Window shutter and production process thereof

A production process and blinds technology, which is applied in the field of blinds and windows, can solve the problems of window frame cracking, uneven assembly surface, high assembly surface, etc., and achieve the effect of simple production steps, simplified production steps and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

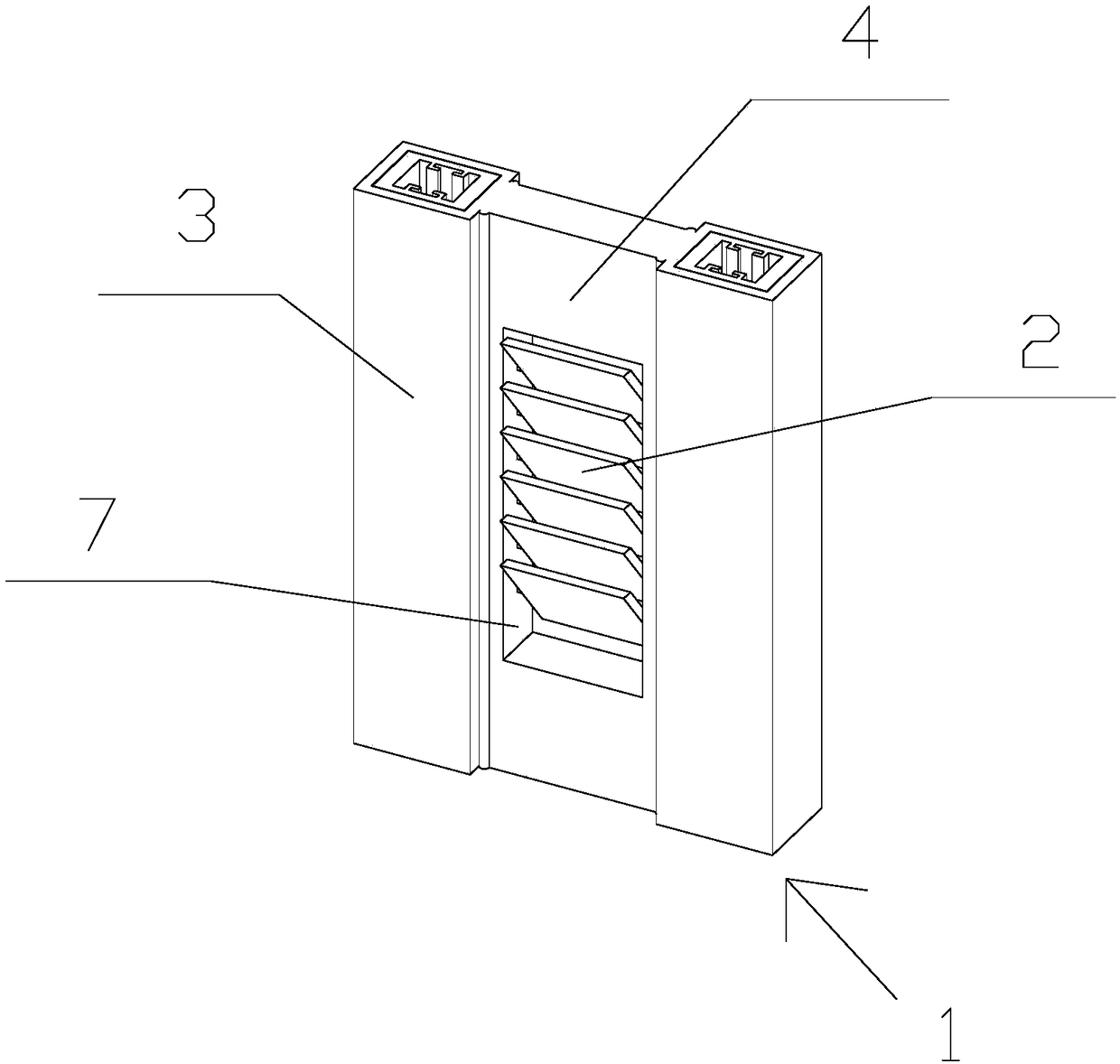

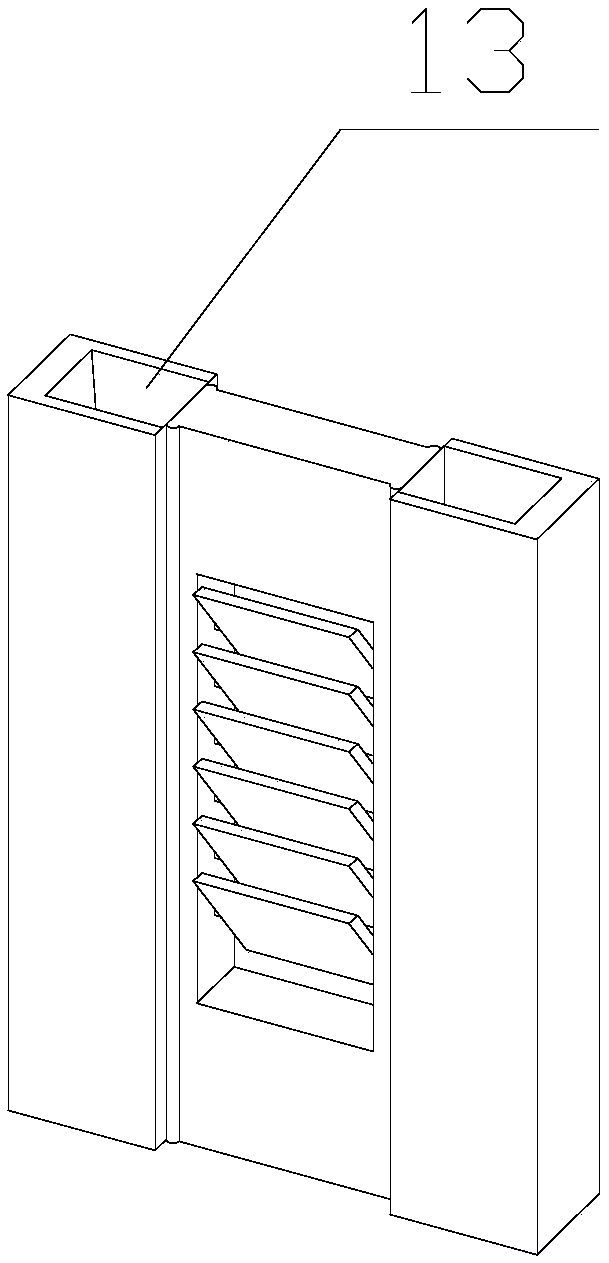

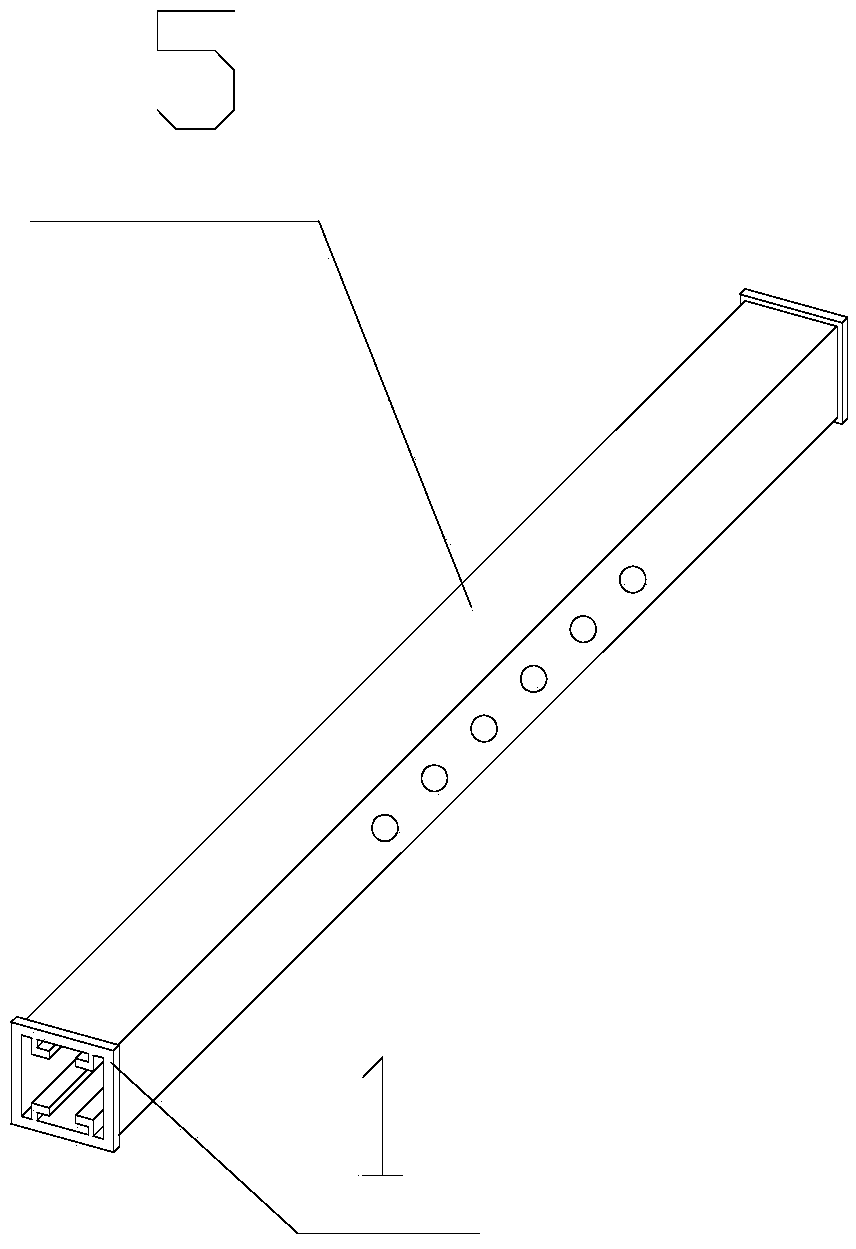

[0049] As shown in the figure, a shutter includes a window frame 1 and several blades 2, the window frame 1 includes a pair of support rods 3 and a pair of connecting rods 4, the inside of the support rods 3 is provided with a profile 5, at least one side of the profile 5 The inside is provided with a track 6 for fixing the rack 10, at least one side of the profile 5 is provided with a rack 10 inside, and the rack 10 can slide in the track 6 along the length direction of the track 6; the support rod 3 and the connecting rod 4 are spliced and formed The window part 7, several blades 2 are installed in the window part 7, the end shafts 8 are arranged on the blades 2, the blades 2 are mounted on the support rod 3 through the end shafts 8 and can rotate with the end shafts 8, and a rack 10 is provided The end shafts 8 on one side are all equipped with gears 9 meshing with the racks 10, and several blades 2 rotate in linkage under the action of external force.

[0050] The rack 1...

Embodiment 2

[0067] As shown in the figure, a shutter includes a window frame 1 and several blades 2, the window frame 1 includes a pair of support rods 3 and a pair of connecting rods 4, the inside of the support rods 3 is provided with a profile 5, at least one side of the profile 5 The inside is provided with a track 6 for fixing the rack 10, at least one side of the profile 5 is provided with a rack 10 inside, and the rack 10 can slide in the track 6 along the length direction of the track 6; the support rod 3 and the connecting rod 4 are spliced and formed The window part 7, several blades 2 are installed in the window part 7, the end shafts 8 are arranged on the blades 2, the blades 2 are mounted on the support rod 3 through the end shafts 8 and can rotate with the end shafts 8, and a rack 10 is provided The end shafts 8 on one side are all equipped with gears 9 meshing with the racks 10, and several blades 2 rotate in linkage under the action of external force.

[0068] The rack 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com