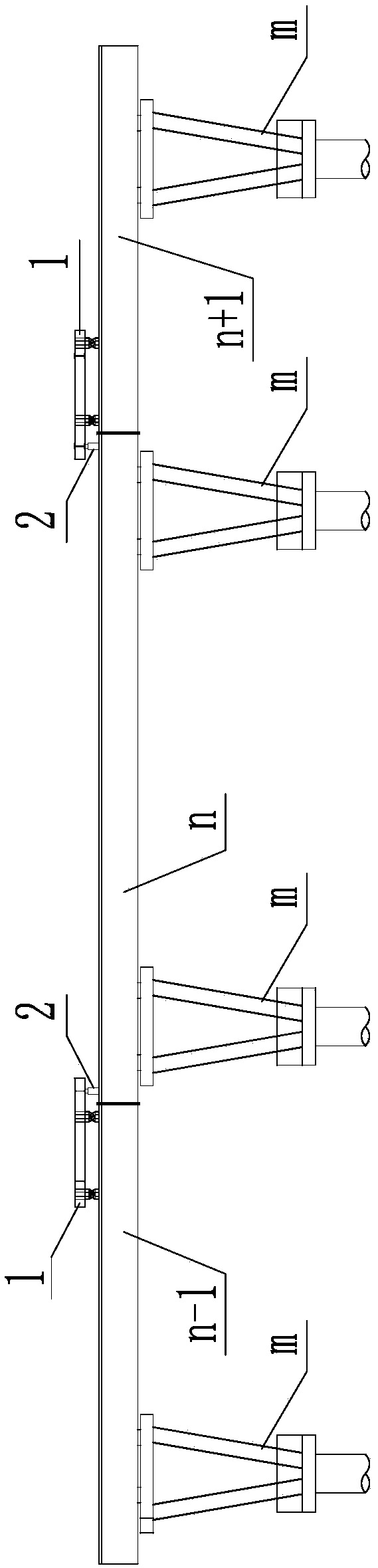

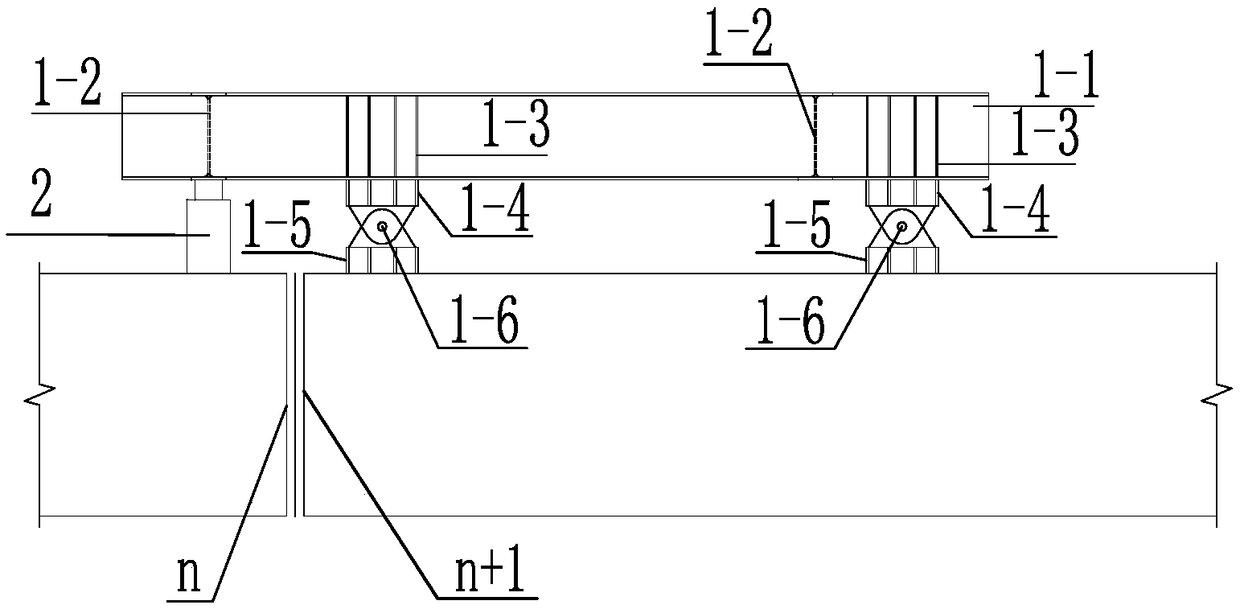

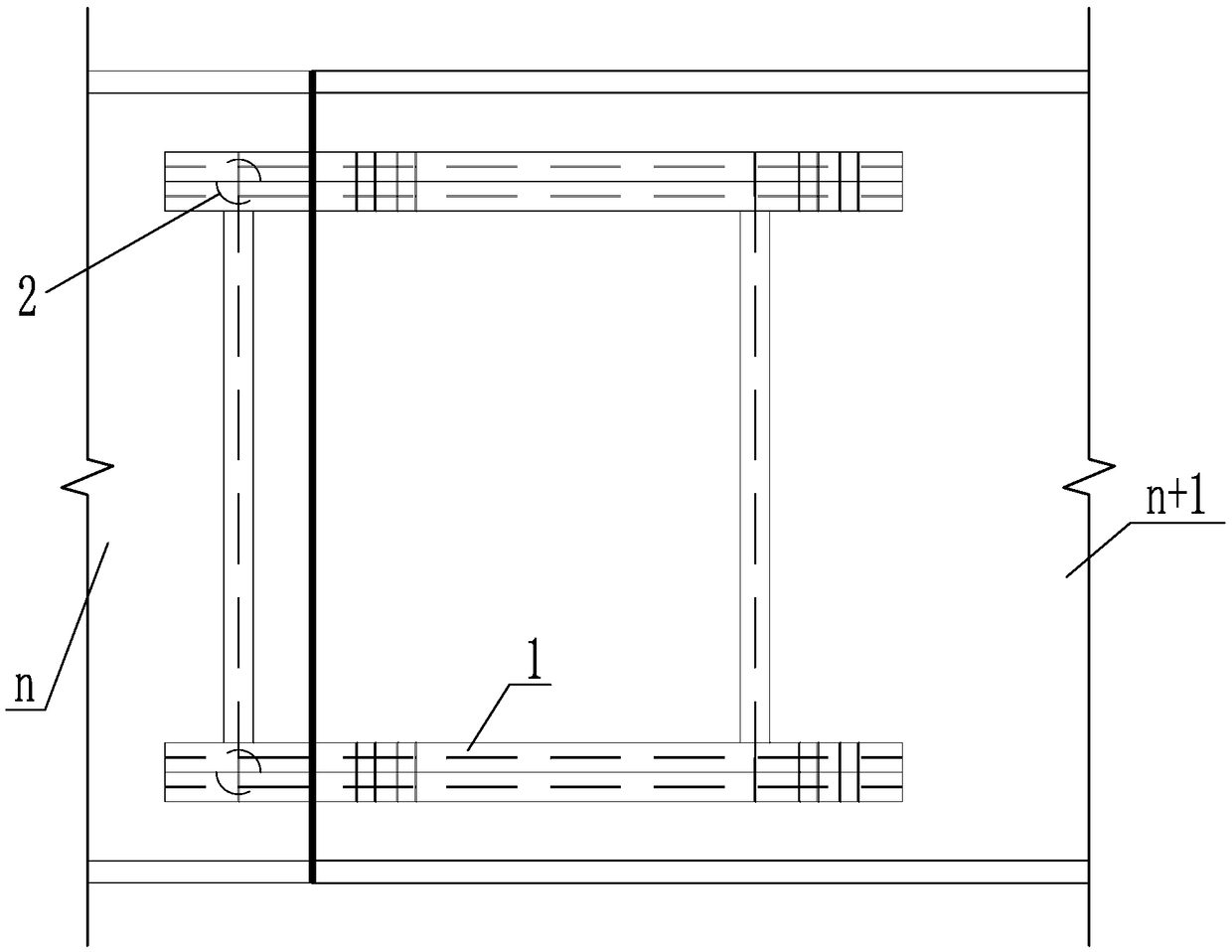

[0067] Such as Figure 1 to Figure 18 As shown, it is a temporary structure for installation of a continuous steel girder bridge in the present invention, including a hanger 1 and a displacement adjustment device 2, and the hanger 1 acts on the displacement adjustment device 2.

[0068] The displacement adjustment device 2 includes a single vertical jack 2-1, three horizontal jacks 2-2, a reaction force seat 2-3, a limit groove 2-5 and a bridge top steel backing plate 2-8. Two transverse jacks 2-2 arranged symmetrically to each other are arranged along the X-axis direction of the installed beam section, and a single transverse jack 2-2 is arranged along the Y-axis direction of the installed beam section. The force base 2-3 is welded and fixed; the vertical jack 2-1 is set along the Z-axis direction of the installed beam section, and the vertical jack 2-1 is set in the limiting groove 2-5. The bottom surface of the limiting groove 2-5 is welded with the steel backing plate 2-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com