Liquid adsorbent testing method

A technology of liquid adsorbent and testing method, which is applied in the direction of electromagnet, material absorption weighing, electromagnetic circuit device, etc., which can solve the problems of weighing result error, affecting the stability of the electromagnet magnetic field, etc., and achieve the effect of stabilizing the working current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

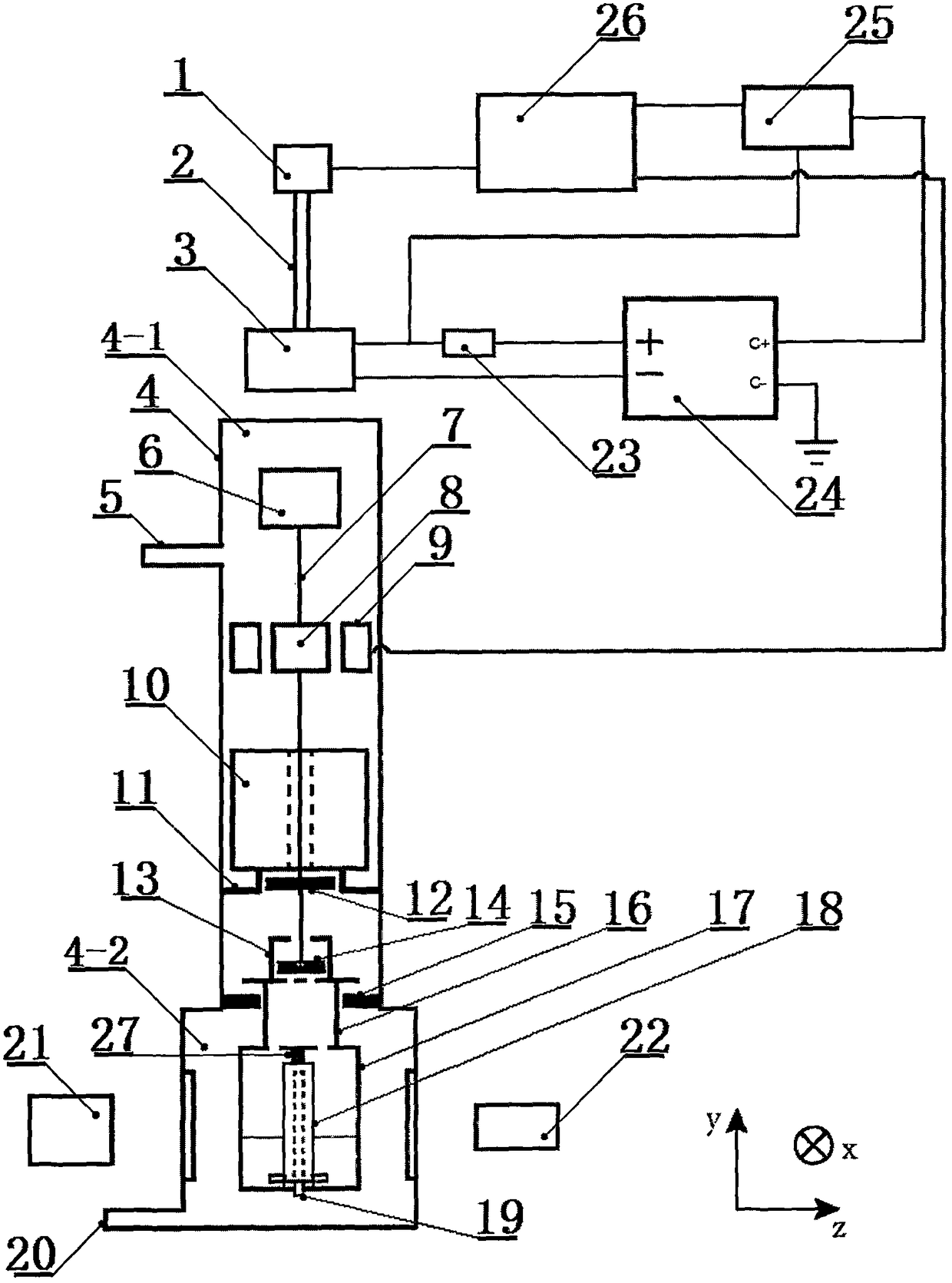

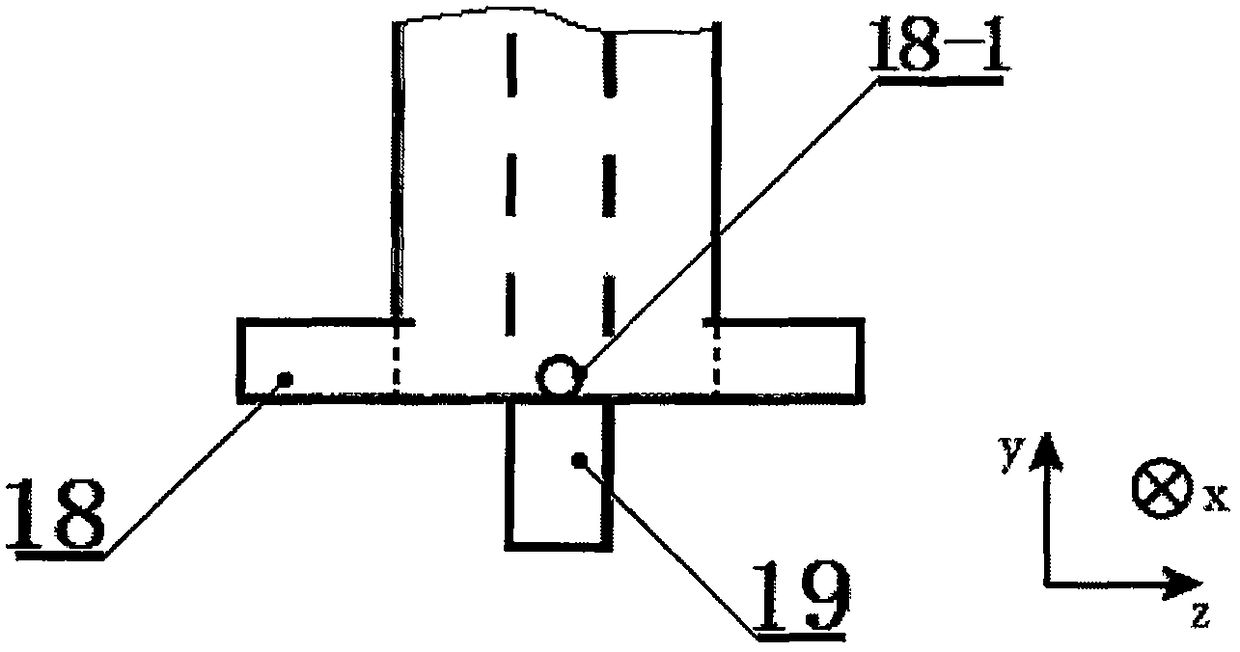

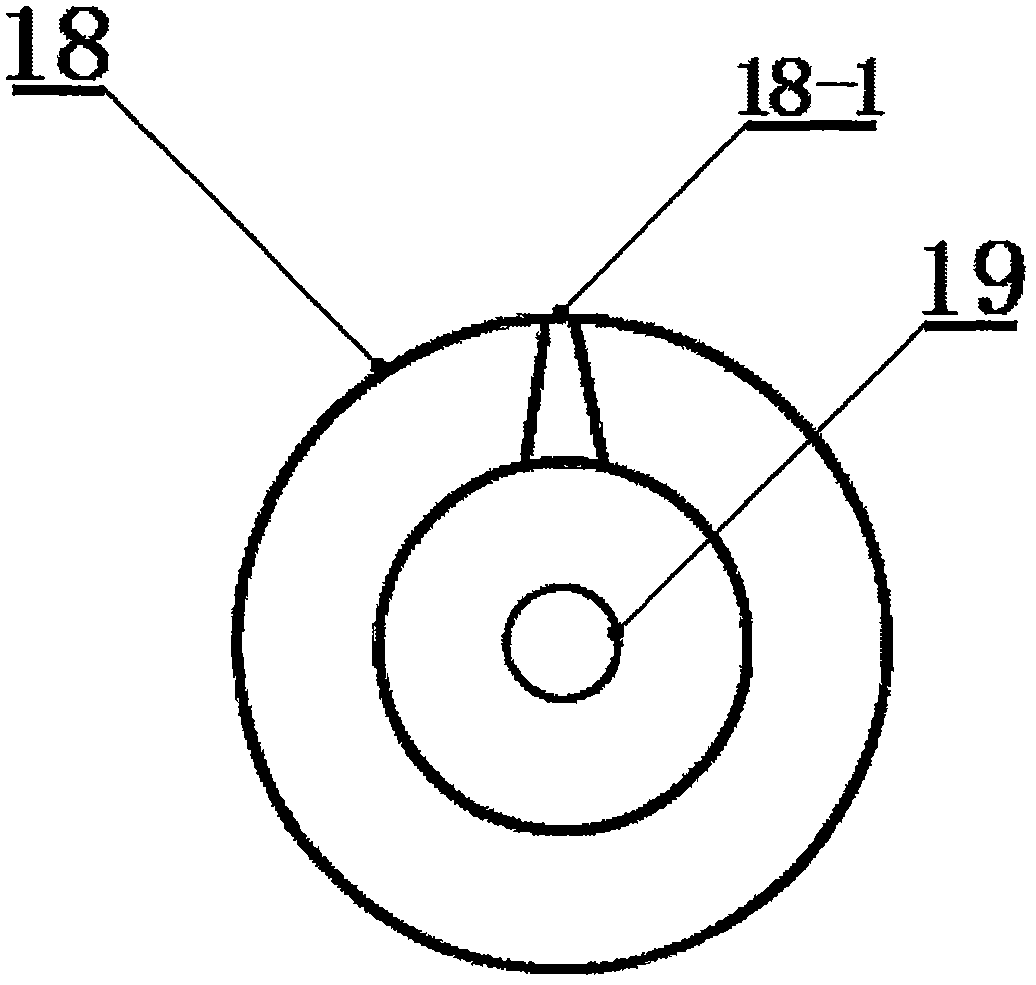

[0038] Such as figure 1 It is a schematic diagram of the present invention, and xyz is a three-dimensional space coordinate system, including a microbalance (1), a suspension rod (2), an electromagnet (3), a test chamber (4), an air vent I (5), a permanent magnet (6), Steel wire (7), displacement sensor (8), induction coil (9), standard sample (10), support position I (11), tray I (12), bracket (13), tray II (14), support Position II (15), connecting pipe (16), sample chamber (17), air pipe I (18), air pipe II (19), vent II (20), light source (21), camera (22), voltage divider resistor (23), DC power supply (24), feedback circuit (25), computer (26) and displacement platform (27), microbalance (1) connects computer (26), feedback circuit (25) connects computer (26), test The cavity (4) includes cavity I (4-1) and cavity II (4-2) connected from top to bottom, the position of the microbalance (1) is fixed, and the electromagnet (3) is connected to the microbalance through the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com