Waterproof roll laying device for building

A waterproof roll material and laying device technology, which is applied in building insulation materials, building material processing, construction, etc., can solve problems such as loose connection, water leakage, and inability to guarantee the level, and achieve waterproof performance, simple operation, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

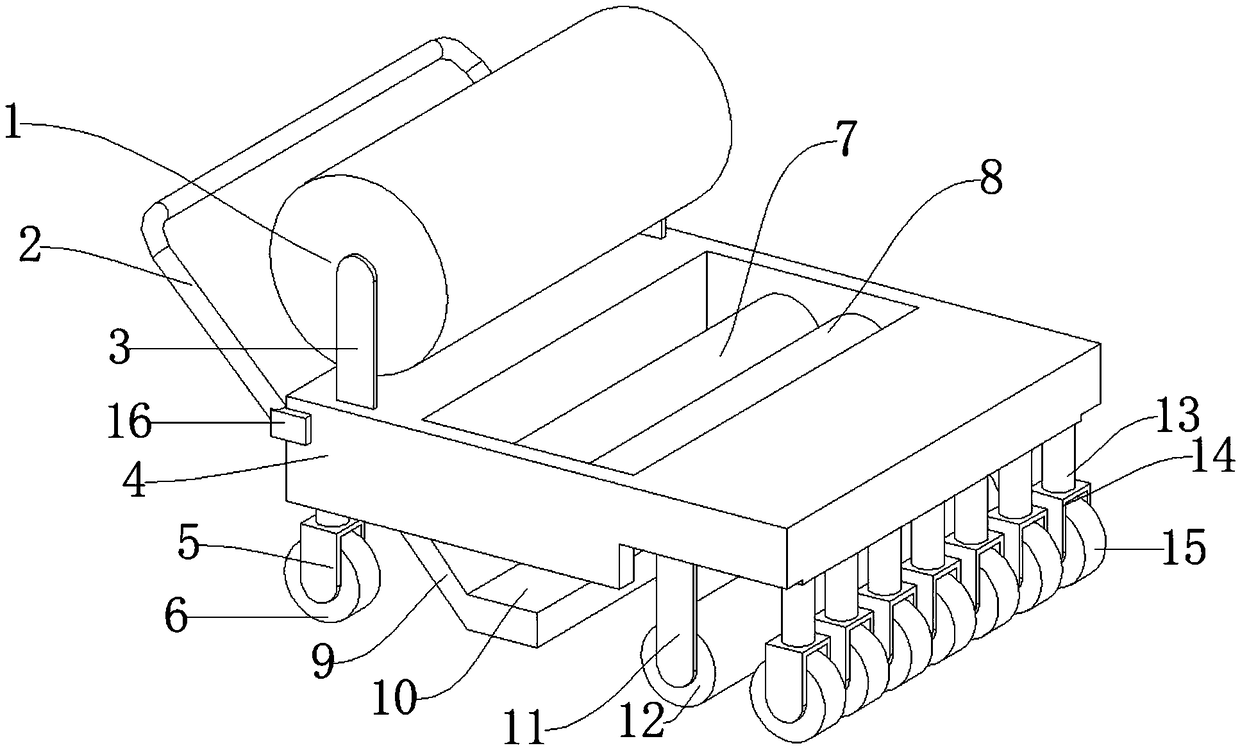

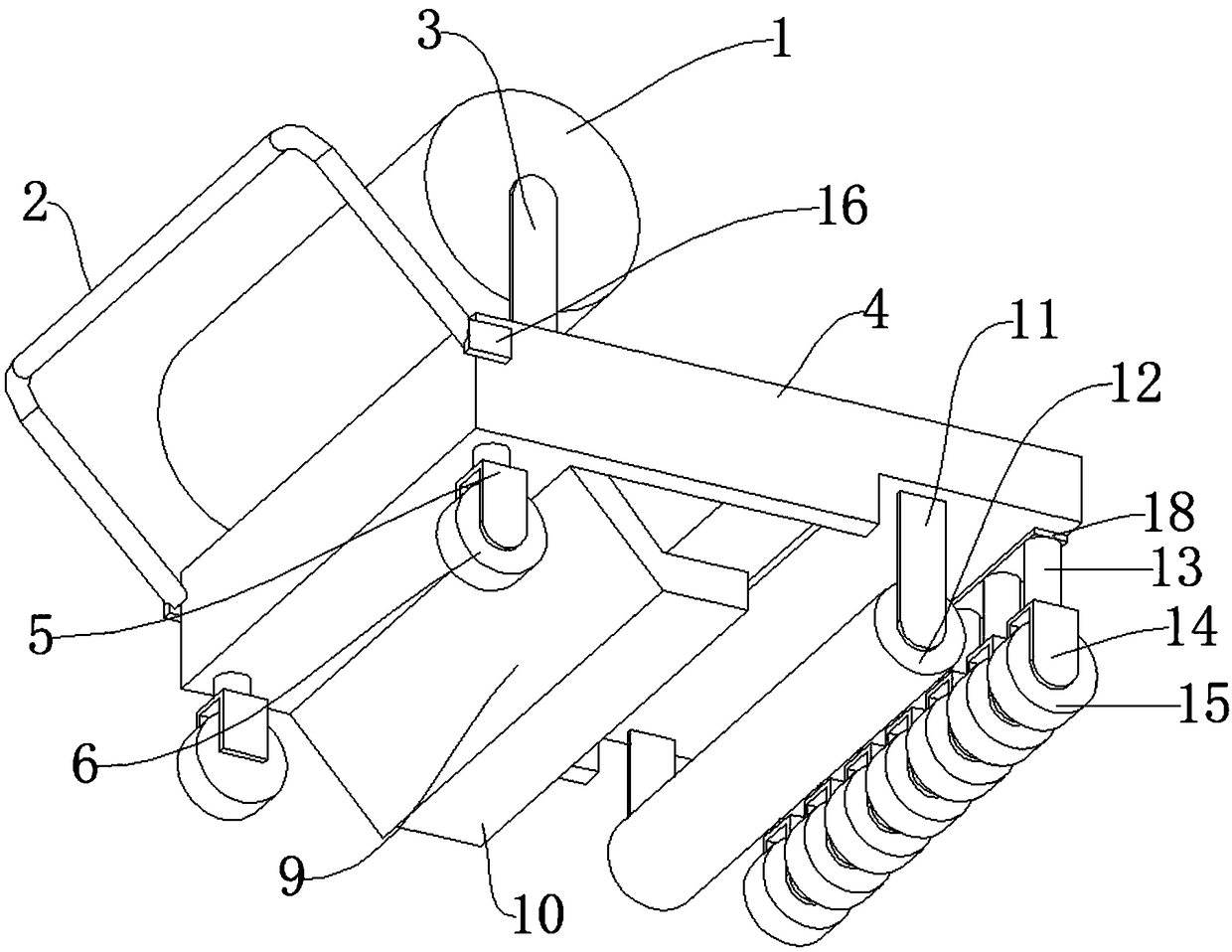

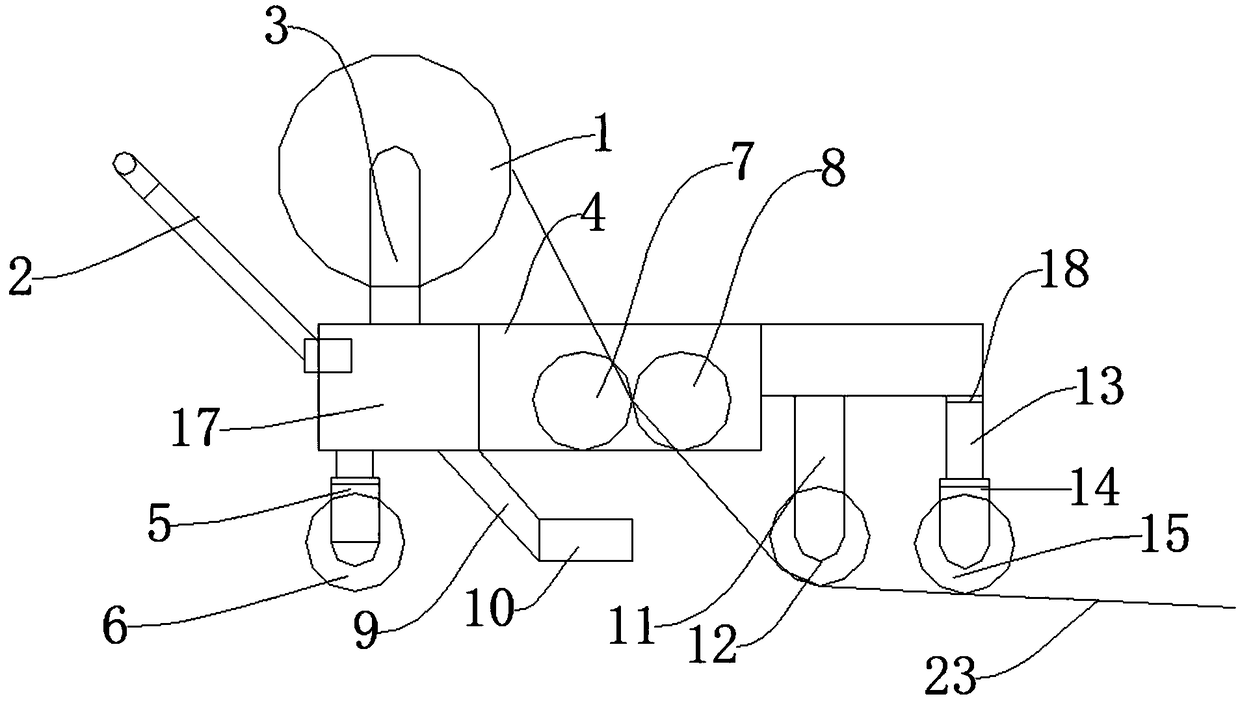

[0039] Such as Figure 1-Figure 4 As shown, a waterproof coiled material laying device for construction includes a coiled material tube 1, a handrail 2, a vehicle frame 4, and a telescopic mechanism 13. Both sides of the vehicle frame 4 are provided with armrest adjustment seats 16, and the vehicle frame 4 plays a load-bearing role. The adjustment seat 16 plays a regulating role, and the armrest adjustment seat 16 is connected to the vehicle frame 4 by bolts. The rear end of the armrest adjustment seat 16 is provided with an armrest 2, and the armrest 2 plays a role in moving. The armrest 2 is connected to the armrest adjustment seat 16 by bolts, and the vehicle frame 4 The upper end is provided with a reel support frame 3, and the reel support frame 3 plays a supporting role. The reel support frame 3 is connected to the vehicle frame 4 through bolts. Function, the coiled material drum 1 is rotatably connected to the drum support frame 3, the coiled material drum 1 is provided...

Embodiment 2

[0041] Such as Figure 1-Figure 4As shown, a waterproof coiled material laying device for construction includes a coiled material tube 1, a handrail 2, a vehicle frame 4, and a telescopic mechanism 13. Both sides of the vehicle frame 4 are provided with armrest adjustment seats 16, and the vehicle frame 4 plays a load-bearing role. The adjustment seat 16 plays a regulating role, and the armrest adjustment seat 16 is connected to the vehicle frame 4 by bolts. The rear end of the armrest adjustment seat 16 is provided with an armrest 2, and the armrest 2 plays a role in moving. The armrest 2 is connected to the armrest adjustment seat 16 by bolts, and the vehicle frame 4 The upper end is provided with a reel support frame 3, and the reel support frame 3 plays a supporting role. The reel support frame 3 is connected to the vehicle frame 4 through bolts. Function, the coiled material drum 1 is rotatably connected to the drum support frame 3, the coiled material drum 1 is provided ...

Embodiment 3

[0043] Such as Figure 1-Figure 4 As shown, a waterproof coiled material laying device for construction includes a coiled material tube 1, a handrail 2, a vehicle frame 4, and a telescopic mechanism 13. Both sides of the vehicle frame 4 are provided with handrail adjustment seats 16, and the vehicle frame 4 plays a load-bearing role. The adjustment seat 16 plays a regulating role, and the armrest adjustment seat 16 is connected to the vehicle frame 4 by bolts. The rear end of the armrest adjustment seat 16 is provided with an armrest 2, and the armrest 2 plays a role in moving. The armrest 2 is connected to the armrest adjustment seat 16 by bolts, and the vehicle frame 4 The upper end is provided with a reel support frame 3, and the reel support frame 3 plays a supporting role. The reel support frame 3 is connected to the vehicle frame 4 through bolts. Function, the coiled material drum 1 is rotatably connected to the drum support frame 3, the coiled material drum 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com