Inductor turn-over mechanism

A technology of inductors and connecting rods, which is applied in coil manufacturing and other directions, can solve problems such as difficulty in ensuring the quality of inductors, achieve the effects of preventing breakage or loosening, facilitating welding, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

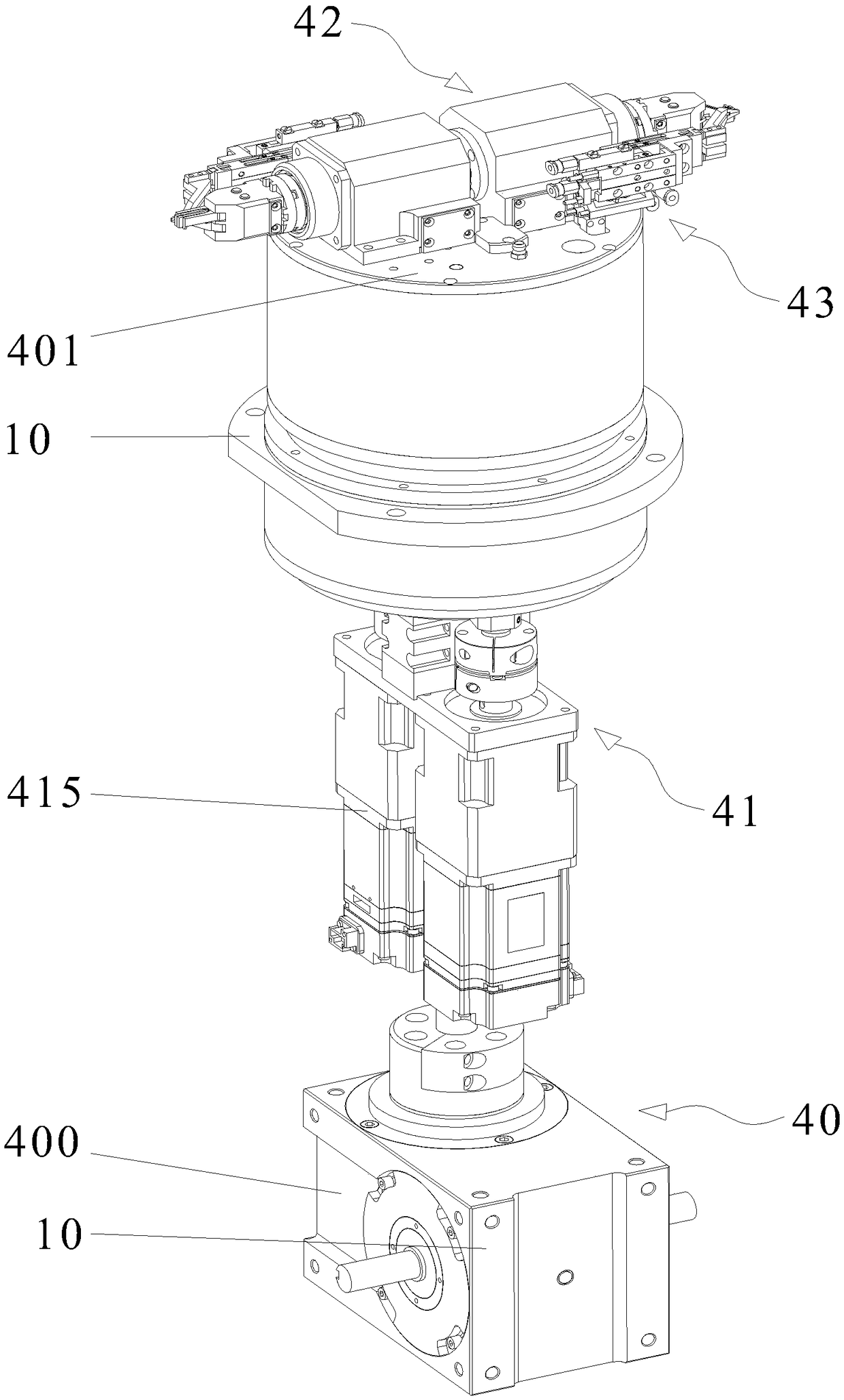

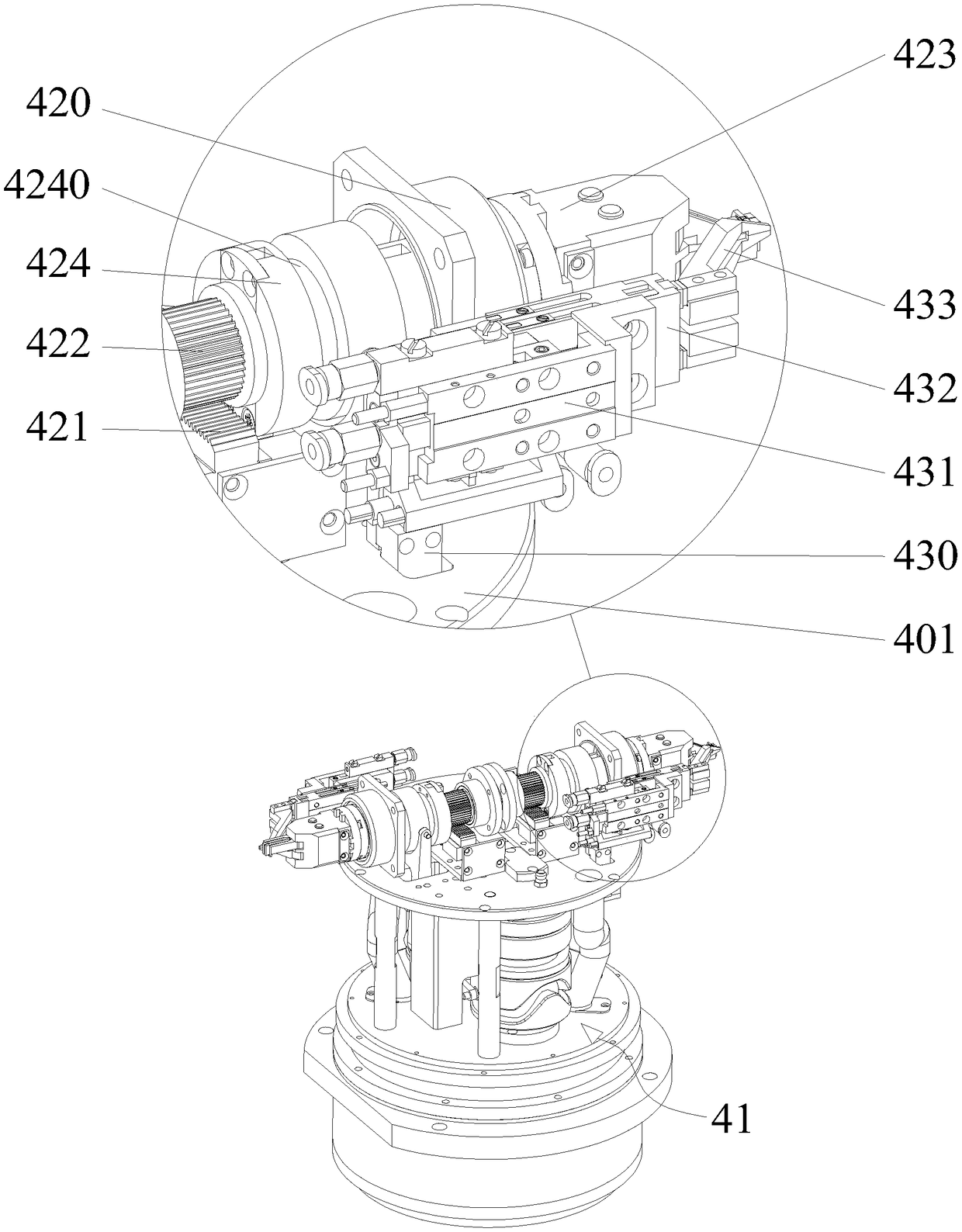

[0032] Reference Figure 1 ~ Figure 5 As shown, the present invention discloses an inductive turning mechanism, which includes a bracket 10 and a steering unit 40, a power unit 41, a turning clamping unit 42 and a wire clamping unit 43 arranged thereon.

[0033] Steering unit 40:

[0034] The above-mentioned steering unit 40 includes a steering drive source 400 and a steering platform 401 that are both arranged on the bracket 10. The steering platform 401 is connected to the free end of the steering driving source 400. The steering drive source 400 can drive the steering platform 401 to rotate, so that the inductance transfer station.

[0035] Power unit 41:

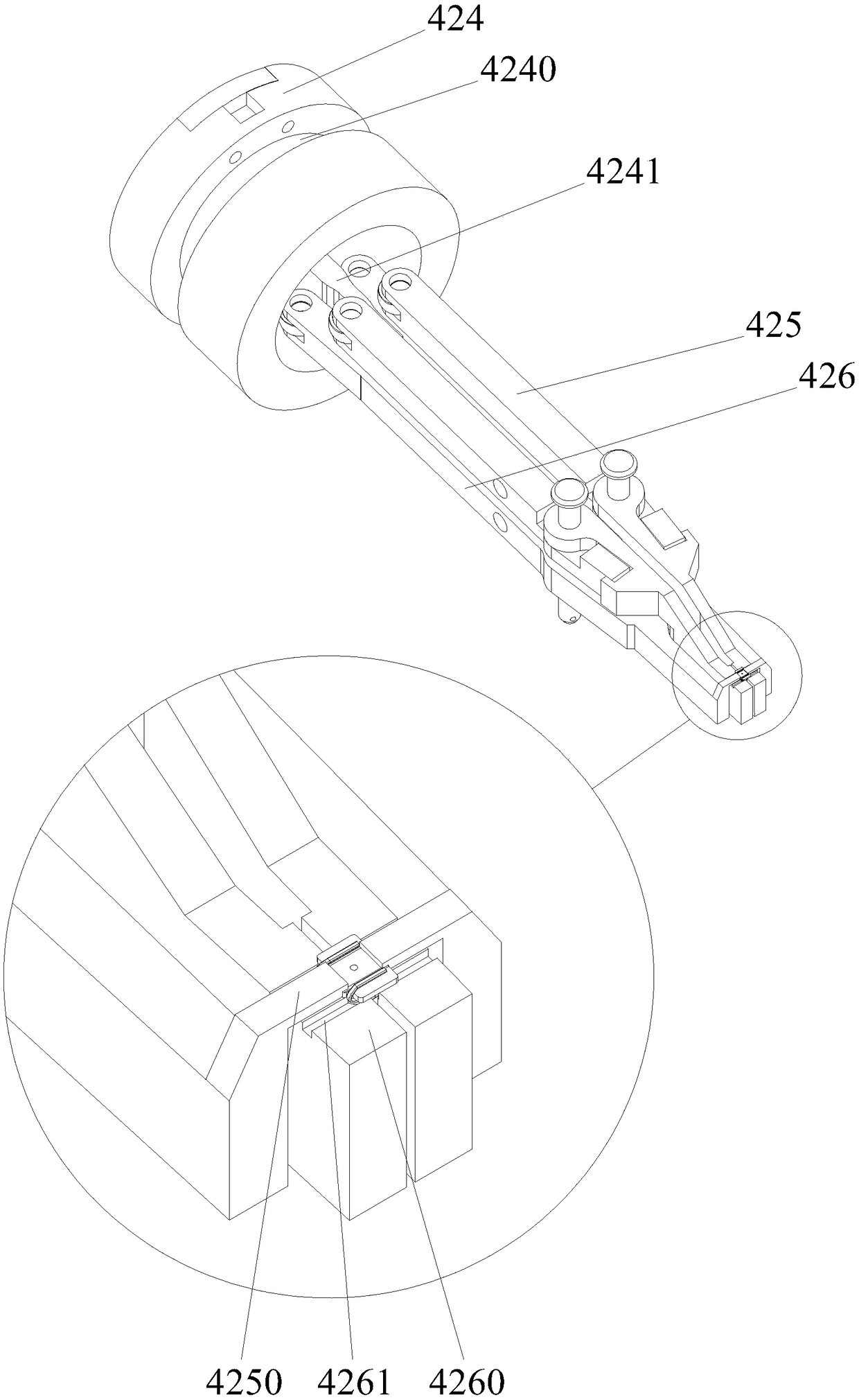

[0036] The aforementioned power unit 41 includes a driving wheel 410, a special-shaped groove, a driving bracket 411, a connecting rod, and a driving source 415. The driving bracket 411 and the driving source 415 are both arranged on the steering platform 401.

[0037] The aforementioned driving source 415 is provided on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com