Channeling-free deep hole blasting shaft forming process

A technology of groove depth and craftsmanship, applied in blasting, earth-moving drilling, underground transportation, etc., can solve the problems of difficult discharge of blasting smoke, difficulty in blasting, and large amount of dredging works, so as to reduce the probability of hole plugging and reduce the number of holes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

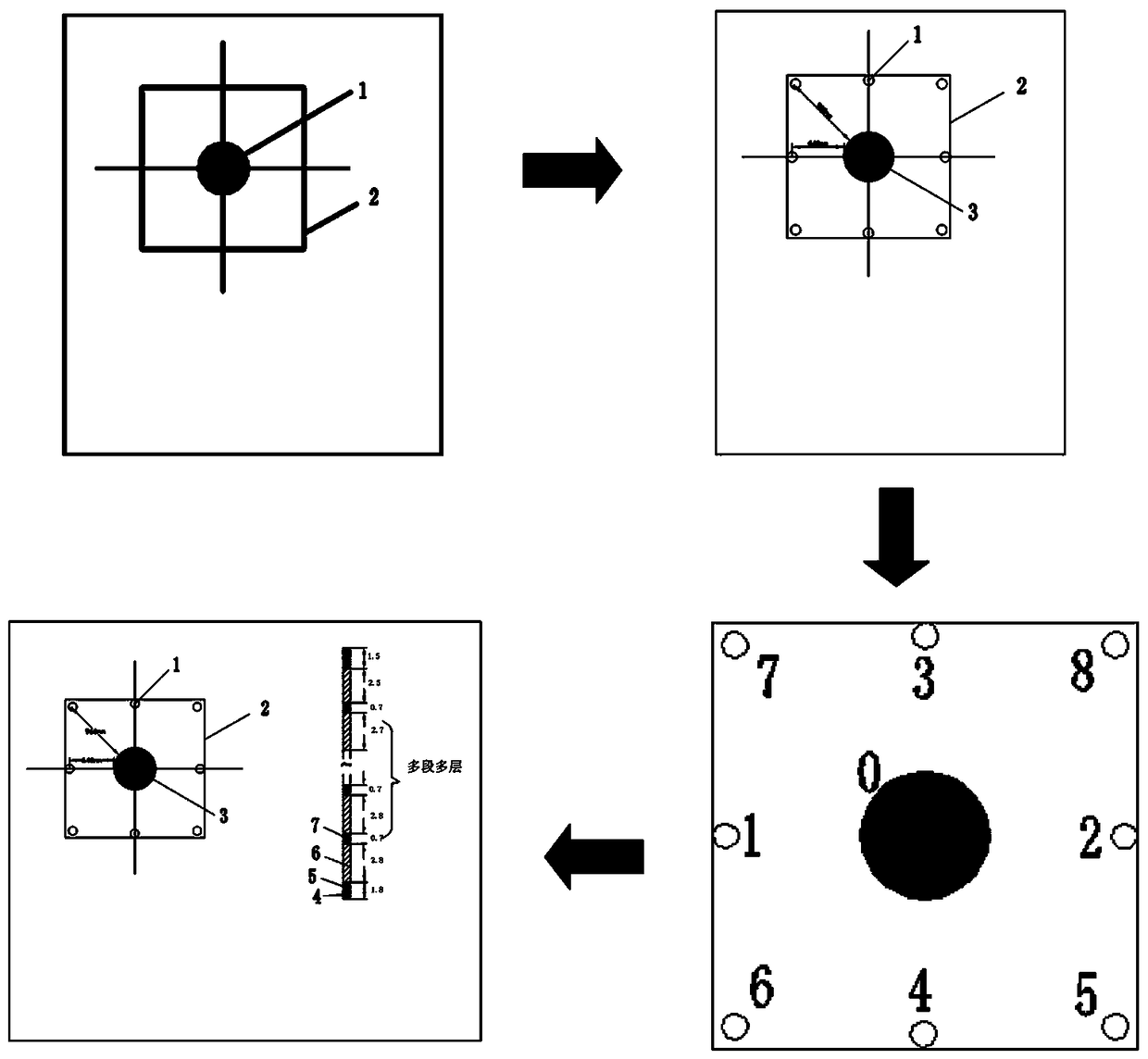

[0024] Aiming at the importance of the shaft in the roadway project of Yichang Phosphate Mine and the characteristics of low safety, poor working environment, slow dissipation of the blast hole and poor ventilation in the construction process of the high shaft with the common method. Combining the advantages of the deep hole blasting and cutting method of the high-speed shaft, it is further optimized in reducing the number of holes, reducing the blockage of the blast hole and the difficulty of ventilation, so as to ensure the safety and high efficiency of the first-time well completion.

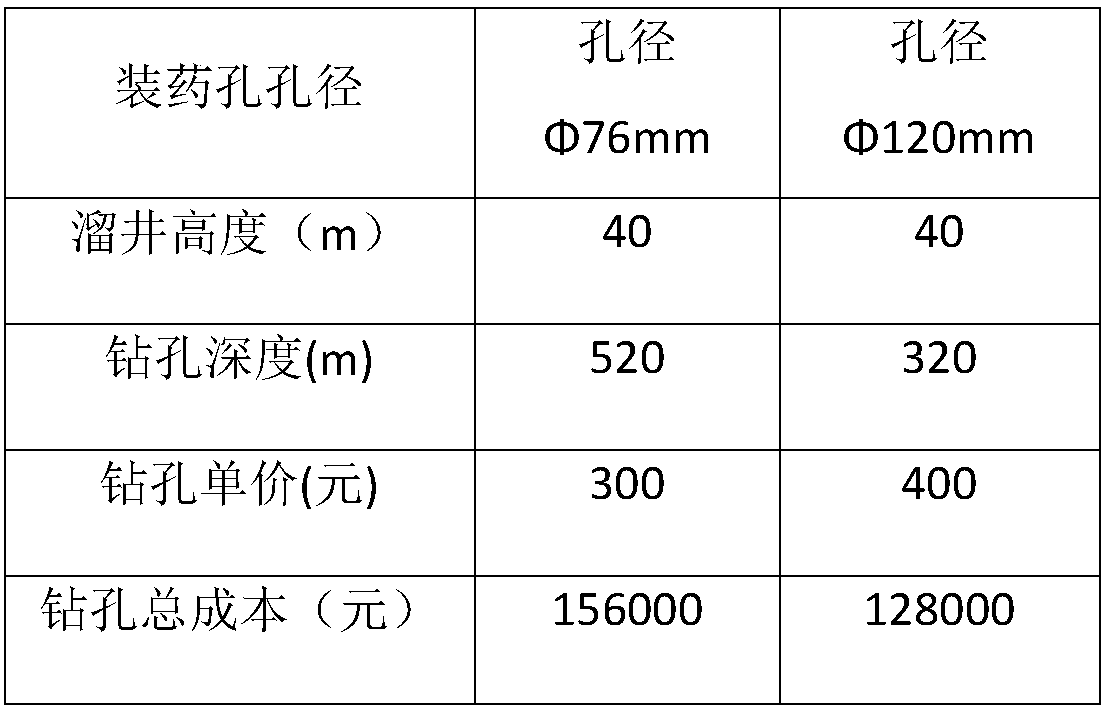

[0025] Drill one Φ600 hollow hole along the center of the section, and drill 8 Φ120 charging holes at equal intervals along the periphery of the section (76mm charging holes can also be used, but the cost is higher and give up), and the half-second delay detonation tube is adopted. Delayed blasting.

[0026]

[0027] All drilling holes must be parallel and the deflection rate shall not exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com