Full-automatic line production equipment for moisture content measurement

A technology of assembly line operation and water content, which is applied to measuring devices, by removing certain components, weighing, instruments, etc., can solve the problems of increasing test errors and increasing labor costs, so as to achieve improved accuracy, reasonable structural design, and avoid The effect of misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

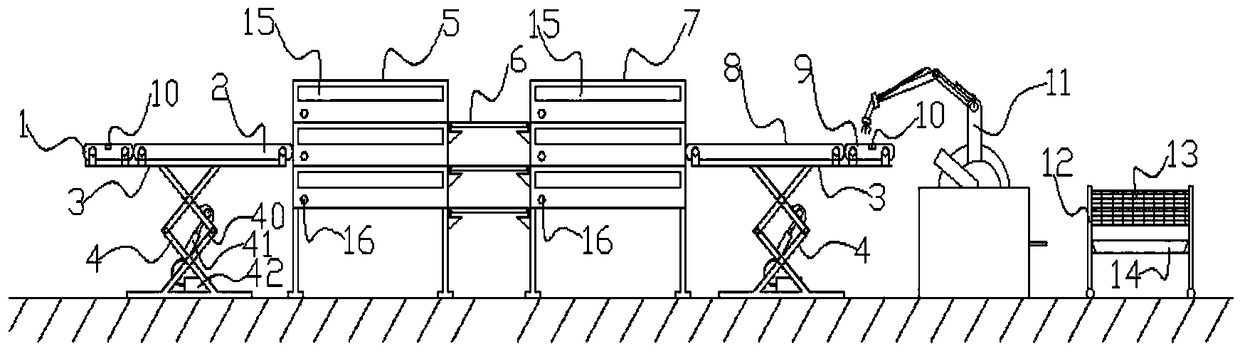

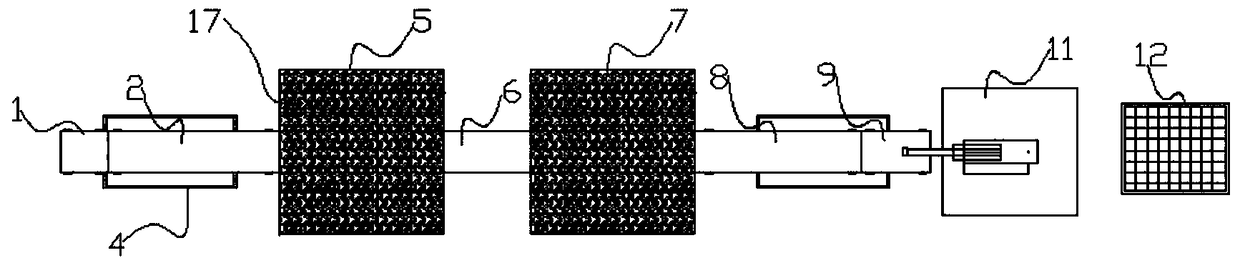

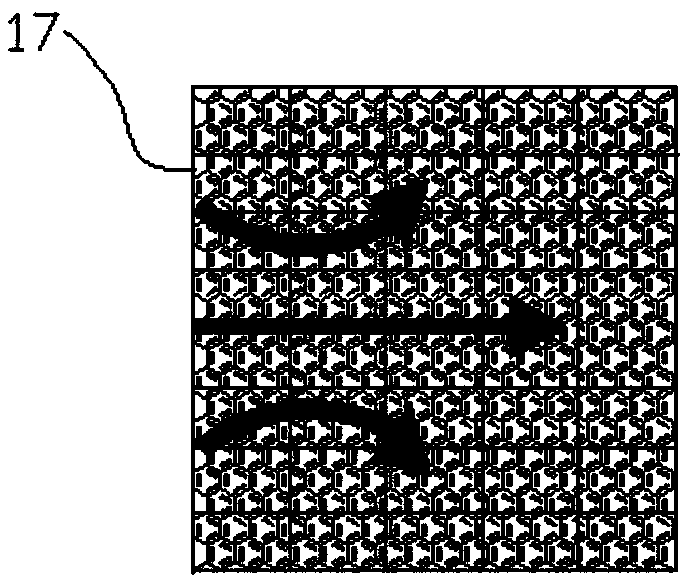

[0023] Such as Figure 1-5 As shown, the present invention discloses a fully automatic measuring water content flow-water operation equipment, including a conveyor belt component 1, a conveyor belt component 2 2, a hydraulic lifting platform 3, a hydraulic lifting device 4, a constant temperature drying cabin 5, a conveyor belt component 3 6, Cooling and drying cabin 7, conveyor belt assembly four 8, conveyor belt assembly five 9, mechanical hand loading 11, drying tooling 12, the conveyor belt assembly one 1 is arranged on the left side of the conveyor belt assembly two 2, and the conveyor belt assembly one 1 and the conveyor belt The second component 2 is fixedly installed on the hydraulic lifting platform 3, and the bottom surface of the hydraulic lifting platform 3 is fixedly provided with a hydraulic lifting device 4 to support and fix it.

[0024] The right side of the second conveyor belt assembly 2 is provided with a constant temperature drying chamber 5 and a cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com