Safety analysis method for gearbox gears of heavy haul vehicles

An analysis method and transmission technology, applied in the safety analysis field of heavy-duty vehicle systems considering index correlation and redundancy, can solve the problem of interpretable results, weak traceability, inability to integrate qualitative and quantitative information, reducing Evaluation accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

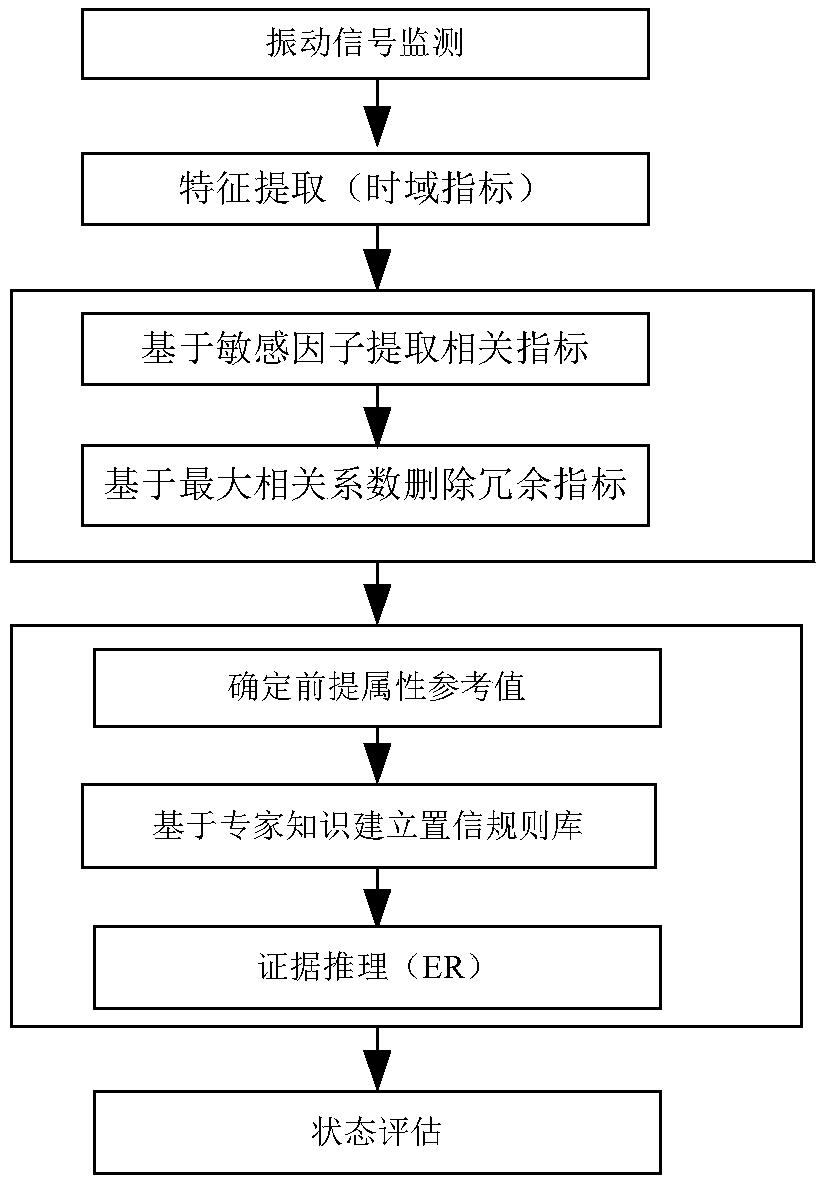

[0064] The procedure of this method is as follows figure 1 As shown, it mainly includes the following steps:

[0065] Step 1: Acquisition and processing of heavy-duty vehicle gearbox gear vibration signals

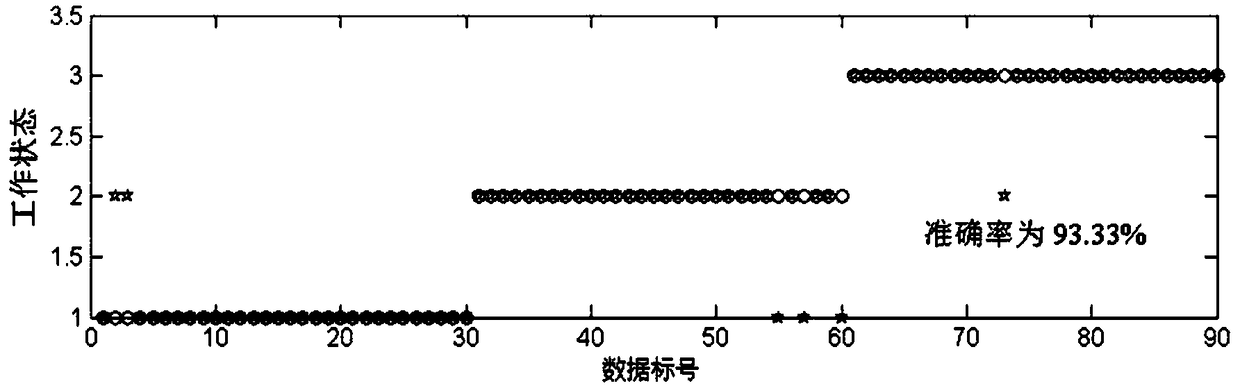

[0066] Place two sensors on the transmission case next to the gears. The acceleration sensor uses the American Dytran 3023M2 (three-way) general-purpose acceleration sensor with a sensitivity of ±10mv / g. Each sensor measures vibration signals in horizontal, vertical and vertical directions. The data sampling frequency is 25600Hz. There are three working states of the gear: one is the normal working state; the other is the gear crack; the third is the gear peeling off.

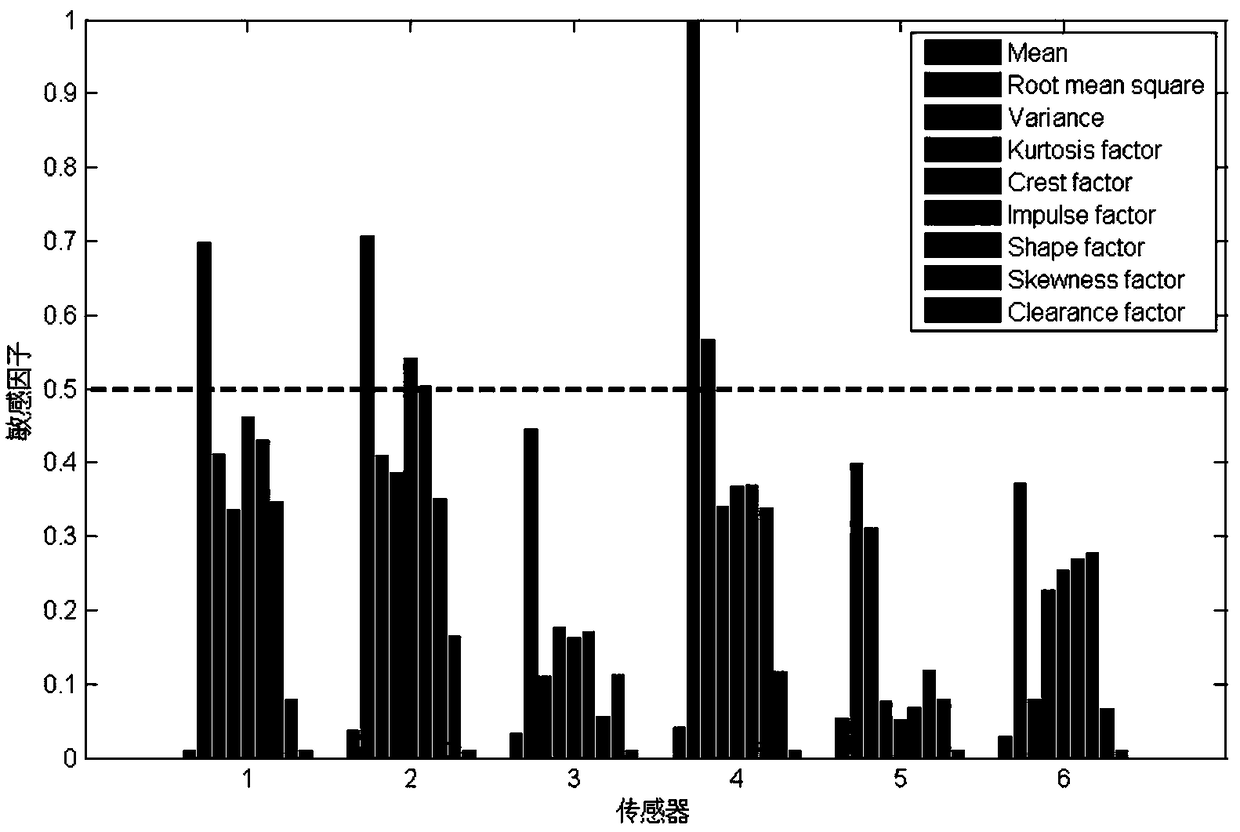

[0067] The present invention altogether measures 6 groups of vibration signals, which are respectively the x, y, and z direction signals measured by sensors 1 and 2. Each group of vibration signals extracts 9 time-domain indicators, so there are 54 time-domain indicators to reflect the state of the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com