Assembly-type prefabricated concrete checking well and construction method thereof

A prefabricated concrete and inspection well technology, which is applied to water supply devices, waterway systems, drainage structures, etc., can solve the problems that prefabricated inspection wells are difficult to popularize and use, difficult to ensure tightness, and irreconcilable, and achieve good tightness and assembly. Accuracy, effective sealing, stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

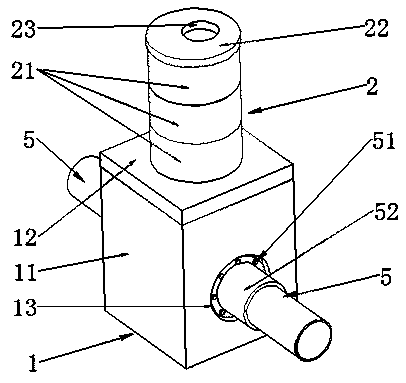

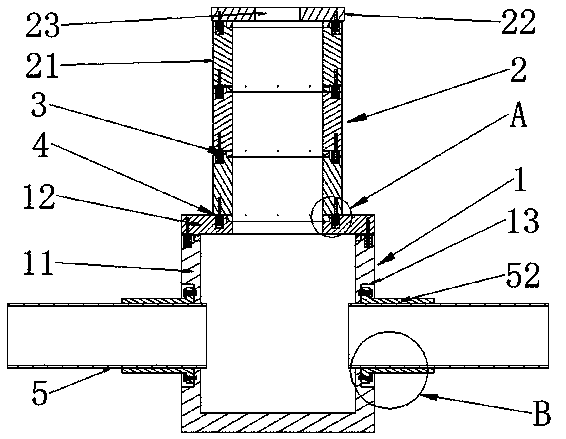

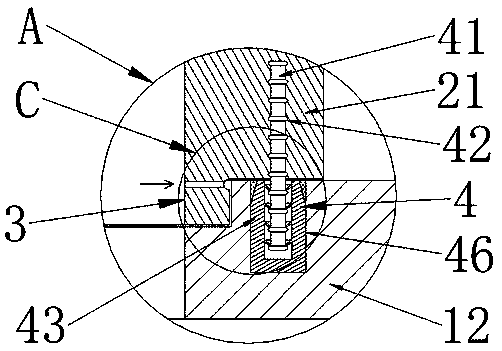

[0041] see Figure 1-6 , an assembled prefabricated concrete inspection well, comprising a well chamber main body 1 and a shaft main body 2 fixed above the well chamber main body 1; the well chamber main body 1 includes a lower well chamber 11 with a bottom plate and a well chamber cover plate 12; The upper end of the lower well chamber 11 is open, and the well chamber cover plate 12 is fixed on the upper end of the lower well chamber 11; the side wall of the lower well chamber 11 is provided with a plurality of pipe reserved holes 13 for installing the access pipe 5 A number of fixing seats 52 are sleeved outside the access pipe 5; one end of the fixing seats 52 close to the lower well chamber 11 is fixed with a flange end 53 along the outer wall surface, and a number of fixing bolts 51 pass through the flange end 53, the fixing seat 52 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com