Curved wood member chain plate type steel clamping plate connecting joint and construction method thereof

A technology for connecting nodes and wooden components, applied in building structures, buildings, etc., can solve problems such as brittle transverse cracks, and achieve the effects of reducing transverse cracking stress, avoiding transverse cracking, and quick and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

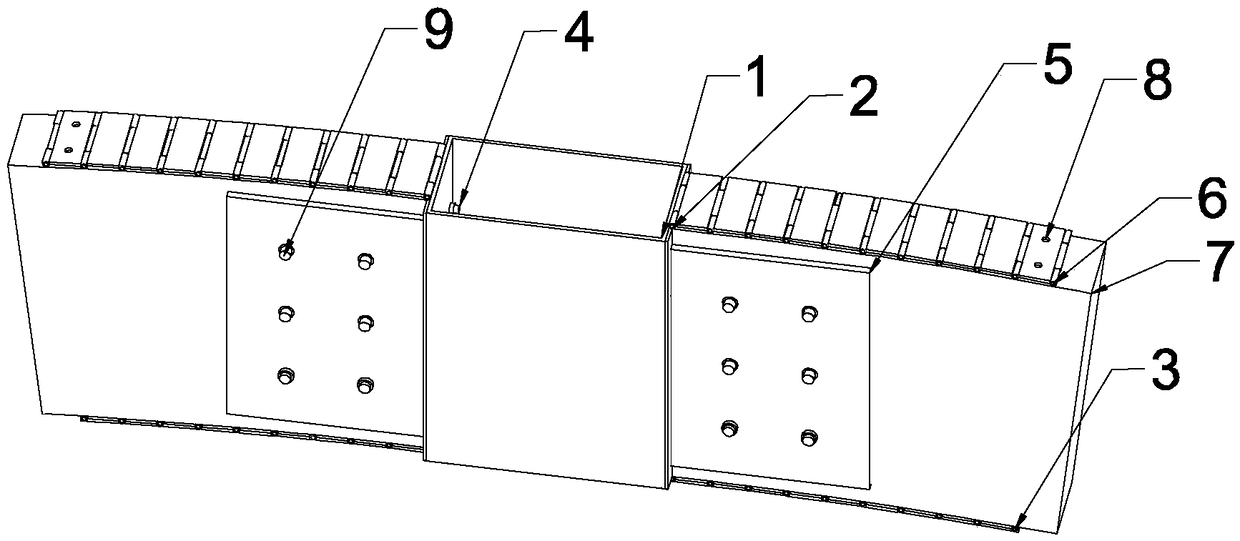

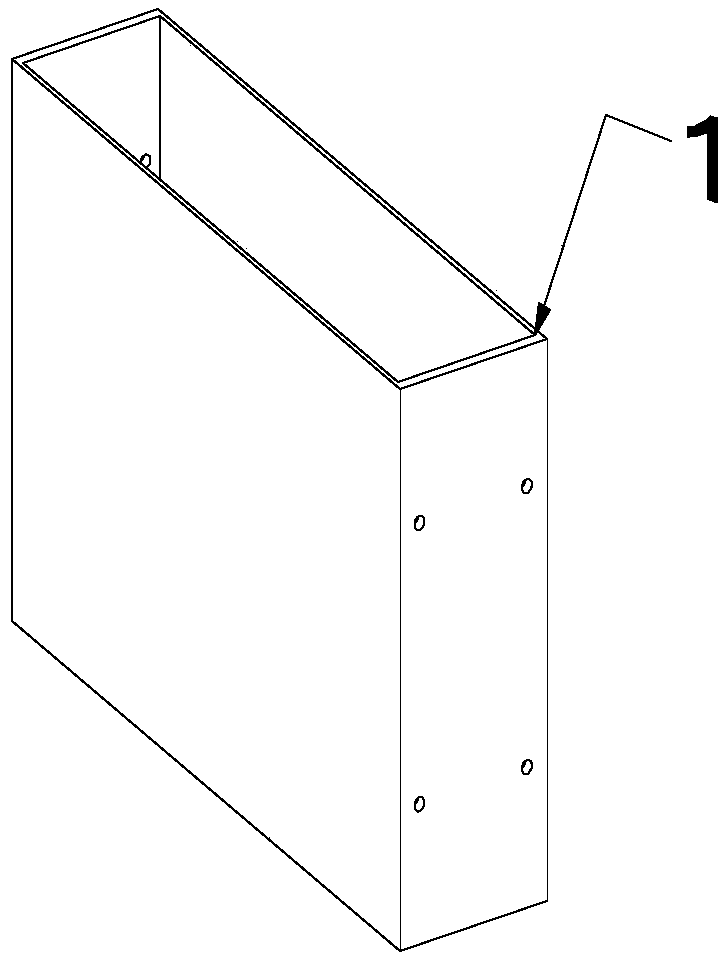

[0025] Specific implementation mode one: combine Figure 1-Figure 10 Describe this embodiment, a curved wooden member chain plate type steel splint connection node described in this embodiment, it includes two curved wooden members 7, it also includes a steel hub 1, two connecting plates 2, and four steel splints 5. A plurality of chain plates 3 and a plurality of pins 6; the steel hub 1 is a rectangular pipe body, and two connecting plates 2 are vertically fixedly installed on the outer walls of both sides of the steel hub 1, and the two sides of each connecting plate 2 are respectively A steel splint 5 is provided, and the steel splint 5 is fixedly welded and installed on the outer wall of the steel hub 1, and a curved wooden member 7 is arranged between the two steel splints 5 on the same side of the steel hub 1, and the curved wooden member 7 is fixedly installed on two steel splints 5, the upper surface and the lower surface of the curved wooden member 7 are respectively ...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. In this embodiment, a curved wooden component chain-plate type steel splint connection node is described. A plurality of through holes are respectively processed on both sides of the steel hub 1 . Other methods are the same as in the first embodiment.

specific Embodiment approach 3

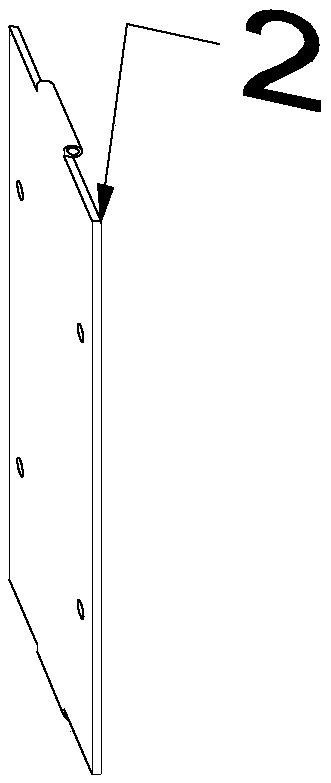

[0027] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, a kind of curved wooden component chain plate type steel splint connection node in this embodiment, the connection plate 2 is a rectangular plate body, and the two ends of the rectangular plate body are respectively equipped with cylindrical connecting parts, and the rectangular plate body is processed There are holes corresponding to steel hub 1. Other methods are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com