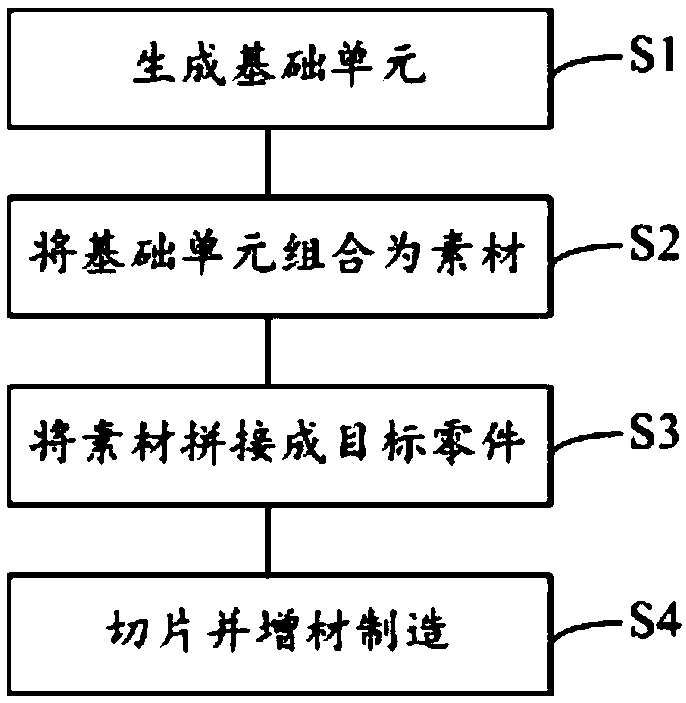

A part manufacturing method and device based on modularization

A modular and parts technology, applied in the field of parts manufacturing, can solve the problems of lack of specialization of special parts, reduce personal independent creation results and environmental atmosphere, and affect the independent creation process, so as to achieve high flexibility and reduce manufacturing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

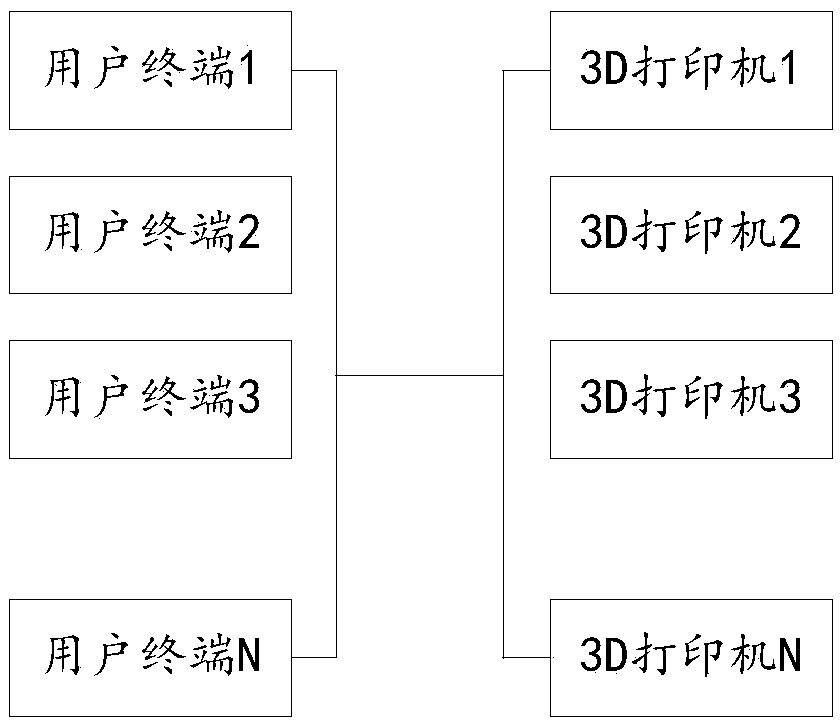

[0042] Embodiment 1: A kind of component manufacturing device based on modularization, such as figure 2 As shown, at least one user terminal and at least one 3D printer are included.

[0043] Each user terminal is used to custom-combine a plurality of said basic units into at least one material having a basic shape, generate a corresponding material file and store it for later use, and select a plurality of required materials to splice into a complete target part, Generating and storing the target part file, slicing the target part file, generating instruction code and sending it out.

[0044] Each 3D printer is used to receive the instruction code sent by the user terminal, and perform additive manufacturing according to the instruction code to obtain the product of the target part.

[0045] When working, the user drags the basic unit in the virtual space of the user terminal to freely assemble the target part model, performs slicing in the user terminal, and finally sends ...

Embodiment 2

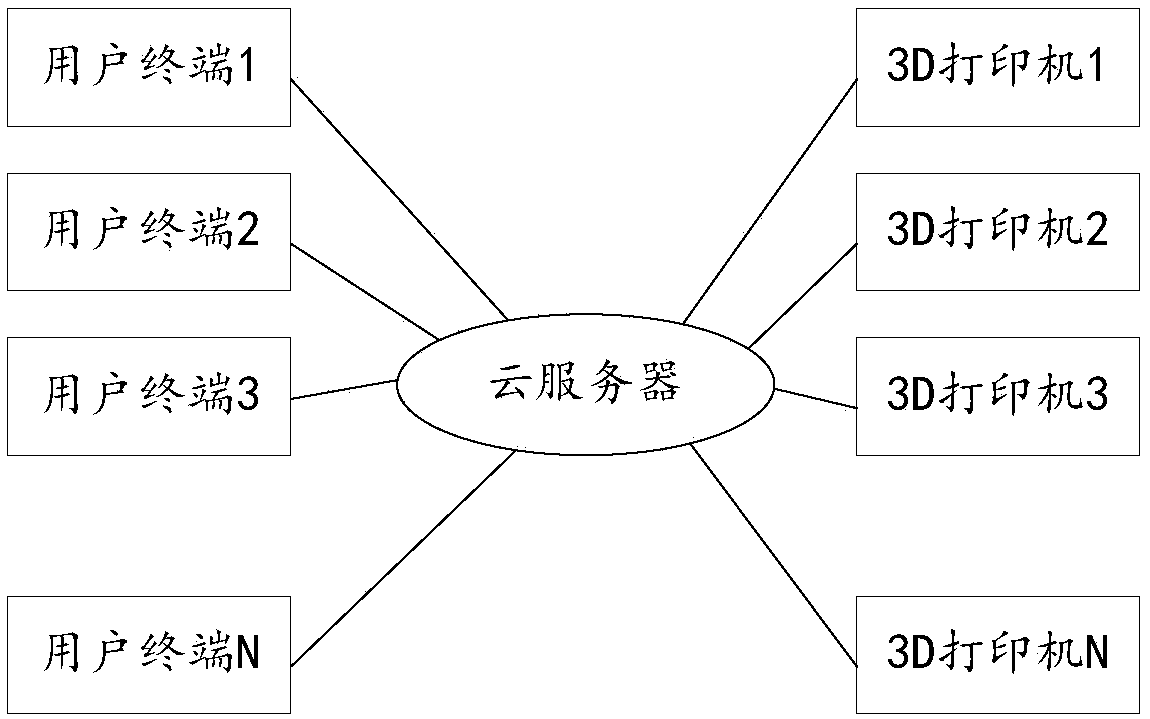

[0048] Embodiment 2: A kind of parts manufacturing device based on modularization, such as image 3 As shown, it includes at least one user terminal, a cloud server and at least one 3D printer.

[0049]Each user terminal is used to custom-combine a plurality of said basic units into at least one material having a basic shape, generate a corresponding material file and store it for later use, and select a plurality of required materials to splice into a complete target part, Generate the target part file and save it and send it out.

[0050] The cloud server is used to receive and store the target part file, slice the target part file, generate instruction code and send it out.

[0051] Each 3D printer is used to receive the instruction code sent by the cloud server, and implement additive manufacturing according to the instruction code to obtain the product of the target part.

[0052] When working, the user drags the basic unit in the virtual space of the user terminal to s...

Embodiment 3

[0053] Embodiment 3: A component manufacturing device based on modularization, including at least one user terminal, a cloud server and at least one 3D printer.

[0054] Each user terminal is used to custom-combine a plurality of said basic units into at least one material having a basic shape, generate a corresponding material file and store it for later use, and select a plurality of required materials to splice into a complete target part, Generate the target part file and save it and send it out.

[0055] Each 3D printer is used to receive the target part file, slice the target part file, generate an instruction code, and perform additive manufacturing according to the instruction code to obtain the product of the target part.

[0056] The cloud server is connected to the user terminal and the 3D printer for relaying the instruction code.

[0057] When working, the user drags the basic unit in the virtual space of the user terminal to freely assemble the target part model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com